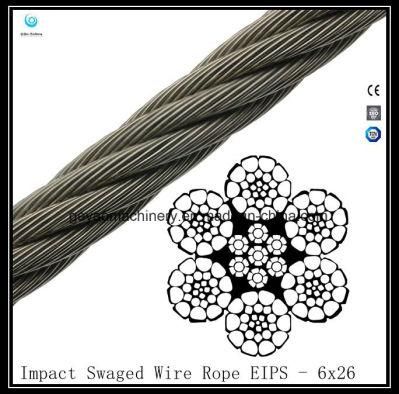

6X26 Iwrc Impact Swaged Wire Rope Eips

Chongqing Geyo Machinery Co., Ltd.- Certification:ISO, CE, ISO, CE, TUV

- Surface:Galvanized,Ungalvanized,Stainless Steel, Smooth

- Technique:Galvanized, Ungalvanized

- Application:Rope, Packaging, Netting, Manufacturing, Fencing, Rope, Construction

- Alloy or Not:Non-alloy, Non-Alloy

- Standard:BS, JIS, GB, ASTM, DIN, AISI, BS, JIS, GB, ASTM, DIN, AISI

Base Info

- Structure:6*26 Iwrc

- Tensile Strength:1570-1960MPa

- Diameter:as Customer′s Request

- Steel Grade:High Carbon Wire Rod

- Transport Package:in Wooden Reel

- Specification:0.2-52mm

- Trademark:GEYO

- Origin:China

- HS Code:7312100000

- Production Capacity:10000meters,Month

Description

Basic Info.

Structure 6*26 Iwrc Tensile Strength 1570-1960MPa Diameter as Customer′s Request Steel Grade High Carbon Wire Rod Transport Package in Wooden Reel Specification 0.2-52mm Trademark GEYO Origin China HS Code 7312100000 Production Capacity 10000meters/MonthProduct Description

6x26 IWRC Impact Swaged Wire Rope EIPS

Features

1.Crush Resistant, Excellent Tensile Strength

2.Used with Cranes, Dredging, Excavating, Logging, Oil, and Marine

3.Winch Lines, Choker Ropes, Hoist Ropes, Trolley Lines, and Boom Lines

Brief Description

1.Made of Extra Improved Plowed Steel (EIPS).

2.6 x 26 impact swaged wire rope construction also offers excellent crush resistance and tensile strength so this steel cable is ideal for winch lines, choker ropes, hoist ropes, trolley lines, and boom lines.

Specification

| Diameter | Steel Grade | Core | Class | Material | Quantity | Weight | Break Strength |

| 5/8" | Extra Improved Plowed Steel (EIPS) | IWRC | 6x26 | Bright Steel | Ordered in lineal feet | 0.78lbs | 58400lbs |

| 3/4" | Extra Improved Plowed Steel (EIPS) | IWRC | 6x26 | Bright Steel | Ordered in lineal feet | 1.25lbs | 82400lbs |

| 7/8" | Extra Improved Plowed Steel (EIPS) | IWRC | 6x26 | Bright Steel | Ordered in lineal feet | 1.54lbs | 110000lbs |

| 1" | Extra Improved Plowed Steel (EIPS) | IWRC | 6x26 | Bright Steel | Ordered in lineal feet | 2.00lbs | 144000lbs |

An impact swaged 6 x 26 wire rope offers greater strength over a similarly-sized 6 x 26 wire rope, and also offers better resistance to drum crushing, scrubbing and general overall wear. Impact swaging is a special process that creates a compacted section with great surface area on the outer wires and minimum voids. Additionally, special wire chemistry make-up within the outside strands of this swaged cable add an extra measure of durability for heightened performance.

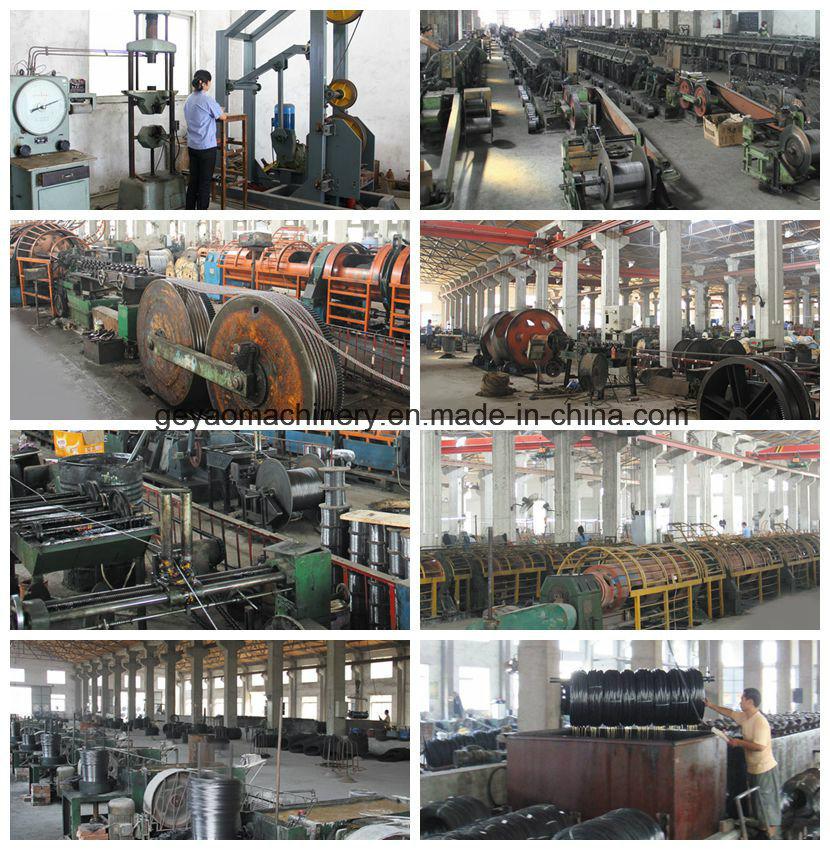

PRODUCTION

PRODUCTION FLOW AND MEASURING METHOD OF WIRE ROPE

STORAGE

TRANSPORTATION OR LOADING

For enquiry,please kindly advise below information to us.

1.Application: For which rope will be used.

2.Size: Diameter of the rope in millimeter or inches.

3.Construction: Number of strands, number of wires per strand and type of strand construction.

4.Type of Core: Fiber core(FC), independent wire rope core(IWRC) or independent wire strand core(IWSC).

5.Lay: Right regular lay,left regular lay,right lang lay,left lang lay.

6.Lubrication:Preformed or not.

7.Material: Bright(un-galvanized),galvanized or stainless steel

8.Grade of wire: Tensile strength of wires

9.Breaking Load: Minium or calculated breaking load in tones or pounds.

10.Length: Length of wire rope.

11.Packing: In coils wrapped with oil paper and hessian(orp.p)cloth, or on wooden reels.

12.Quantity: By number of coils or reels,by length or weight

13.Specification: Any recognized specification, if necessary.

14.Certification: Mill sheet and/or a third party's inspection,if necessary.

15.Remarks: Shipping marks and any other special requirements.