1.2738 718H P20 + Ni Special Steel Plate and Steel Sheet

Guangzhou Changfeng Steel Co., Ltd.- Type:Steel Plate

- Standard:ASTM, AISI, GB, JIS, DIN, BS

- Certification:ISO, RoHS

- Surface Treatment:Black Surface

- Technique:Hot Rolled

- Application:Mold & Dies

Base Info

- Model NO.:HSSD 2738, AISI P20 Modified, 1.2738

- Special Use:High-strength Steel Plate, Wear Resistant Steel, Injection Molding

- Stock:Stock

- Grade:Hssd 2738,AISI P20 Modified

- Test:Ut 100% , SGS

- Delivery Quantiity:Include MOQ

- Place of Origin:China

- Application Hardness:28-36HRC

- Payment:30% Deposit,Blance by L,C at Sight or T,T

- Delivery Day:7-15 days

- Transport Package:Seaworthy Packing

- Specification:thickness: 21-300mm width: >=155mm, length: 5800mm

- Trademark:CF

- Origin:China

- HS Code:7225401000

- Production Capacity:1000tons,Month

Description

1.2738 Plate

Manufacturing process:

EF→LF→VD→Argon gas protection casting ingot→Multidirectional forging→Normalizing→Annealing heat treatment→UT→Quenching→Tempering pre-hardening heat treatment→Product testing

2, Applications of 1.2378/steel plate d2/die steel

A popular grade for toolmakers, 1.2378/steel plate d2/die steel is used in a wide variety of tool making applications. Typical applications include blanking dies and punches for sheet in stainless steel, brass, copper, zinc and hard abrasive materials generally. Other application include deep drawing dies, cupping dies, forming dies, sheet metal forming rolls, shear blades for strip and sheet including flying shears, circular cutters for cold rolled strip, trimmer dies, thread rolling dies, cold extrusion dies, broaches, plug gauges, ring gauges, special taps, straybolt taps, brick and tile mould liners, master hobs for cold hobbing plastic moulds and cut moulds for plastics.3, Delivery date

