-

Tianjin Good Quality Galvanized Steel Tube / Gi Steel Round Pipe

MaterialQ195 Q235 Q345OD20mm~706mmThickness1.0mm~17mmLength0.5m~12mMOQ10TonsInspection reportSGS/CCIC/BVTianjin Friend Steel Group with "TFCO" Brand has 5 subsidiary compainies include Tianjin Friend Steel Pipe Co.,Ltd.Tianjin Steel Galvanization Co.,Ltd.Tianjin Friend Metal Material Co.,L

-

Hot Dipped Galvanized Steel Pipe JIS Ss400 Ss490

MaterialQ195 Q235 Q345OD20mm~706mmThickness1.0mm~17mmLength0.5m~12mMOQ10TonsInspection reportSGS/CCIC/BVTianjin Friend Steel Group with "TFCO" Brand has 5 subsidiary compainies include Tianjin Friend Steel Pipe Co.,Ltd.Tianjin Steel Galvanization Co.,Ltd.Tianjin Friend Metal Material Co.,L

-

Stainless Steel 304L 316L Grade Steel Sheet

-

Alloy Steel Plate 1050/1055/S50c/S55c/1.1730 Hot Rolled Steel Plate

Plat /Flat BarsThickness:10-800mmSteel Condition:Hot Rolled & Hot ForgedAnneal:≤230HBSurface: Black surface/ Milling surfaceFabrication and Heat Treatment:Tempering:tool steels are tempered at 482-593°C (900 to 1100°F) for a Rockwell C hardness of 28 to 34.Annealing:Annealing takes pl

-

Stainless Steel 304 316 Grade Steel Sheet

-

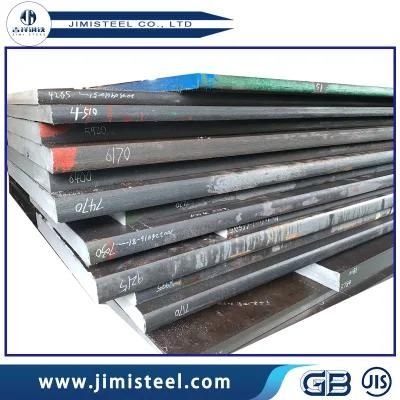

1.2738/P20+Ni/718 Alloy Tool Steel Plate for Plastic Mould

1.2738 die steel is a kind of die steel produced according to German DIN standard. It has relatively superior mechanical properties and good machinability in similar grades of steel. It is mainly used in the processing and production of hot working dies, among which plastic dies are the most widely

-

20-800mm*2200*6000 Carbon Steel 34cr2ni2mo Steel Alloy Structural Steel Flat Bar

34cr2ni2mo structural steel is characterized by high strength, toughness, good hardenability and stability against overheating, but it has high white spot sensitivity and temper brittleness. The weldability is poor. It needs high temperature preheating before welding and stress relief after welding.

-

12cr1MOV/35CrMo/30Cr2Ni2Mo/34cr2ni2mo/25cr2ni4MOV Structrual Alloy Steel Bar Steel Plate

1. Normalizing: 920 ± 10 ºC for 7-8h air cooling2. Tempering: 650 ± 10 ºC for 7-8h air cooling2.Heat Treatment Process1. Normalizing: 920 ± 10 ºC for 7-8h air cooling2. Tempering: 650 ± 10 ºC for 7-8h air cooling3.ApplicationMolds for corrosive plastic