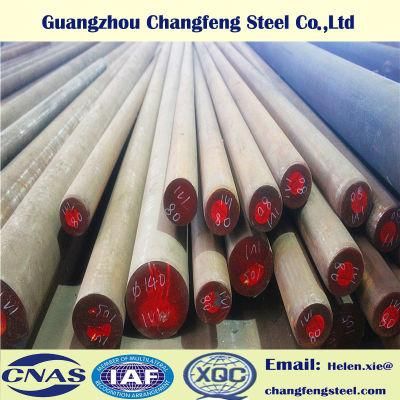

Cold Work round bar D3 SKD1 1.2080 Cr12

Guangzhou Changfeng Steel Co., Ltd.- Type:Special Steel Bar

- Standard:AISI, ASTM, DIN, JIS, GB, BS

- Composition:Mould Steel

- Technique:Hot Rolled

- Shape:Round

- Surface Treatment:Polished

Base Info

- Model NO.:D3,SKD1,1.2080,Cr12

- Special Use:High-strength Steel Plate

- Application:Tool Steel Bar

- Grade:D3,SKD1,1.2080

- Diameter:20-300mm

- Length:250-6000mm

- Test:SGS , Ut 100% , Element Testing

- Payment:30% Deposit,Blance by L,C at Sight or T,T

- Delivery Quatity:Include MOQ

- Delivery Time:For abundant stock, 15-20 days. For customized PRO

- Transport Package:Standard Export Packing or According to Customers′

- Specification:20-500mm

- Trademark:CF STEEL

- Origin:China

- HS Code:72254

- Production Capacity:1000t,Month

Description

MoNi SKD1 1.90 2.20 0.20 0.60 0.03 0.03 0.10 0.60 11.00 13.00 - - - - - -

5. Heat treatment regime

Start temperature 1000ºC. finished temperature 800°C

quench temperature 950~1000°C, oil cooling or force air cooling

6. Supply material: hot rolling, cold drawing, forged, hot rolled steel plate, cold draw steel wire spheroidizing annealing state, hardness 267~217HBw

7, Delivery Date

For abundant stock, 15-20 days.

For customized products, 30-50 days.

8. Packing: Standard export packing or according to customers' request.

9. About Us

Forging of D3 Cold Work Tool Steel

Pre-heat at 900-950°C then raise temperature to 1050-1100°C. Soak until uniformly heated. D3 tool steel is relatively hard at elevated temperature. Therefore, initial hammer blows must be light and the temperature must not be allowed to fall below 1020°C until the metal begins to flow. Final forging should not be done below 900°C.

Heat Treatment of D3 Cold Work Steel

Heat Treatment

D3 tool steel requires hardening and tempering to achieve maximum properties. For maximum accuracy, the parts of D3 tool steel should be stress relieved after roughing operations. Stress should be relieved at 648°C (1200°F) for one hour and cooled slowly.

Annealing

Heat D3 tool steels uniformly to 850-870°C, soak thoroughly, then slow furnace cool at a rate of not more than 25°C per hour to 650°C. The parts may then be air cooled. This should result in a maximum hardness of brinell 248.

Tempering

The D3 cold work steel should be cooled to room temperature and should be tempered immediately. The parts should be placed in the tempering furnace and increased slowly to the desired tempering temperature. Tempering for 1 hour per inch of thickness is required.

Hardening

D3 tool steel is extremely sensitive to overheating during hardening - do not overheat.

Pre heat slowly to 800-850°C, the raise rapidly to 950-970°C and soak until completely equalised. Quench in oil.

D3 SKD1 1.2080 Cr12 Tool Steel is a high carbon, high chromium, oilhardening tool steel thatis characterized by a relatively high attainable hardness and numerous, large, chromium rich alloy carbides in the microstructure. These carbides providegood resistance to wear from sliding contact with other metals and abrasive materials.

AISI D3 alloy steel is heat treatable and will offer a hardness in the range 58-64 HRC. After heat treatment D3 SKD1 1.2080 Cr12 tool steel is hard, durable and dense, and is immune from sinking in use. It offers a measure of corrosion resistance when polished. In general, the applications of AISI D3 tool steel resemble those of D2 tool steel but it should be remembered that alloy tool steel D3 has better wear resistance of the two steels and is preferred for such items as shear blades. Owing to its higher wear resistance, AISI / ASTM D3 cold work steel is slightly more difficult to grind than D2 steels.

5. Heat treatment regime

Start temperature 1000ºC. finished temperature 800°C

quench temperature 950~1000°C, oil cooling or force air cooling

6. Supply material: hot rolling, cold drawing, forged, hot rolled steel plate, cold draw steel wire spheroidizing annealing state, hardness 267~217HBw

7, Delivery Date

For abundant stock, 15-20 days.

For customized products, 30-50 days.

8. Packing: Standard export packing or according to customers' request.

9. About Us

Forging of D3 Cold Work Tool Steel

Pre-heat at 900-950°C then raise temperature to 1050-1100°C. Soak until uniformly heated. D3 tool steel is relatively hard at elevated temperature. Therefore, initial hammer blows must be light and the temperature must not be allowed to fall below 1020°C until the metal begins to flow. Final forging should not be done below 900°C.

Heat Treatment of D3 Cold Work Steel

Heat Treatment

D3 tool steel requires hardening and tempering to achieve maximum properties. For maximum accuracy, the parts of D3 tool steel should be stress relieved after roughing operations. Stress should be relieved at 648°C (1200°F) for one hour and cooled slowly.

Annealing

Heat D3 tool steels uniformly to 850-870°C, soak thoroughly, then slow furnace cool at a rate of not more than 25°C per hour to 650°C. The parts may then be air cooled. This should result in a maximum hardness of brinell 248.

Tempering

The D3 cold work steel should be cooled to room temperature and should be tempered immediately. The parts should be placed in the tempering furnace and increased slowly to the desired tempering temperature. Tempering for 1 hour per inch of thickness is required.

Hardening

D3 tool steel is extremely sensitive to overheating during hardening - do not overheat.

Pre heat slowly to 800-850°C, the raise rapidly to 950-970°C and soak until completely equalised. Quench in oil.

D3 SKD1 1.2080 Cr12 Tool Steel is a high carbon, high chromium, oilhardening tool steel thatis characterized by a relatively high attainable hardness and numerous, large, chromium rich alloy carbides in the microstructure. These carbides providegood resistance to wear from sliding contact with other metals and abrasive materials.

AISI D3 alloy steel is heat treatable and will offer a hardness in the range 58-64 HRC. After heat treatment D3 SKD1 1.2080 Cr12 tool steel is hard, durable and dense, and is immune from sinking in use. It offers a measure of corrosion resistance when polished. In general, the applications of AISI D3 tool steel resemble those of D2 tool steel but it should be remembered that alloy tool steel D3 has better wear resistance of the two steels and is preferred for such items as shear blades. Owing to its higher wear resistance, AISI / ASTM D3 cold work steel is slightly more difficult to grind than D2 steels.