Stocked products: 7-15 days

Customized products: 30-50 days

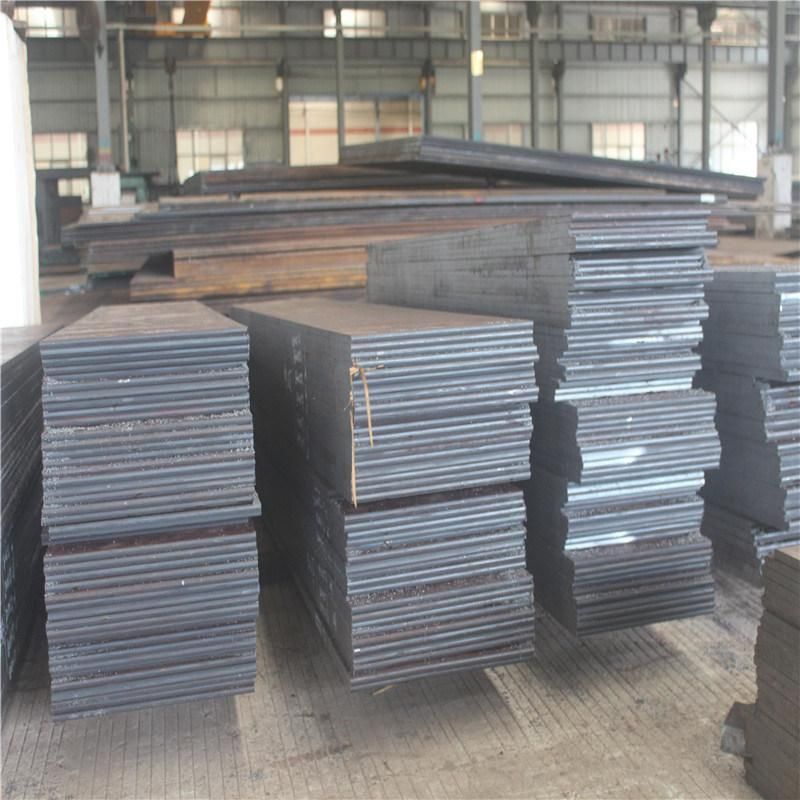

Product Photo

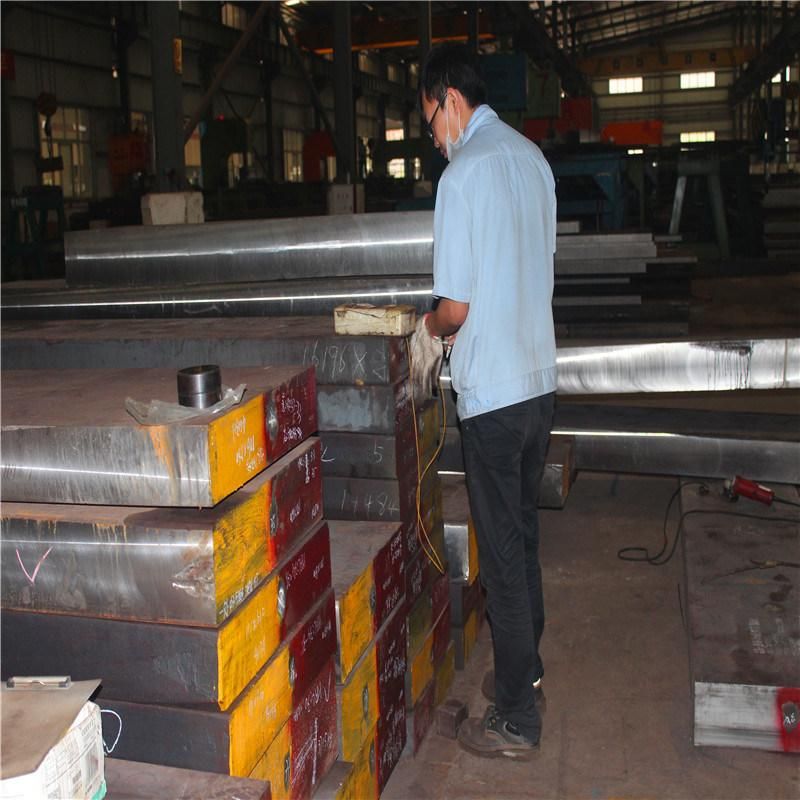

Quality inspection

Packing: Standard Export Packing or As per request

Forging of 1.2378/steel plate d2/die steel

Heat the 1.2378/steel plate d2/die steel tool steel slowly and uniformly to 700°C then more rapidly to 900-1040°C. After forging cool down slowly.

Annealing of 1.2378/steel plate d2/die steel

1.2378/steel plate d2/die steel is supplied in the annealed and machineable condition. Re-annealing will only be necessary if the steel has been forged or hardened by the toolmaker. To anneal, heat slowly and uniformly to 900°C. Soak for three to four hours and allow to cool in the furnace to room temperature. Re-heat to 800-1040°C and again soak for three to four hours. Allow to cool in the furnace to room temperature.Stress Relieving of 1.2378/steel plate d2/die steel

When tools made from 1.2378/steel plate d2/die steel tool steel are heavily machined, ground or otherwise subjected to cold work, the relief of internal strains is advisable before hardening to minimise the possibility of distortion. Stress relieving should be done after rough machining. To stress relieve, heat the component to 600-650°C. Soak well and cool in the furnace or in air. The tools may then be finish machined before hardening.

Hardening of 1.2378/steel plate d2/die steel

It is preferable to heat the tools in a controlled atmosphere. If this is not possible, pack hardening is recommended. A reducing atmosphere is desirable. Pre heat the 1.2378/steel plate d2/die steel tool steel component to 750-800°C. and allow to soak at this temperature. The tools may then be brought up to 1000-1040°C for air cooling, or 980°C for oil quenching. Soak thoroughly at the temperature for thirty minutes per 25mm of ruling section, then cool or quench accordingly. It is important not to exceed 1020°C when heating for hardening.Martempering of 1.2378/steel plate d2/die steel

Martempering is an alternative hardening procedure which may be used when suitable salt bath equipment is available. By this method internal strain, distortion and risk of quench cracking are reduced to the minimum. Pre-heat dry at 300-400°C. Pre-heat in salt at 800-850°C holding in the salt for ten minutes per inch of ruling section. Raise to the hardening temperature of 950-980°C holding in the salt for ten minutes per inch of ruling section. Marquench in salt at 230-250°C holding in the bath for five minutes 25mm of ruling section. Cool in still air. Tempering will be necessary.

Tempering of 1.2378/steel plate d2/die steel

Double tempering is recommended. Tempering of 1.2378/steel plate d2/die steel should be done with the least possible delay after hardening, preferably when the tools are still hand warm. Select a suitable tempering temperature, bearing in mind the service requirements. Heat slowly and uniformly. When the 1.2378/steel plate d2/die steel component has reached the desired temperature, soak for at least one hour per 25mm of section. The second tempering should be a repetition of the first.Heat treatment of 1.2378/steel plate d2/die steel

Heat treatment temperatures, including rate of heating, cooling and soaking times will vary due to factors such as the shape and size of each 1.2378/steel plate d2/die steel component. Other considerations during the heat treatment process include the type of furnace, quenching medium and work piece transfer facilities. Please consult your heat treatment provider for full guidance on heat treatment of tool steels.

Final Grinding of 1.2378/steel plate d2/die steel

Select the correct grade of wheel in consultation with the grinding wheel manufacturer. Ensure the grinding wheel is in good condition by means of a suitable dressing tool. Wet grinding is a preferable option using a copious supply of coolant. If dry grinding is resorted to then use a very soft wheel.

Our services:

1.Sizes material and others are all at your requirements and can be change

2.Price varies on material , dimensions, finished craft and different payments

3.We are direct manufacturer in machinery manufacturing with experience of many years

4.Detailed production design can be made according to the information you offered

5.Each material will be passed the UT test

6.We have an adequate inventory, so that we can effect a quick delivery