1.3247/M42 High Speed Alloy Steel Bar For Hot Rolled Steel

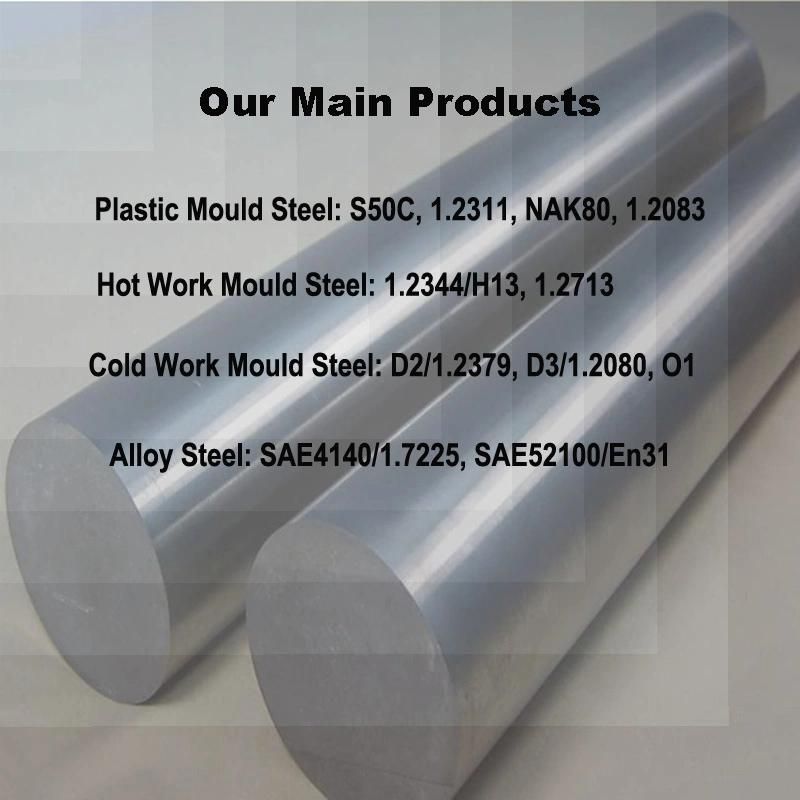

Guangzhou Changfeng Steel Co., Ltd.- Type:Alloy Steel Bar

- Standard:AISI, ASTM, GB, JIS, DIN, BS

- Technique:Hot Rolled

- Application:Tool Steel Bar, Die Steel Bar

- Surface Treatment:Black, Grinded, Machined

- Alloy:Alloy

Base Info

- Model NO.:1.3247, M42, SKH59, W2Mo9Cr4VCo8

- Special Use:Used for Cutters in Common Use

- Length:1000-6000mm

- Dimensions:Dia 6-400mm

- Grade:1.3247, M42, Skh59, W2mo9cr4vco8

- Annealed Hardness:255hbs

- Certificate:ISO , Mill Certificate

- Test:SGS , Ut 100% , Element Testing

- Payment:30% Deposit, Blance by L,C at Sight or T,T

- Delivery Quantity:Include MOQ

- Transport Package:Export Standard Packing or Customers′demand

- Specification:DIN JIS AISI GB

- Trademark:CF STEEL

- Origin:China

- HS Code:7228300000

- Production Capacity:1000t,Month

Description

Basic Info.

Model NO. 1.3247, M42, SKH59, W2Mo9Cr4VCo8 Special Use Used for Cutters in Common Use Length 1000-6000mm Dimensions Dia 6-400mm Grade 1.3247, M42, Skh59, W2mo9cr4vco8 Annealed Hardness 255hbs Certificate ISO / Mill Certificate Test SGS / Ut 100% / Element Testing Payment 30% Deposit, Blance by L/C at Sight or T/T Delivery Quantity Include MOQ Transport Package Export Standard Packing or Customers′demand Specification DIN JIS AISI GB Trademark CF STEEL Origin China HS Code 7228300000 Production Capacity 1000t/MonthProduct Description

1.3247/M42 High Speed Alloy Steel Bar For Hot Rolled SteelApplication:

Used for cutters in common use.

1) This for high speed steel, tungsten steel adaptable to make strong cutting use wear-resisting, resistance to impact a variety of tools, advanced punching die, screw die;

2) It need toughness and shape complex tools, milling cutter, drill, etc.

Feature:

1) Die steel for manufacturing strong cutting with wear-resistant, resistant to impact a variety of tools;

2) Specially for hard and hi-speed cutting;

Preheat temperature: 730-730 °C

Quenching temperature: 1190-1210 °C

Tempering temperature: Cold drawn, hardness 285 HBS,Cold drawn after annealing condition, hardness 277 HBS;

Heat treatment

Fire: isothermal annealing temperature is 800 ~ 880 °C, with 10 ~ 20 °C, the dHr furnace cooling to about 600 °C, hardness above HB269;

Chemical composition (%)

| C | Si | Mn | P | S | Cr | V | W | Mo | Co |

| 1.~1.15 | ≥0.65 | ≥0.40 | ≤0.030 | ≤0.030 | 3.50~4.50 | 0.95~1.35 | 1.15~1.85 | 9.0~10.0 | 7.50~8.50 |

Quenching methods: oil quenching, air cooling or salt bath quenching;

Delivery state:

forging parts produced with continuous casting and electro-slag re-melting process; rolled as annealed, bright and quenched/tempered steel bars.

Listed specifications are only typical grades; products of required specifications can be developed/produced per international, Chinese or industry standards, or based on agreements with customers.

Packing:

Export Standard Packing or Customers'demand;

Delivery:

For abundant stock, 15-20 days.

For customized products, 30-50 days.

Product pictures: