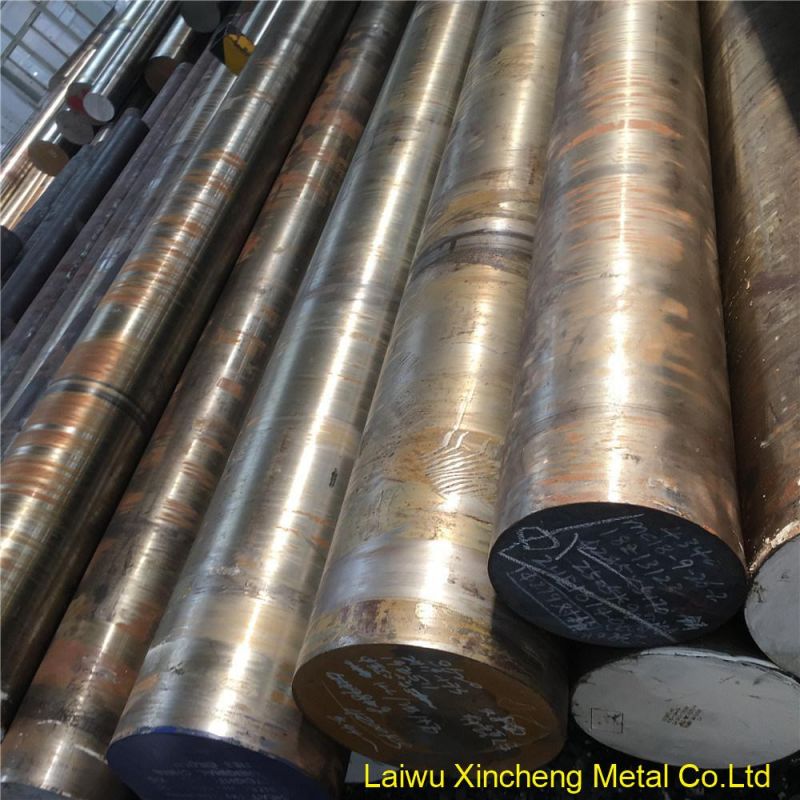

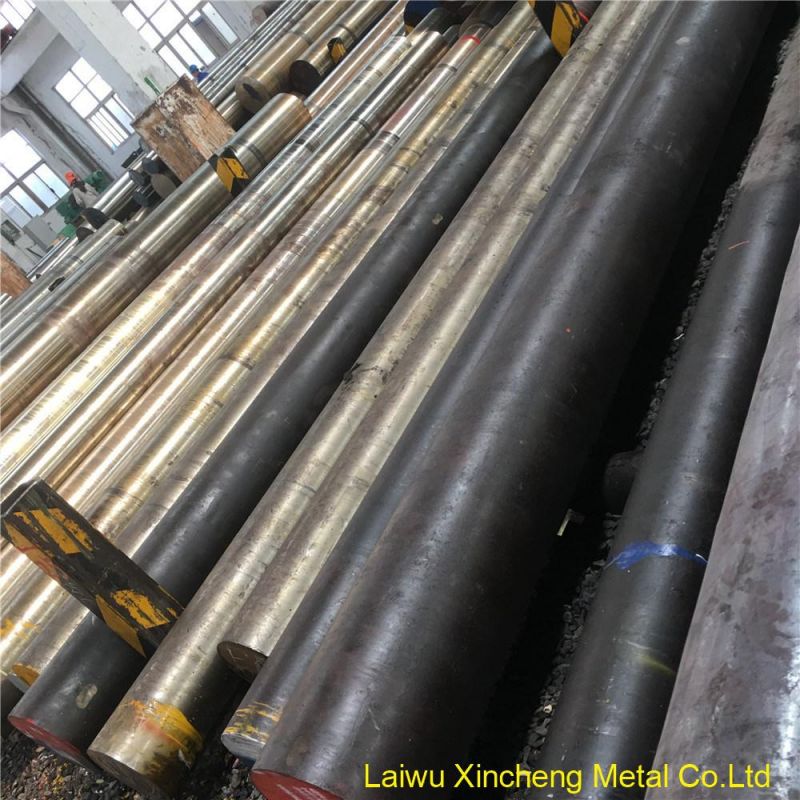

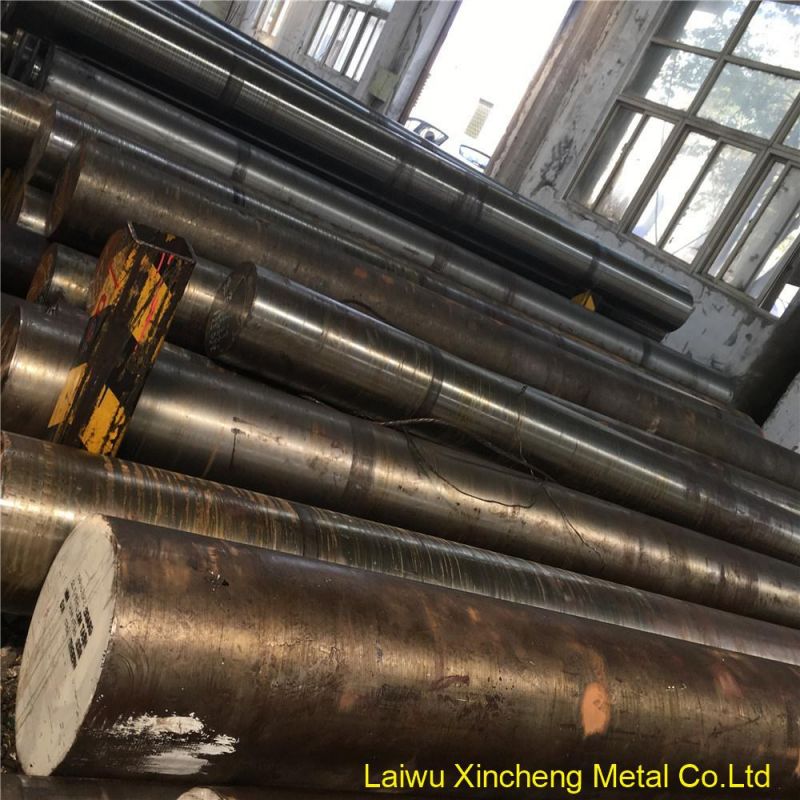

