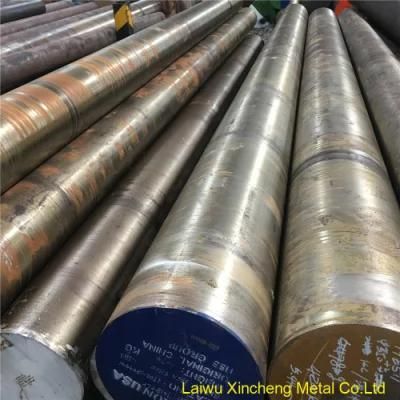

SAE 4140 En19 42CrMo4 Forged and Machined Steel Round Bars

Laiwu Xincheng Metal Co., Ltd.- Type:Alloy Steel Bar

- Standard:AISI, ASTM, GB, JIS, DIN, BS

- Technique:Forged

- Application:Structural Steel Bar, Die Steel Bar

- Surface Treatment:Black or Rough Machined

- Alloy:Alloy

Base Info

- Model NO.:AISI 4140 EN19 1.7225 42CRMO4

- Special Use:Mold Steel, Cold Heading Steel

- Ut Test:Sep1921- Class C,C,D,D

- PRO:Forged Steel Bars

- Grades:1020,1045,4130,4140,4150,8620,4340

- Transport Package:Standard Seaworthy

- Specification:200-1000mm

- Trademark:Laiwu Xincheng

- Origin:China

- HS Code:72284000

- Production Capacity:3000tons,Month

Description

0.15-0.30EN10083 1.7225 JIS G4105 SCM440 0.38-0.43 0.15-0.35 0.6-0.85 ≤ 0.035 ≤ 0.04 0.9-1.2 0.15-0.30 GB 3077 42CrMo 0.38-0.45 0.17-0.37 0.5-0.80 ≤ 0.035 ≤ 0.035 0.9-1.2 0.15-0.25 BS 970 EN19 0.35-0.45 0.15-0.35 0.5-0.80 ≤ 0.035 ≤ 0.035 0.9-1.5 0.2-0.40

7.4140 Forged Steel Application

42crmo4/4140 steel finds many applications as forgings for the aerospace,oil and gas,automotive, agricultural and defense industries etc.

Typical applications for 4140 steel uses include:forged gears,spindles,fixtures,jigs,collars,Axles,conveyor parts,crow bars,logging parts,shafts,sprockets,studs,pinions,pump shafts, rams, and ring gears etc

8.Quality control:

1. Melting Process: EAF/BOF+LF+VD resulting in ingots

2. Both ends cut by saw

3. Ratio of forging:minimum 3:1

4. Grain size of final product: according to ASTM E112 more than 5,preferred more than 8

5. Ultrasonic test: As per SEP1921 Class C/c or D/d

9.Heat treatment of 42crmo4/4140 Steel

Quenched and Tempered (+QT) of EN19 Steel

1. Heat 42crmo steel slowly to 840-875°C;

2. Soak at this temperature then quench in oil;

3. Temper as soon as 42crmo reach room temperature (20°C);

4. Heat uniformly to the suitable temperature of 560°C;

5. Withdraw the material from the furnace and cool in the air.

Annealing of 42crmo Alloy Steel

1. Heat the 42crmoslowly to 800-850°C and allow enough time.

2. Cool slowly in the furnace to 480°C followed by air cooling

10.MOQ: one piece per size/grade

11.Payment term: FOB CIF CFR EXW and so on

12.Delivery time : 7 to 30 days after deposit received.

7.4140 Forged Steel Application

42crmo4/4140 steel finds many applications as forgings for the aerospace,oil and gas,automotive, agricultural and defense industries etc.

Typical applications for 4140 steel uses include:forged gears,spindles,fixtures,jigs,collars,Axles,conveyor parts,crow bars,logging parts,shafts,sprockets,studs,pinions,pump shafts, rams, and ring gears etc

8.Quality control:

1. Melting Process: EAF/BOF+LF+VD resulting in ingots

2. Both ends cut by saw

3. Ratio of forging:minimum 3:1

4. Grain size of final product: according to ASTM E112 more than 5,preferred more than 8

5. Ultrasonic test: As per SEP1921 Class C/c or D/d

9.Heat treatment of 42crmo4/4140 Steel

Quenched and Tempered (+QT) of EN19 Steel

1. Heat 42crmo steel slowly to 840-875°C;

2. Soak at this temperature then quench in oil;

3. Temper as soon as 42crmo reach room temperature (20°C);

4. Heat uniformly to the suitable temperature of 560°C;

5. Withdraw the material from the furnace and cool in the air.

Annealing of 42crmo Alloy Steel

1. Heat the 42crmoslowly to 800-850°C and allow enough time.

2. Cool slowly in the furnace to 480°C followed by air cooling

10.MOQ: one piece per size/grade

11.Payment term: FOB CIF CFR EXW and so on

12.Delivery time : 7 to 30 days after deposit received.