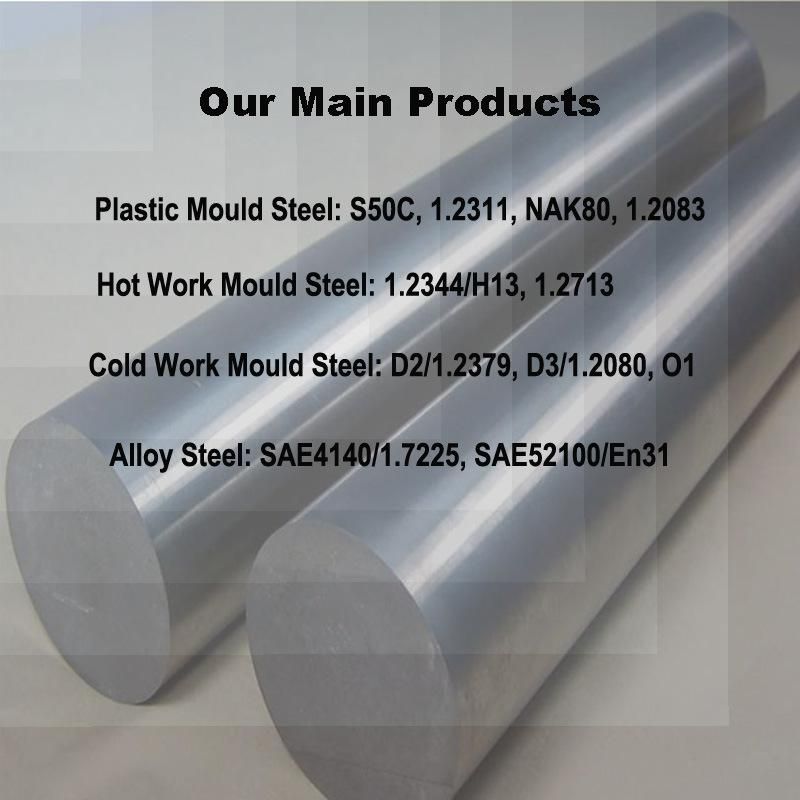

1.6523/SAE8620 Hot Rolled Alloy Steel Round Bar for Mechanical

Guangzhou Changfeng Steel Co., Ltd.- Type:Alloy Steel Bar

- Standard:AISI, ASTM, GB, JIS, DIN, BS

- Technique:Hot Rolled

- Application:Tool Steel Bar

- Surface Treatment:Black, Grinded, Machined

- Alloy:Alloy

Base Info

- Model NO.:1.6523, SAE8620, 20CrNiMo

- Special Use:Mold Steel, Free Cutting Steel

- Heat Treatment:Annealing,Q+T

- Test:SGS,Ut 100%,Element Testing

- Certificate:ISO ,Mill Certificate

- Grade:1.6523, SAE8620, 20CrNiMo

- Payment:30%Deposit, Blance by L,C at Sight or T,T

- Delivery Quatity:Include MOQ

- Transport Package:Export Standard Packing or Customers′demand

- Specification:diameter 20-100mm

- Trademark:CF STEEL

- Origin:China

- HS Code:7228300000

- Production Capacity:1000t,Month

Description

Basic Info.

Model NO. 1.6523, SAE8620, 20CrNiMo Special Use Mold Steel, Free Cutting Steel Heat Treatment Annealing/Q+T Test SGS/Ut 100%/Element Testing Certificate ISO /Mill Certificate Grade 1.6523, SAE8620, 20CrNiMo Payment 30%Deposit, Blance by L/C at Sight or T/T Delivery Quatity Include MOQ Transport Package Export Standard Packing or Customers′demand Specification diameter 20-100mm Trademark CF STEEL Origin China HS Code 7228300000 Production Capacity 1000t/MonthProduct Description

1.6523/SAE8620 Hot Rolled Alloy Steel for MechanicalChemical Composition

| C | Si | Mn | Cr | Ni | Mo | S | P |

| 0.18-0.23 | 0.15-0.35 | 0.70-0.90 | 0.40-0.60 | 0.40-0.70 | 0.15-0.25 | ≤0.035 | ≤0.035 |

1. Feature:

1) Demand has high yield strength, tensile strength and fatigue strength, there has enough plasticity

and toughness;

2) Demanding by refining outside the furnace, vacuum electroslag remelting or processing, or double vacuum smelting, vacuum induction furnace smelting suitable heat treatment;

3) Corrosion resistant steel, heat-resistant steel, wear-resistant steel, magnetic steel, and other

special physical and chemical properties of the steel;

2. Application:

1) Zinc, aluminum, magnesium and other alloy die-casting molds;

2) Heat dies and all kinds of hot forged molds;

3) Metal extrusion die holder.

3. Ready Stock:

Round bar dia20-100mm black surface and hot rolled deliver condition.

4. Heat Treatment

1) Preheating 2-4 hours in 500-600°C;

2) Keeping temperature for 2 hours in 850-880°C;

3) Oil cooling to reach 50-100°C;

4) After quenching can reach a hardness of 50-52HRC, then tempered at 200°C,

then hardness can reach above 48 HRC.

5. Melting Process

1) EAF:Electric Furnace+LF+VD (Optional);

2) ESR:Electric Furnace+LF+VD+Eleroslag Remelted (Optional).

6. Packaging Details:

Packed with plastic film, seaworthing packing, others according to customers' requirements;

7. Delivery time:

For abundant stock, 15-20 days.For customized products, 30-50 days.

All the sizes as require can be customerized as fresh production with MOQ,products of required specifications can be developed/produced per international, chinese or industry standards, or based on agreements with customers.

Product pictures:

Corner of factory: