JIS G4051 S45c Forged Steel Round Bar / Sep 1921 Ut S45c Forged Steel Bar

Laiwu Xincheng Metal Co., Ltd.- Application:Structural Steel Bar, Tool Steel Bar, Die Steel Bar

- Technique:Forged

- Standard:AISI, ASTM, GB, JIS, DIN, BS

- Type:Alloy Steel Bar

- Alloy:Alloy

- Special Use:Alloy Steel

Base Info

- Transport Package:Standard Sea Worthy

- Grades:1.1191 C45 S45c 1045

- MOQ:One Piece

- Heat Treatment:Annealed, Normalized, Qt

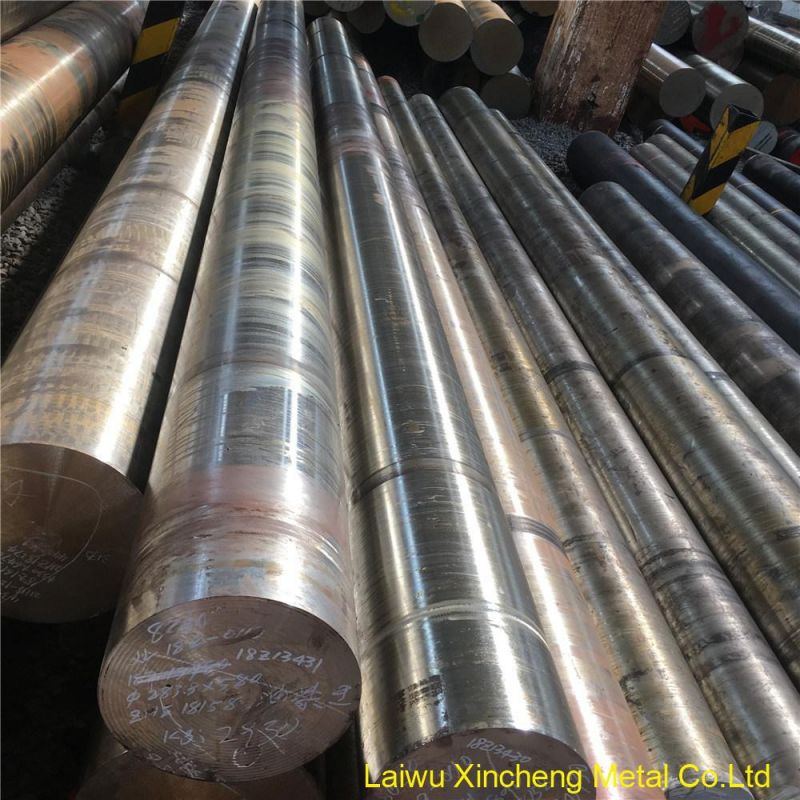

- Delivery Condition:Forged , Forged+Rough Turned

- Model NO.:JIS G4051 S45C

- Specification:200-1000mm

- Origin:China

- Production Capacity:3000tons,Month

Description

Basic Info.

Model NO. JIS G4051 S45C Delivery Condition Forged / Forged+Rough Turned Heat Treatment Annealed, Normalized, Qt MOQ One Piece Grades 1.1191 C45 S45c 1045 Transport Package Standard Sea Worthy Specification 200-1000mm Origin China Production Capacity 3000tons/MonthProduct Description