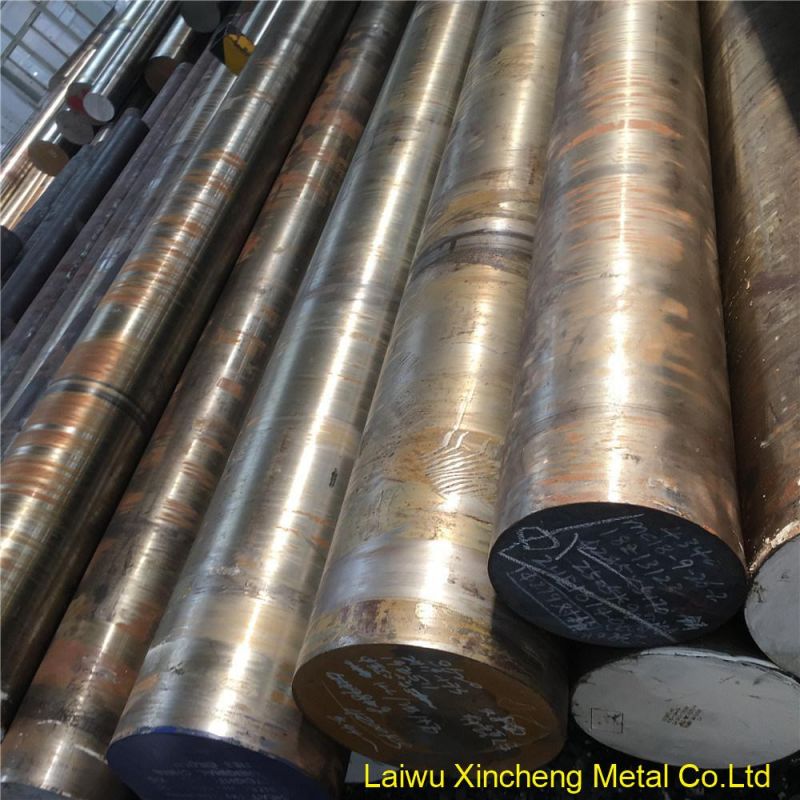

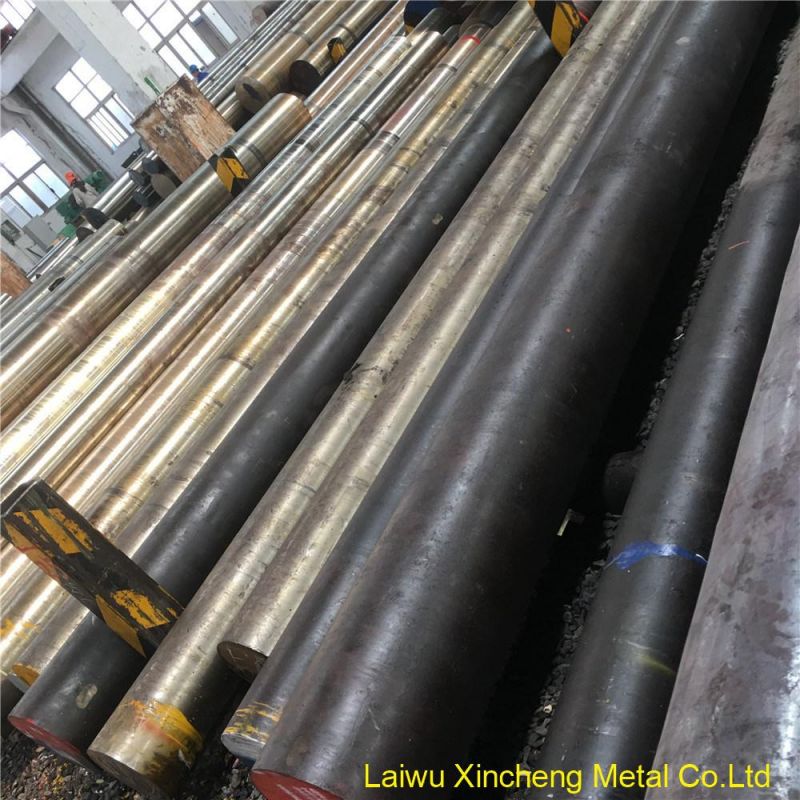

