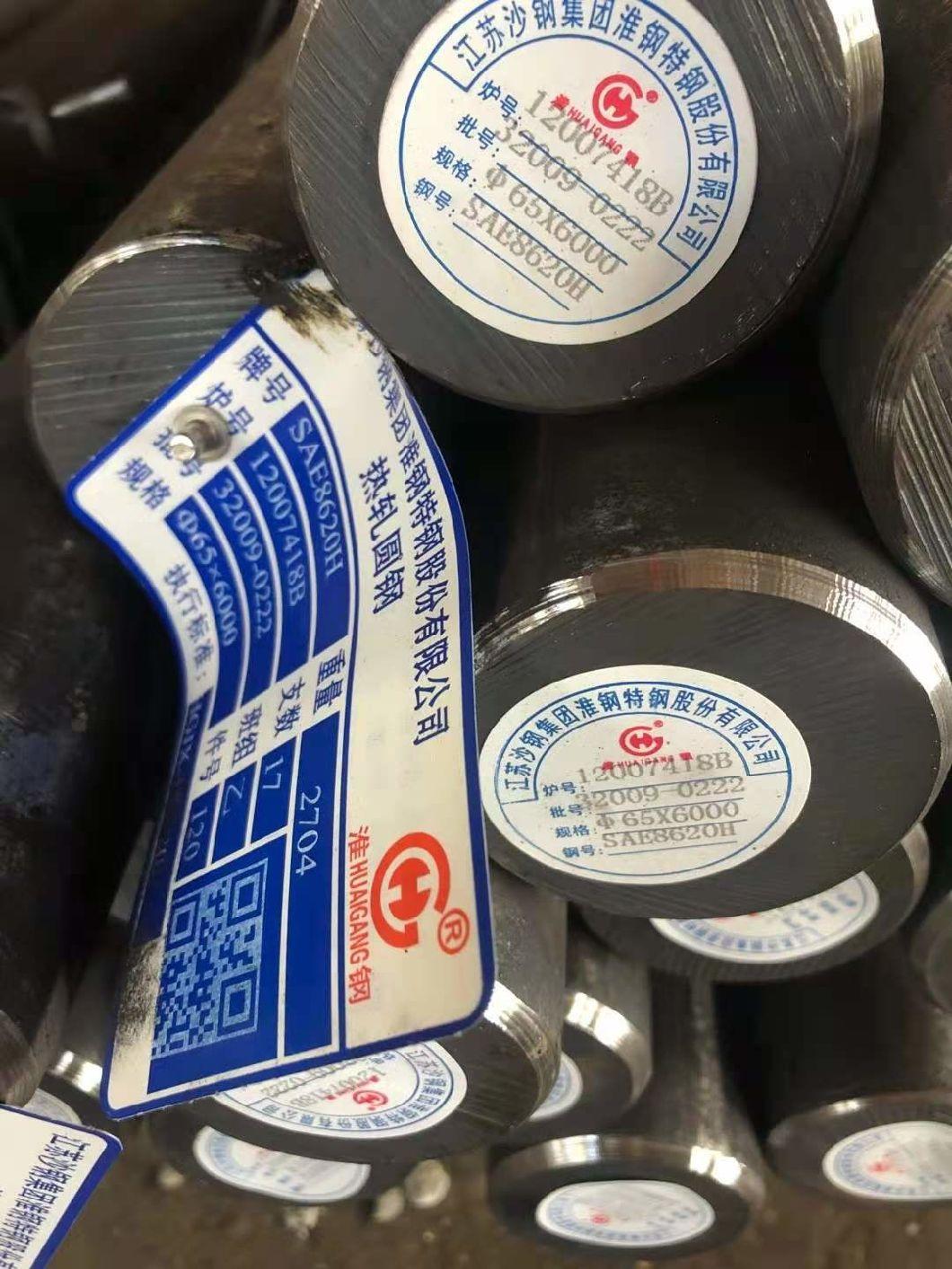

DIN10278 DIN1.6523 Material Cold Stretcted a+C AISI 8620 Steel Rectangular Bar

Wuxi City Ge Ming Sheng Steel Trading Co., Ltd- Transport Package:Wooden Box

- Alloy:Alloy

- Surface Treatment:Polished

- Technique:Hot Rolled

- Standard:ASTM

- Specification:6*6-300*300mm

Base Info

- Production Capacity:500tons

- HS Code:7219340000

- Model NO.:SAE8620

Description

Forging Machinability Welding Cold Working Forms manufactured: Please see the Dimensional Sales Program. Disclaimer Chemical Composition Mechanical Properties General Applications Widely used for stransmission system,motor of tractor and middle-small auto. Alternative 12CrNi3 to make higher class carburization and cyanide carburizing parts such as oil drilling,claws and cone for mining. It is commonly used for carburized gears, pinions, shafts, bearings, piston rings, ring gears, crankshafts, etc. Stock Size Our steel materials are in different sizes and conditions specially catered to our customers' needs. They come in round bars, flat bars, plates and blocks. The conditions of the materials vary from pre-hardened, hot rolled,annealed, quenched and tempered to surface conditions such as black, pre-machined,griding and polish. Why choose us? Quality Assurance from government owned steel mills we meticulously source materials only from steel manufacturers to ensure consistency in providing the finest quality steel products for our customers. Being in the competitive market today, we clearly understand that customers are looking for products that are not only best in class but also affordably priced. We are confident that we are able to ful fil these two equally vital aspects -our customers' continuous support over the past two decades is the most heartfelt recognition to us. Speedy and Timely Delivery Knowing that delivering goods to customers' hands on time is as important as providing quality goods, we treat every business transaction as a priority. Be it a raw material or a finished material with machining or heat treatment, every effort will be made to get your purchase order to you in the shortest lead time. Quality Commitment In order to realise competitive products to fulfil our customers' demands and quality considerations, our integrated quality and work management system is continuously being improved and developed further. We document this for our customers by having our quality management system certified in accordance with ISO 9001. This measure is accompanied by audits and recertification's on a regularly prescribed basis. Our service We provide quality special steel for all industries. Orders of any size, any length, ship fast We carry a unique inventory of specialty special steel Provide related value-adding services : metal cutting, sizing, machining (blanking, milling, grinding), and heat treatment. Sawing for small or large quantities, sawing-to-size. Excellent customer servicemm 1.5 3 5 7 9 11 13 15 20 25 30 35 40 H max. 49 48 45 42 36 33 31 30 27 25 24 24 23 H min. 41 37 31 25 22 20 - - - - - - - HH max. 49 48 45 42 36 33 31 30 27 25 24 24 22 HH min. 44 41 36 31 27 24 22 21 - - - - - HL max. 46 44 40 36 31 29 27 26 23 21 20 20 - HL min. 41 37 31 25 22 20 - - - - - - -

Hot forming temperature: 1150-850oC.

Machining is done prior to carburizing to within as close a tolerance as possible. Finish machining, after heat treatment and/or carburizing, should be at a minimum so as not to impair the hardened case of the part. Machining may be done by conventional means prior to heat treatment - after carburizing machining is usually limited to grinding.

The alloy may be welded by conventional methods, usually gas or arc welding. Preheating at 200oC is beneficial and subsequent heating after welding is recommended - consult the approved weld procedure for the method used.

The alloy may be cold worked in the annealed condition by conventional methods. Cold working, as with machining, should be done to as close a tolerance as possible before heat treatment or carburizing.

The information and data presented herein are typical or average values and are not a guarantee of maximum or minimum values. Applications specifically suggested for material described herein are made solely for the purpose of illustration to enable the reader to make his own evaluation and are not intended as warranties, either express or implied, of fitness for these or other puposes. There is no representation that the recipient of this literature will receive updated editions as the become available. Grades C Si Mn P S Cr Mo Cu Ni 20CrNiMo 0.17-0.23 0.17-0.37 0.6-.95 ≤0.035 ≤0.035 0.4-.7 0.20~0.30 ≤0.30 / Queching Temperature(ºC):850;Cold Media:oil Tempering(ºC):200;Cold Media:air Tensile strength σb (MPa):≥980(100) Yield strengthσs (MPa):≥785(80) Elongationδ5 (%):≥9 Reduction of area ψ (%):≥40 Akv (J):≥47 round bar Diameter 12-380mm Sizes and Conditions