D2 SKD11 Cold Work alloy mould Tool Steel bar

Guangzhou Changfeng Steel Co., Ltd.- Technique:Hot Rolled

- Standard:AISI, JIS, ASTM, DIN, GB

- Certification:IS0, RoHS

- Ut Class:According to Standard of Sep 1921,84, 100% Volume

- Melting Process:Eaf+ESR

- Thickness:6-160mm

Base Info

- Model NO.:1.2379,D2,SKD11,Cr12Mo1V1

- Width:155-610mm

- Diameter:14-80mm

- Length:4000-6000mm

- Process Technique:Forged or Hot Rolled

- Payment Term:30% Deposit, Blance by L,C at Sight or T,T

- Surface Treatment:Black, Grinded, Machined

- Transport Package:Export Standard Packing or Customers′demand

- Specification:On request

- Trademark:CHANGCHENG STEEL

- Origin:China

- HS Code:7228

- Production Capacity:1000t,Month

Description

Hardness

(HRC)First preheating Second preheating Last heating 600-650 800-850 1020-1040 Air Cooling 61-63 500-560 2 ≥58

4, SKD11 Hardness: Annealing 235 ~ 205 HB, Quenching ≥50 HRC

5, Delivery Detail: For abundant stock, 15-20 days.For customized products, 30-50 days.

6, Terms of payment: 30% deposit T/T and the balance by L/C at sight, or 100%T/T

(HRC)

4, SKD11 Hardness: Annealing 235 ~ 205 HB, Quenching ≥50 HRC

5, Delivery Detail: For abundant stock, 15-20 days.For customized products, 30-50 days.

6, Terms of payment: 30% deposit T/T and the balance by L/C at sight, or 100%T/T

7, Delivery condition:

EAF or ESR, Hot rolled or Forged, machined material,Annealing or Q+T

Factory Hardness: HBS=160-235.

8, Ultrasonic test standards: SEP1921-84 GR.3 CLASS D/D

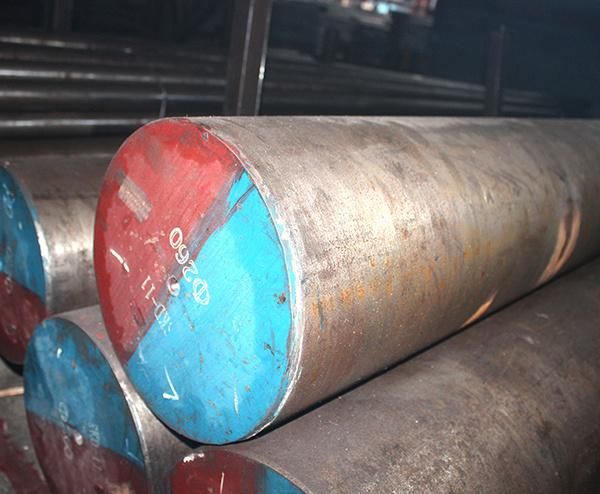

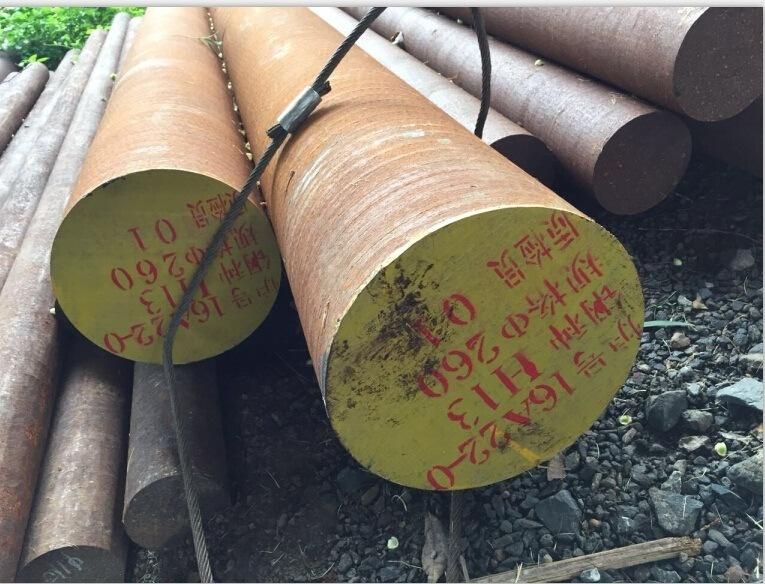

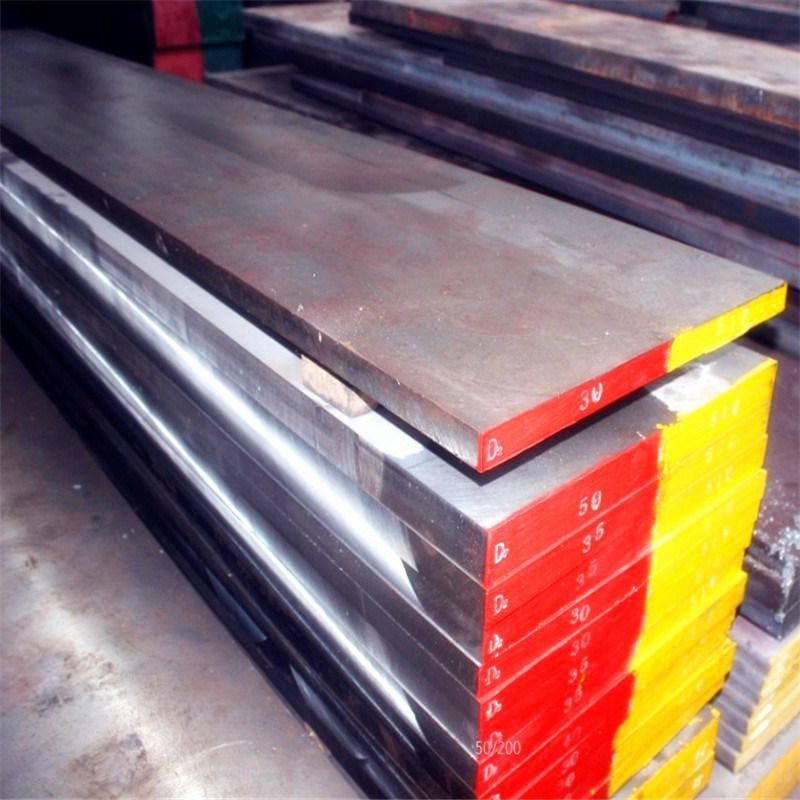

Picture shows

We are looking forward to establishing a long-term partnership with you!

Send your inquiry details in the below, click "send" now!