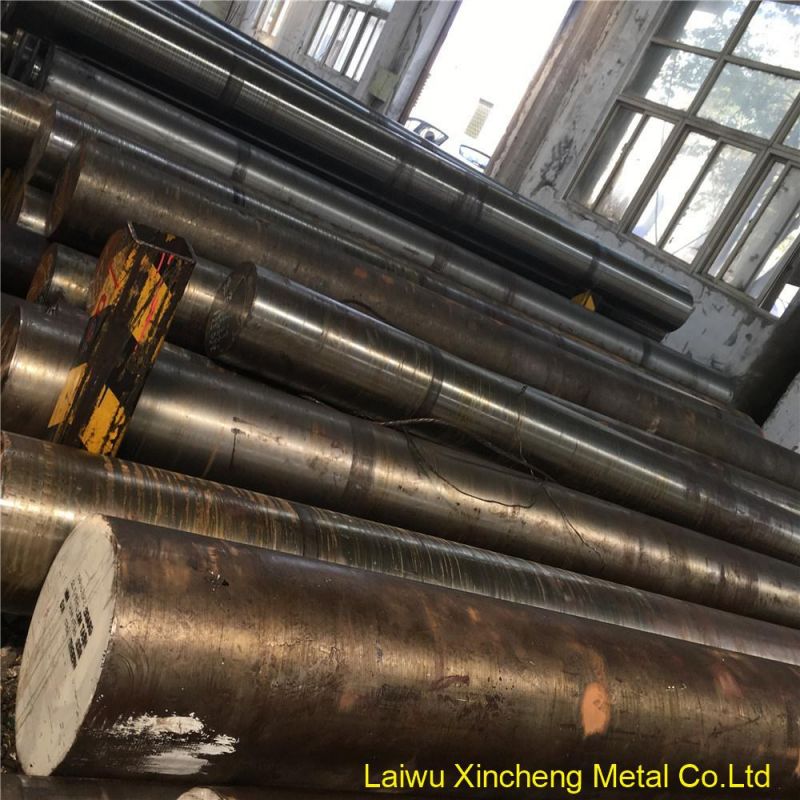

18crnimo7-6 18crnimo7 18ncd6 1.6587 820A16 Forged Steel Round Square Bar Ut Tested

