DIN17175 St35.8 St45.8 Carbon Steel Boiler Tubes

Guangzhou Kingmetal Steel Industry Co., Ltd.- Type:Seamless

- Technique:Cold Rolled

- Material:Carbon Steel

- Surface Treatment:Black

- Usage:Pipeline Transport, Boiler Pipe

- Section Shape:Round

Base Info

- Model NO.:EL-BT

- Thickness:1.2 - 9.5mm

- Length:1-12m

- Delivery Time:15-30 Days After Down Payment

- Standard or Not:Standard

- Alloy or Not:Is Alloy

- Secondary or Not:Non-Secondary

- Price Term:Fob,CIF,CNF

- Payment:L,C,T,T

- MOQ:as Requested

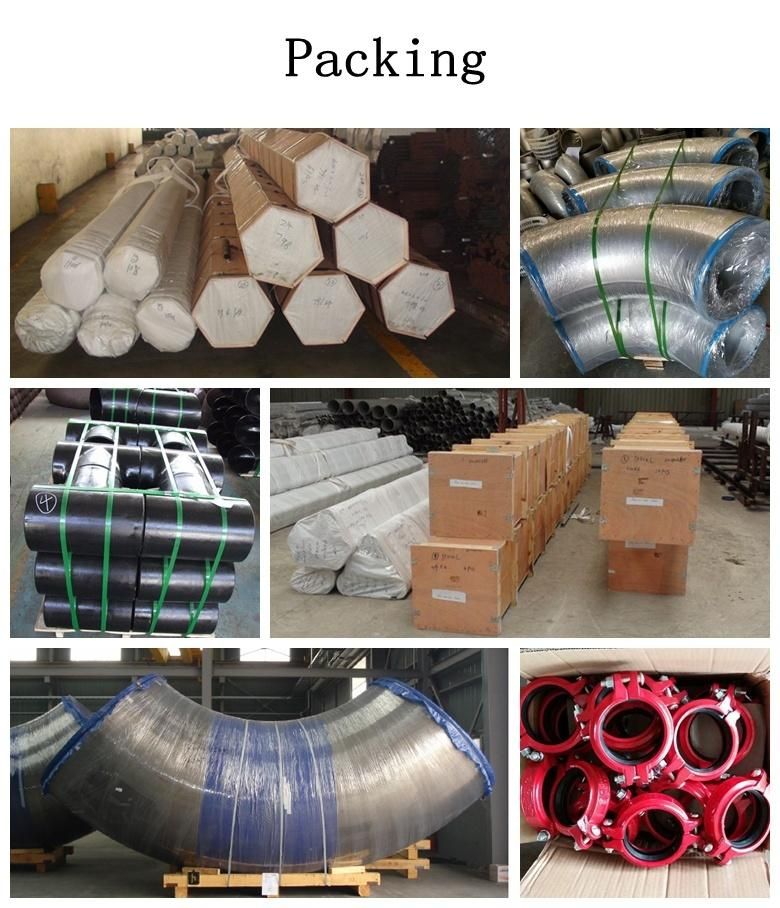

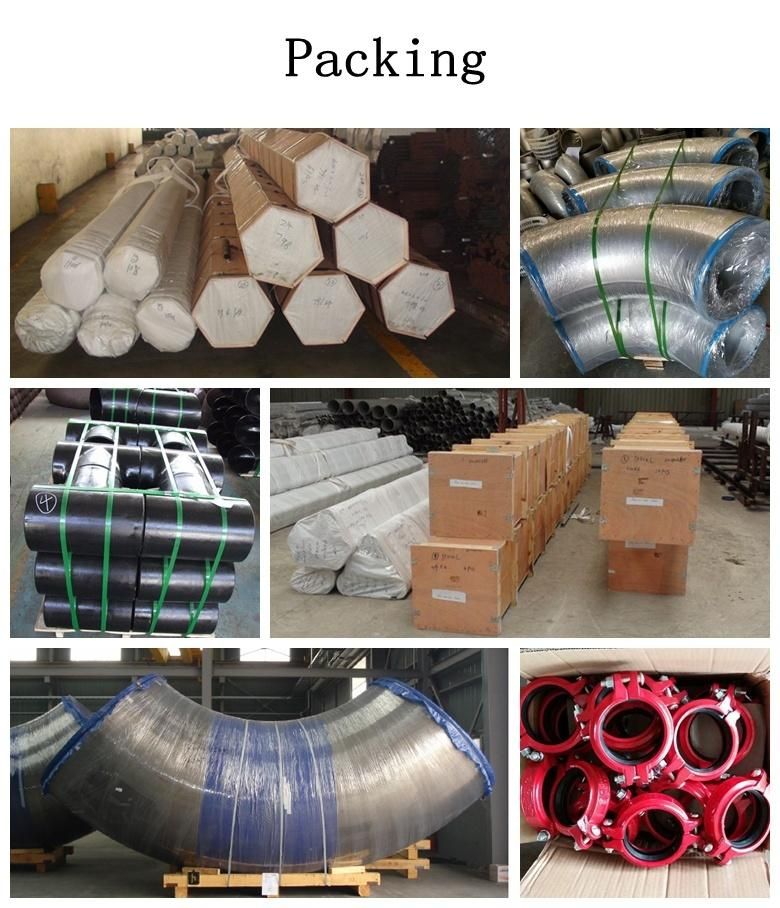

- Transport Package:in Bundles or as Per Customer′s Request

- Specification:15.9- 139.8mm

- Trademark:Kingmetal

- Origin:China (Mainland)

- HS Code:730419

- Production Capacity:20000 Tons,Month

Description

A106 GR.A/GR.B/GR.C

A179/A192

A210 GR.A1/GR.C

A209 GR.T1/GR.T1a/GR.T1b

A213 T1/T2/T5/T11/T12/T22

A335 GR.1/GR.6

A556 GR.A2/GR.B2/GR.C2

STPG370/STPG410/STB340/STB510/STBL380

STBA12/STBA13/STBA20/STBA22/STBA23/STBA24/STBA25

STF340/STFA12/STFA22/STFA23/STFA24

DIN 17175 ST35.8/ST45.8/13CrMo44/10CrMo9-10

EN10216-1 P195 TR1/2,P235 TR1/2,P265TR1/2

EN10216-2 P195GH,P235GH,P265GH,16Mo3,13CrMo4-5,10CrMo9-10Standard ASTM A213/ASME SA213,ASTM A335/ASME SA335, A369, A209, A250; JIS G3462, JIS G3467, DIN17175, BS3059-2, GB/T8162, GB/T6479, GB/T9948, GB5310, ASTM A179/ASME SA179,ASTM A192/ASME SA192, ASTM A334/ASME SA334,etc.

Description

