Tin Coated Dr8 Dr9 2.8/2.8 SPTE SPCC Tinplate Coil

Qingdao Quanlong Metal Materials Co., Ltd.- Certification:ISO, RoHS, IBR

- Standard:ASTM, JIS, GB, AISI, DIN, BS

- Warranty:Yes

- After-sales Service:Yes

- Surface Treatment:Coated

- Technique:Cold Rolled

Base Info

- MOQ:5 Tons

- Payment:T,T

- Delivery Time:15-20 Work Days

- Coil Weight:2-10mt

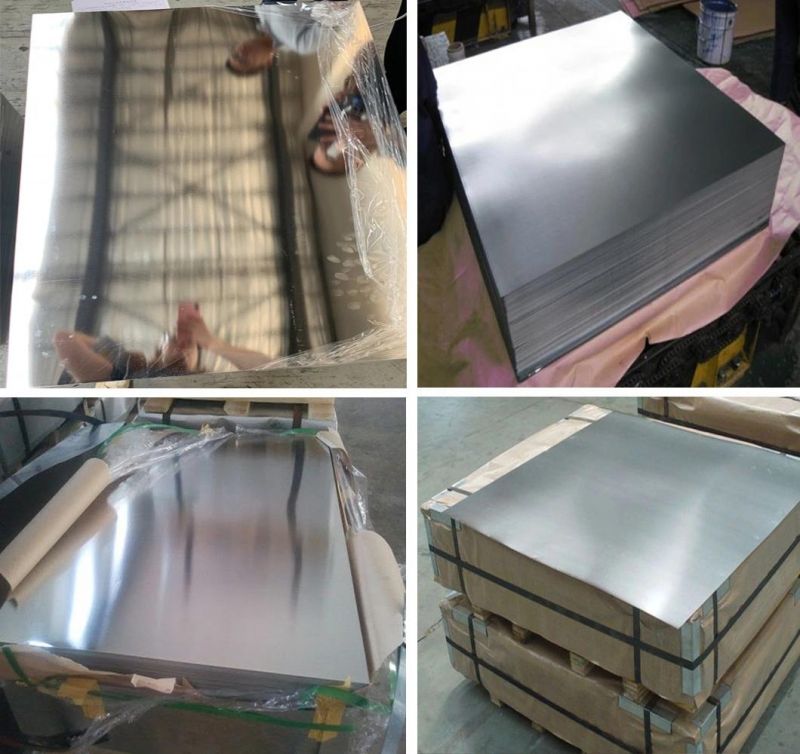

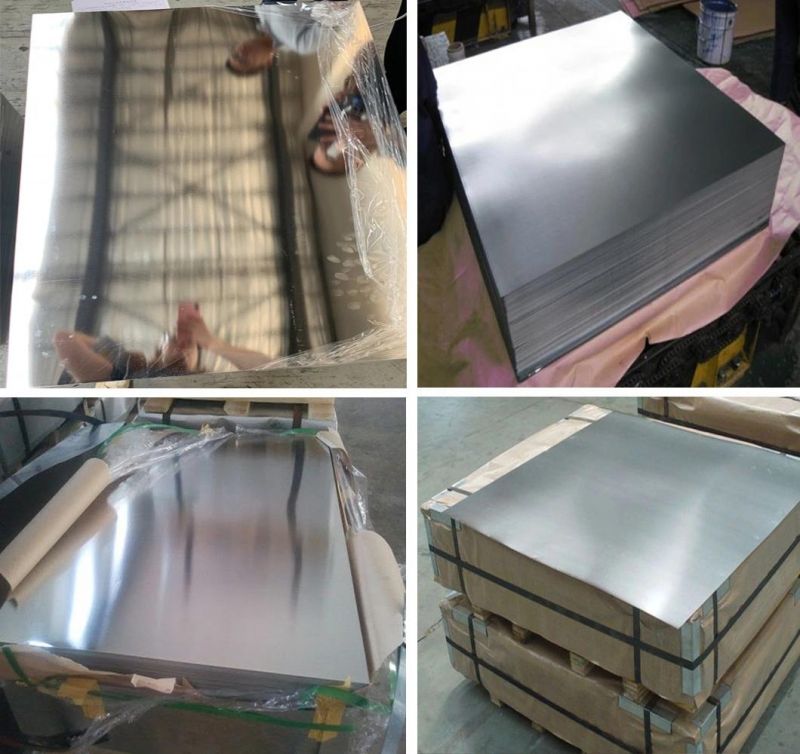

- Packing Standard:Anti-Rust Paper+Galvanized Steel Sheet

- Form:Coils, Plain Sheet

