China Heat Treatment Alloy Steel Round Bar ASTM4140 42CrMo 40cr

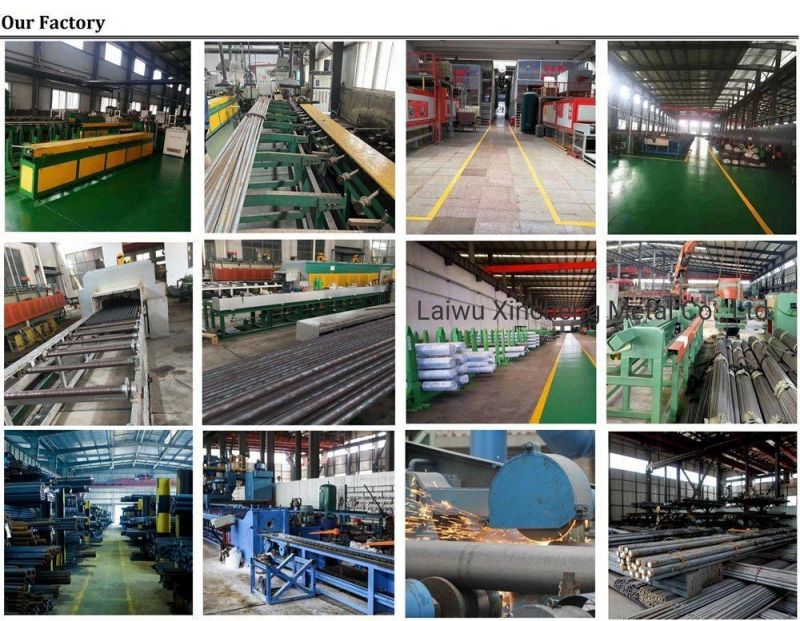

Laiwu Xincheng Metal Co., Ltd.- Type:Alloy Steel Bar

- Standard:AISI, ASTM, GB, JIS, DIN, BS

- Application:Structural Steel Bar, Tool Steel Bar, Die Steel Bar

- Surface Treatment:Polished

- Alloy:Alloy

- Special Use:Mold Steel

Base Info

- Model NO.:4140 STEEL

- Products:Q&T Steel Round Bars

- Grade:Scm440 4140

- Condition:Quenched and Tempered

- Size:10mm to 310mm

- Transport Package:Standard Export Packing

- Specification:M12-M100

- Trademark:Laiwu Xincheng

- Origin:China

- Production Capacity:3000tons,Month

Description

4.Heat Treatment of 42CrMo4 Steels

Annealing of 42CrMo4 Steels

- Heat steel 42CrMo4 forged steel slowly and thoroughly to 800-850°C;

- Cool slowly in the furnace to the temperature 480°;

- Complete annealing the steel in the air.

Quenched and Tempered (Q+T)

- Heat 42CrMo4 steel slowly to 880°C;

- Soak at this temperature then quench in oil;

- Temper as soon as 42CrMo4 steel reach room temperature (20°C);

- Heat uniformly to the suitable temperature of 560°C;

- Withdraw the 42CrMo4 material from the furnace and cool in the air.

42CrMo4 alloy steel is widely used for engineering steel purpose, such as: making various kinds of machinery, automobile, mining spare part, the gearwheel of the engine, the driving gear of supercharger, the connecting rob, the pinchock under the high pressure, parts for power train applications, cold formed fastener components, shafts, gears, drill collars for the oil exploration, etc.

6.Quality control:

1. Melting Process: EAF+LF+VD

2. Both ends cut by saw

3. Ratio of forging:minimum 3:1

4. Grain size of final product: according to ASTM E112 more than 5,preferred more than 8

5. Ultrasonic test: As per SEP1921 Class C/c or D/d

7.MOQ: 2tons

8.Payment term: FOB CIF CFR EXW and so on

9.Delivery time : 7 to 30 days after deposit received.