Laiwu Xincheng Metal Co., Ltd.- Application:Structural Steel Bar, Tool Steel Bar, Die Steel Bar

- Technique:Forged

- Standard:AISI, ASTM, GB, JIS, DIN, BS

- Type:Alloy Steel Bar

- Surface Treatment:Rough Turned

- Alloy:Alloy

Base Info

- Specification:200-1000mm

- Transport Package:Standard Sea Worthy

- MOQ:1PCS

- Standards:18crnimo7-6 (1.6587)T 17CrNiMo6 17crnimo7 18ncd6 8

- Commodities:Forged Steel Square Bar

- Commodity:Forged Steel Round Bar

- Origin:China

- Production Capacity:3000tons,Month

Description

18CrNiMo7-617CrNiMo6 18NCD6 820A16 18NiCrMo7 17Cr2Ni2Mo 511 18CrNiMo7 17CrNiMo7

6.Chemical composition of 18CrNiMo7-6 18CrNiMo7 18NCD6 1.6587 820A16

7.HEAT TREATMENT OF 18CrNiMo7-6 18CrNiMo7 18NCD6 1.6587 820A16 FORGED STEEL

1. Melting Process: EAF/BOF+LF+VD resulting in ingots

2. Both ends cut by saw

3. Ratio of forging:minimum 3:1

4. Grain size of final product: according to ASTM E112 more than 5,preferred more than 8

5. Ultrasonic test: As per SEP1921 Class C/c or D/d

9.MOQ: one piece per size/grade

10.Payment term: FOB CIF CFR EXW and so on

11.Delivery time : 7 to 30 days after deposit received.

12.Mark on both ends

Heat number, size, Length,grades, Weight,Origin (as per contract), or other as required

18CrNiMo7-6 18CrNiMo7 18NCD6 1.6587 820A16

18CrNiMo7-6 18CrNiMo7 18NCD6 1.6587 820A16

18CrNiMo7-6 18CrNiMo7 18NCD6 1.6587 820A16

6.Chemical composition of 18CrNiMo7-6 18CrNiMo7 18NCD6 1.6587 820A16

| C | Si | Mn | Ni | P | S | Cr | Mo |

| 0.15 - 0.21 | max 0.4 | 0.5 - 0.9 | 1.4 - 1.7 | max 0.025 | max 0.035 | 1.5 - 1.8 | 0.25 - 0.35 |

7.HEAT TREATMENT OF 18CrNiMo7-6 18CrNiMo7 18NCD6 1.6587 820A16 FORGED STEEL

- Soft Annealing: Heat 17CrNiMo6 to 650-700oC, cool slowly in furnace. This will produce a maximum Brinell hardness of 229.

- Normalizing: 850-880oC, air.

- Hardening: Carburising: 880-980oC. Core Hardening: 830-870oC, water. Case Hardening: 780-820oC, water.

- Tempering:Temperature: 150-200oC

1. Melting Process: EAF/BOF+LF+VD resulting in ingots

2. Both ends cut by saw

3. Ratio of forging:minimum 3:1

4. Grain size of final product: according to ASTM E112 more than 5,preferred more than 8

5. Ultrasonic test: As per SEP1921 Class C/c or D/d

9.MOQ: one piece per size/grade

10.Payment term: FOB CIF CFR EXW and so on

11.Delivery time : 7 to 30 days after deposit received.

12.Mark on both ends

Heat number, size, Length,grades, Weight,Origin (as per contract), or other as required

18CrNiMo7-6 18CrNiMo7 18NCD6 1.6587 820A16

18CrNiMo7-6 18CrNiMo7 18NCD6 1.6587 820A16

18CrNiMo7-6 18CrNiMo7 18NCD6 1.6587 820A16