Surface FinishTreatment : Annealing and Pickling, Matt Finish or Satin Finish

Mirror Finish, Wire Drawing or Hairline Finish

Roughness Average : 0.1~0.2μm Outside, 0.3~0.4μm Inside. Ends Finish Plain Ends or Beveled Ends Test Eddy Current/ Hydrostatic/ Ultrasonic/ Intergranular Corrosion

Or according to customers' request

Application: Petroleum, chemical industry, electric power, boiler, high temperature resistant,

low temperature resistant, corrosion resistant alloy pipe used.

Material and Standard Item Chinese Standard American Standard German Standard 1) 10# A53A St37

A106A St37-2 DIN17175 A179C St35.8 DIN1629

2)

20#ASTMA106-B St45-8 DIN17175 ASTMA53-B St42-2 DIN1626 ASTMA178-C St45-4 DIN1629 3)

45#

ASTMA1045 CK45

4)

16Mn

ASTMA210-C St52 DIN1629/3 St52.4 DIN1629/4 5) 37Mn5 J55

A179/A192

A210 GR.A1/GR.C

A209 GR.T1/GR.T1a/GR.T1b

A213 T1/T2/T5/T11/T12/T22

A335 GR.1/GR.6

A556 GR.A2/GR.B2/GR.C2

STPG370/STPG410/STB340/STB510/STBL380

STBA12/STBA13/STBA20/STBA22/STBA23/STBA24/STBA25

STF340/STFA12/STFA22/STFA23/STFA24

DIN 17175 ST35.8/ST45.8/13CrMo44/10CrMo9-10

EN10216-1 P195 TR1/2,P235 TR1/2,P265TR1/2

EN10216-2 P195GH,P235GH,P265GH,16Mo3,13CrMo4-5,10CrMo9-10

Description

Surface Finish

Mirror Finish, Wire Drawing or Hairline Finish

Roughness Average : 0.1~0.2μm Outside, 0.3~0.4μm Inside.

Or according to customers' request

Application: Petroleum, chemical industry, electric power, boiler, high temperature resistant,

low temperature resistant, corrosion resistant alloy pipe used.

2)

20#