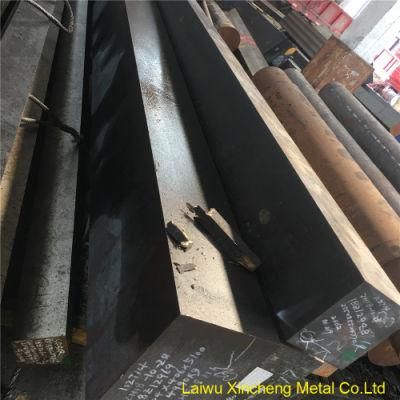

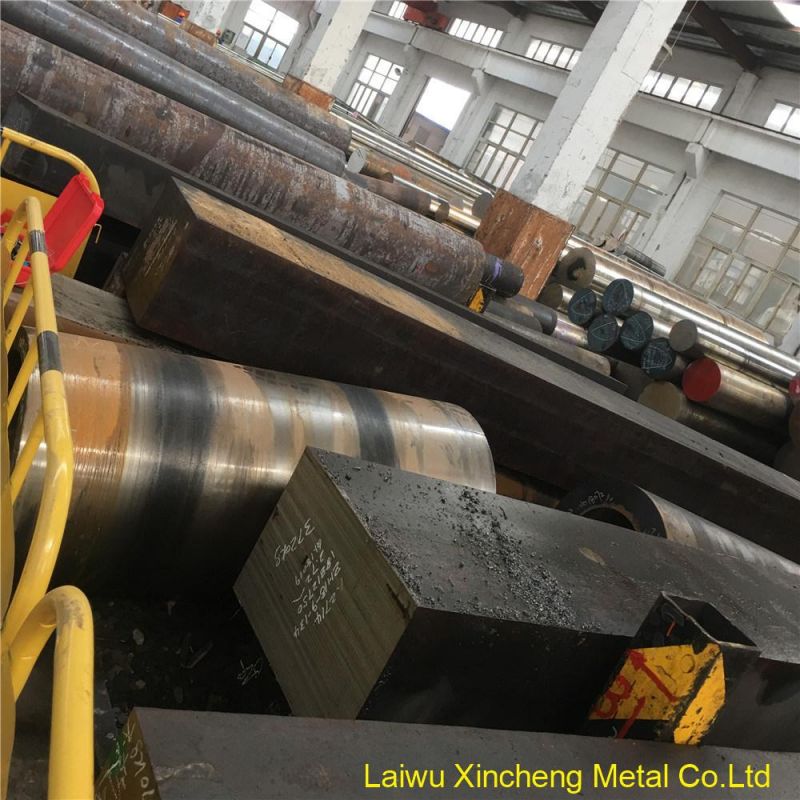

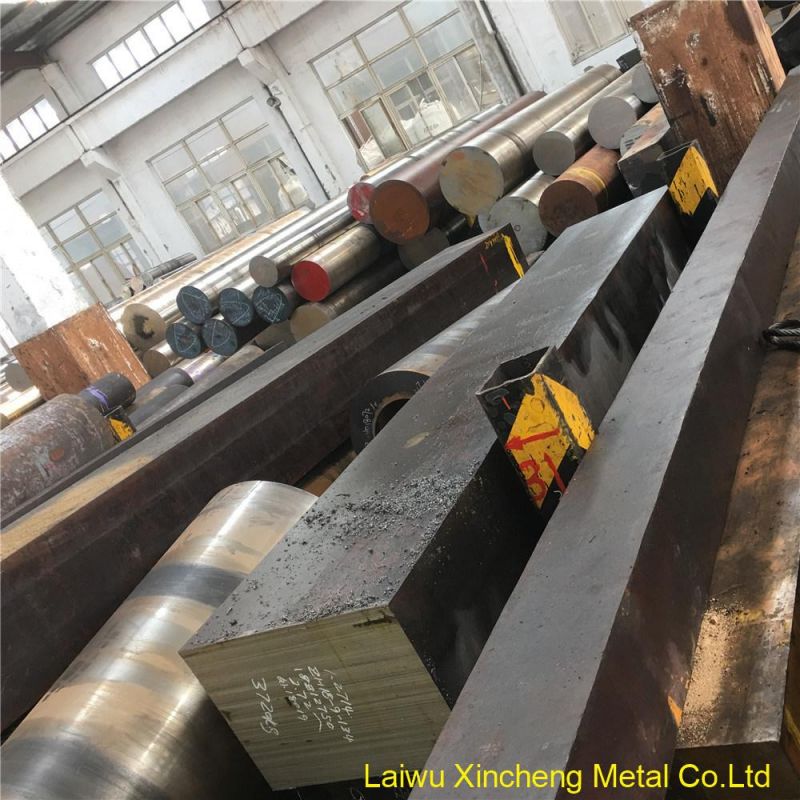

JIS G4051 S45C Forged Steel Round Bar / SEP 1921 UT S45C Forged Steel Bar1.JIS G4051 S45C forged steel bar sizes we can offer;

Round bar: 200-1000mm

Square bar:150×150-600×600mm

2.Supply condition for JIS G4051 S45C Forged steel bars:Black /Rough Machined /Rough turned

3.JIS G4051 S45C Forged Steel round bar tolerance:

Black surface

Forged sizes up to 500mm (-0/+5mm)

Forged sizes above 500mm in diameter (-0/+8mm)

Machined surface to all sizes (-0/+3mm)

4.Futhur heat treatment for JIS G4051 S45C forged steel :

Normalized

Annealed

Q&T(Quenched&Tempered)

5.JIS G4051 S45C Steel Equivalent

AFNOR XC 42 TS AFNOR XC 45 AFNOR XC 48 AFNOR XC42

DIN 1.1191 JIS S 45C JIS S 48 C SS 1672

ASTM A29 ASTM A510 ASTM A519 ASTM A576

FED QQ-S-635 (C1045) FED QQ-S-700 (1045) SAE J403 ASTM A682

SAE J414 ASTM A183 (2-Nuts) ASTM A236 (1045) SAE J412

ASTM A266 (1045) ASTM A827 ASTM A830 QQ S700 (C1045)

SAE J1397 (1045)

6.JIS G4051 S45C Forged steel chemical composition

| Standard | Grade | C | Si | Mn | P | S |

| GB/T699 | 45 | 0.42-0.5 | 0.17-0.37 | 0.5-0.8 | 0.035 | 0.035 |

| JIS G4051 | S45C | 0.42-0.48 | 0.15-0.35 | 0.6-0.9 | 0.03 | 0.035 |

| ASTM A29/A29M | 1045 | 0.43-0.5 | 0.15-0.35 | 0.6-0.9 | 0.04 | 0.05 |

| EN 10083-2 | C45E/1.1191 | 0.43-0.5 | 0.4 | 0.5-0.8 | 0.03 | 0.035 |

7.JIS G4051 S45C Forged steel Application

Gears Pins Rams

Shafts Rolls Sockets

Axles Spindles Worms

Bolts Ratchets Light gears

Studs Crankshafts Guide rods

Connecting rods Torsion bars Hydraulic clamps

8.Quality control:

1. Melting Process: EAF/BOF+LF+VD resulting in ingots

2. Both ends cut by saw

3. Ratio of forging:minimum 3:1

4. Grain size of final product: according to ASTM E112 more than 5,preferred more than 8

5. Ultrasonic test: As per SEP1921 Class C/c or D/d

9.Heat treatment of JIS G4051 S45C

Forging

Heat to 850°C - 1250°C (1562°F - 2282°F)

Hold until the temperature is uniform

Cool in furnace

Annealing

Heat to 800°C - 850°C (1472°F - 1562°F)

Hold until the temperature is uniform

Cool in furnace.

Normalizing

Heat to 870°C - 920°C (1598°F-1688°F)

Hold until the temperature is uniform

Soak for 10 - 15 minutes

Cool in still air

Stress Relieving

Heat to 550°C - 660°C (1022°F - 1220°F)

Hold until the temperature is uniform

Soak for 1 hour per 25mm of section

Cool in still air

Hardening

Heat to 820°C - 850°C (1508°F - 1562°F)

Hold until the temperature is uniform

Soak for 10 - 15 minutes per 25mm of section

Quench in water or brine

Tempering

Re-heat to 400°C - 650°C (752°F - 1202°F ) as required

Hold until the temperature is unifo

10.MOQ: one piece per size/grade

11.Payment term: FOB CIF CFR EXW and so on

12.Delivery time : 7 to 30 days after deposit received.

JIS G4051 S45C Forged Steel Round Bar / SEP 1921 UT S45C Forged Steel Bar

JIS G4051 S45C Forged Steel Round Bar / SEP 1921 UT S45C Forged Steel Bar

JIS G4051 S45C Forged Steel Round Bar / SEP 1921 UT S45C Forged Steel Bar