High Speed Alloy Special Steel (1.3247/M42)

Guangzhou Changfeng Steel Co., Ltd.- Type:Steel Plate

- Standard:AISI, ASTM, DIN, JIS, GB, BS

- Composition:Alloy Steel

- Technique:Hot Rolled

- Shape:Plate

- Surface Treatment:Black, Grinded, Machined

Base Info

- Model NO.:1.3247, M42, SKH59, W2Mo9Cr4VCo8

- Special Use:Wear Resistant Steel, Free Cutting Steel, Mold Steel

- Application:Die Steel Bar

- Thickness:5mm-800mm

- Length:100mm-5800mm

- Width:50mm-22000mm

- Grade:1.3247, M42, Skh59, W2mo9cr4vco8

- Annealed Hardness:255hbs

- Certificate:ISO , Mill Certificate

- Test:SGS , Ut 100% , Element Testing

- Payment:30% Deposit, Blance by L,C at Sight or T,T

- Delivery Quantity:Include MOQ

- Transport Package:Export Standard Packing or Customers′demand

- Specification:According to customer requirements

- Trademark:CF STEEL

- Origin:China

- HS Code:7225401000

- Production Capacity:1000t,Month

Description

Basic Info.

Model NO. 1.3247, M42, SKH59, W2Mo9Cr4VCo8 Special Use Wear Resistant Steel, Free Cutting Steel, Mold Steel Application Die Steel Bar Thickness 5mm-800mm Length 100mm-5800mm Width 50mm-22000mm Grade 1.3247, M42, Skh59, W2mo9cr4vco8 Annealed Hardness 255hbs Certificate ISO / Mill Certificate Test SGS / Ut 100% / Element Testing Payment 30% Deposit, Blance by L/C at Sight or T/T Delivery Quantity Include MOQ Transport Package Export Standard Packing or Customers′demand Specification According to customer requirements Trademark CF STEEL Origin China HS Code 7225401000 Production Capacity 1000t/MonthProduct Description

High Speed Alloy Special Steel (1.3247/M42)M42 Grade:W2Mo9Cr4VCo8/M42/1.3247/SKH59

M42 steel (W2Mo9Cr4VCo8) is a high toughness cobalt high speed steel, which is mainly used for high toughness and wear resistant metal cold stamping die,also can be used in cutting tools and knife cooling.

1) suitable for making various strong cutting tool.

2) used to produce all kinds of high hard and super hard saw blade, drill, tap, broach, gear hob and various kinds of milling cutter.

3) used for advanced punching die, screw die, and the toughness and complicated shape of the punch, etc.

4) used for cold forging die and drawing mode, etc.

5) recommended watch case factory, screw factory and other cold stamping products industry use.

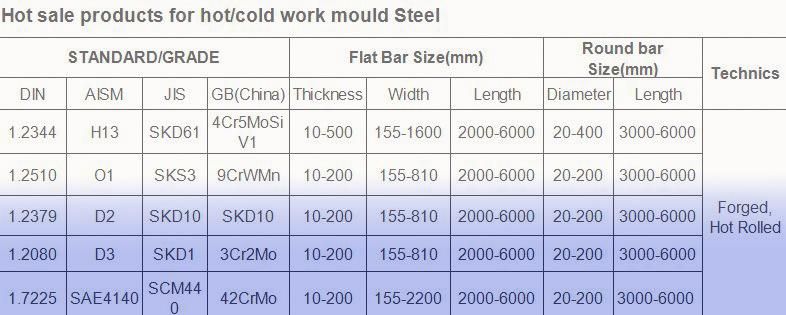

Chemical composition(%)

| C | Si | Mn | P | S | Cr | V | W | Mo | Co |

| 1.00~1.15 | ≥0.65 | ≥0.40 | ≥0.030 | ≥0.030 | 3.50~4.50 | 0.95~1.35 | 1.15~1.85 | 9.0~10.0 | 7.50~8.50 |

Deliver Condition:

The annealed hardness ≤269HBW, the cold drawn hardness ≤285HBW, after cold drawn annealed hardness ≤277HBW

Packing: Export Standard Packing or Customers' demand

Delivery time:

For abundant stock, 15-20 days.For customized products, 30-50 days.

Payment term:

T/T 30% in advance, 70% balance against BL copy.

T/T 30% as deposite, 70% balance L/C at sight.

100% Trade Assurance.

Why Choose Us:

1. Competitive price and quality from our own factory

2. Approved by ISO9001, CE, SGS every year

3. Best service with 24 hours reply

4. Flexible payment with T/T,L/C , Trade Assurance

5. Smooth production ability(1000tons/month)

6. Quick delivery and standard exporting package

7. OEM/ODM

All the sizes as require can be customerized as fresh production with MOQ,products of required specifications can be developed/produced per international, chinese or industry standards, or based on agreements with customers.

Corner of factory: