-

Cr12MOV 1.2379 D2 SKD11 Cold Work Tool Steel Bar

510-54060-64Features1. High wear resistance2. High compressive strength3. Good dimensional stability4. Good processability5. Good toughness6. Excellent resistance to temper softeningApplications1. Thin sheet with a thickness of not more than 2mm, high-efficiency blanking die, punching die and stampi

-

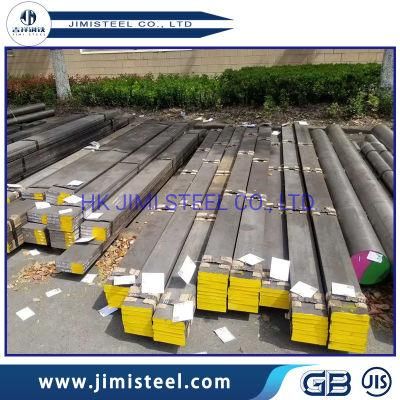

Cold Work Tool Steel Flat Bar Assab88 (K340, DC53, A8)

SizeRoundDia 6-1200mmPlate/Flat/BlockThickness6mm-500mmWidth20mm-1000mmHeat treatmentNormalized ;Annealed ;Quenched ;TemperedSurface conditionBlack; Peeled; Polished; Machined; Grinded; Turned; MilledDelivery conditionForged; Hot rolled; Cold drawnTestTensile strength, Yield strength, elongation, ar

-

China Steel A36 Steel Flat Bar Size

FlatBarWidth(mm)Thickness(mm)Length(m)TheoreticalWeight(kg/m)202.06/9/120.31202.56/9/120.39202.756/9/120.43252.56/9/120.49253.756/9/120.74302&peri

-

Good Quality 40crmnmos8-6 1.2312 Plastic Mould Steel (PA80)

Basic Info. Model NO. P80A

-

S45c C45 1.1191 080m40 1045 Hot Forged Rolled Flat Steel Bar

SizeRoundDia 6-1200mmPlate/Flat/BlockThickness6mm-500mmWidth20mm-1000mmHeat treatmentNormalized ;Annealed ;Quenched ;TemperedSurface conditionBlack; Peeled; Polished; Machined; Grinded; Turned; MilledDelivery conditionForged; Hot rolled; Cold drawnTestTensile strength, Yield strength, elongation, ar

-

Ground Tool Die Steel 1.2083 Plastic Mold Steel Bar 1.2083 Milling Surface

Product ParameterGrade Steel1.2083 4Cr13 420Chemical CompositionC:0.35-0.45 Si:≤1.00 Mn:≤1.00 Cr:12.5-14.5 Ni:≤1.00ConditionHot Rolled; Anneal≤217HB.StandardAISI GB JIS DINOrginalCHINATechnological ProcessCUTTING STEEL MATERIAL- Flate/ Round (Vertical Cutting/ Horizontal Cutting machine)

-

1.2311 1.2312 1.2738 NAK80 1.2083 1.2316 Plastic Mold Steel Sheet

Elastic ModulusHBMpaKSIMpaKSI%Z%GPAKSI3008261209931451759205297456. Hardness:33-37HRCNAK80 P21Plastic Mould SteelNAK80 is apre-hardened plastic mold steel.Factory hardness can reach HRC37-43.Have agood polishing performance and carving, good electrical discharge.Use in the mirror polishing mold, aut

-

HeatTreatmentAnnealing:1,800-850oC, slow cooling2,SpheroidizingQuenching:940-960oC, air coolingTempering:180-220oC, air coolingHRc=60-64 510-520oC, air cooingHRc=57-60SupplyStatesSpheroidizing HB≤2305.Feature:1.Good processing, heat treatment size stability.2. Excellent machinability.3. Excellent

-

Tool and Die Steel 1.2311 Steel Plate P20 3Cr2Mo Plastic Tool Steel

Feature:1.Vacuum degassing refining processing steel purity, suitable for polishing or etch processing plastic mold.2. In pre-harden state delivery, no need for heat treatment can be directly used for mold processing, shorten the construction.3. After heat treatment machining and polishing performan