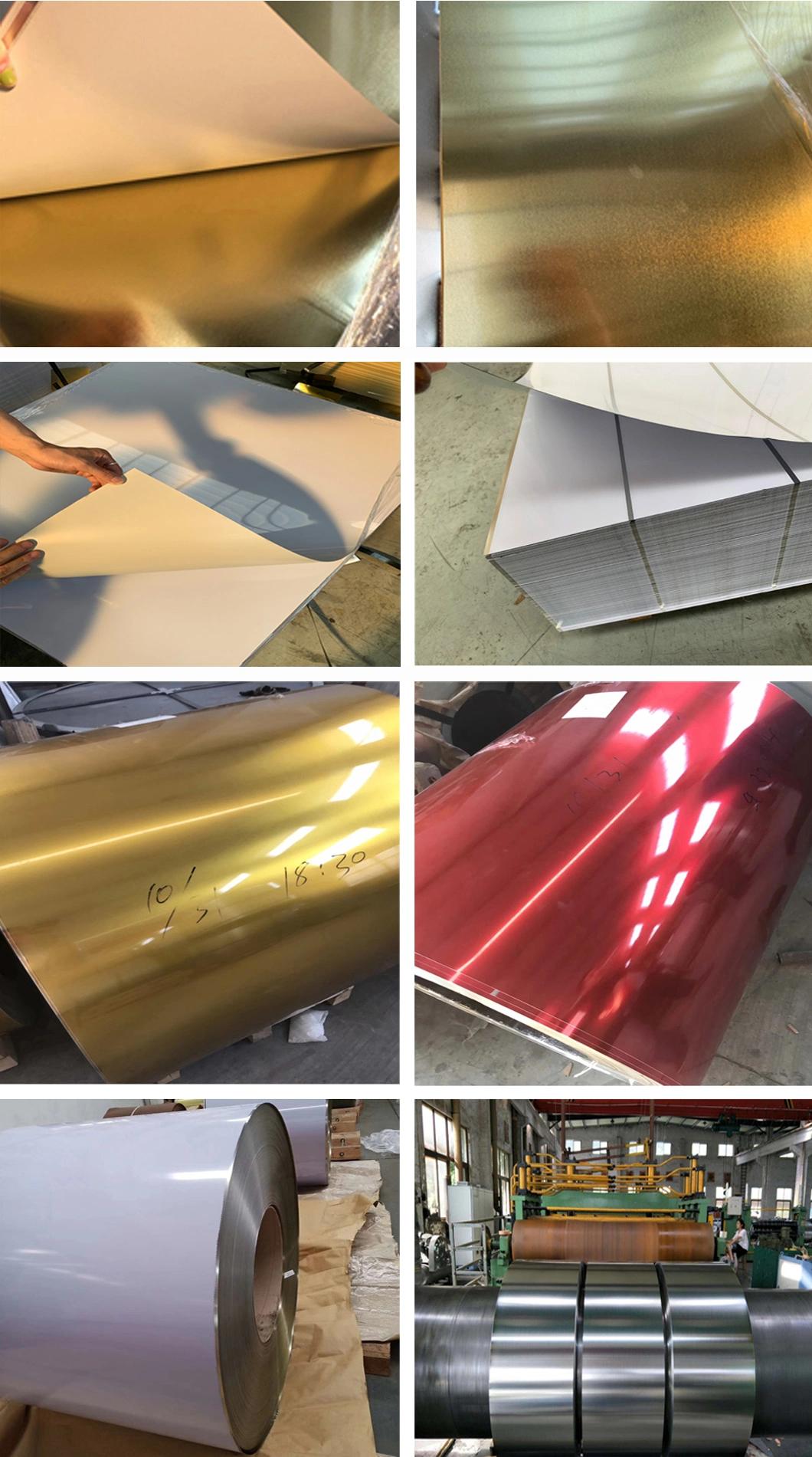

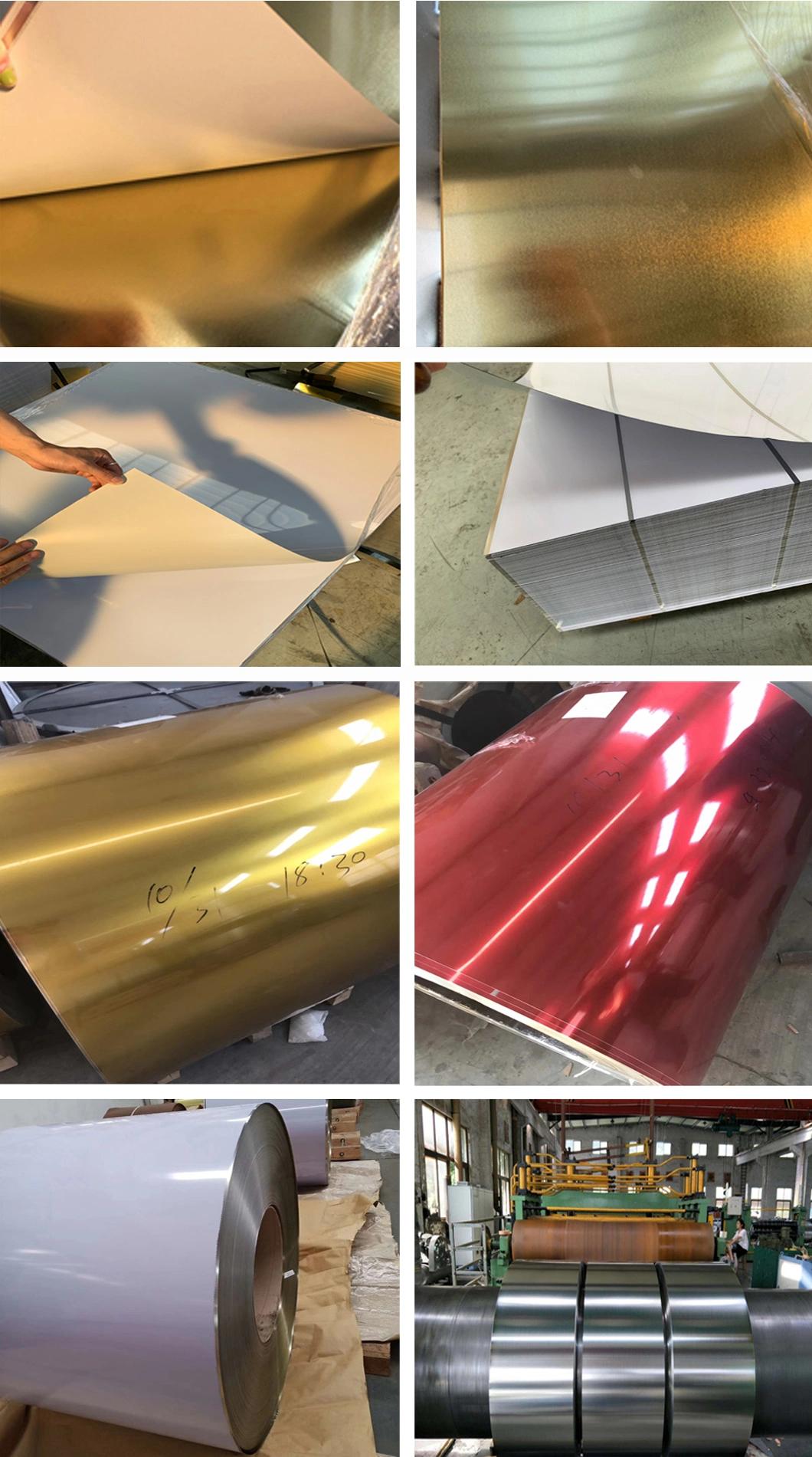

- Surface:Stone Finish ,Bright Finish , Matte Finish

- Coating:2.8,2.8,2.8,5.6,5.6,5.6

- Temper:T2 to T5 , Dr 8 and Dr 9

- Width:300~1250mm

- Thickness:0.135~0.70mm

- Base Metal:Mr,SPCC,SPTE

- Product:Tin Coated Dr8 Dr9 2.8,2.8 SPTE SPCC Tinplate Coil

- Stock:Not Stock

- Edge:Mill

- Application:Mainly for Packaging

- Model NO.:Tin Coated DR8 DR9 2.8,2.8 SPTE SPCC Tinplate Coil

- Delivery Term:Fob, CIF...

- Service:Can Be Customized

- Transport Package:Standard Export Packing, Paper+Film

- Specification:CE, RoHS, SGS, BV.

- Trademark:Quanlong

- Origin:China Mainland

- HS Code:721012000

- Production Capacity:1100000

Description

Overview

Tinplate SpecificationCommodity Tinplate Standard GB2520-2000,JISG3303-2002and DINEN10202-2001 Material SPCC/MR/Q195/S08Al/SPHC~SPHD/SPTE Thickness 0.135-0.7mm (tolerance -/+0.01 mm) Width

300~1250mm (Tolerance: 0~3mm) or as per customers' requires Cutting Length

400~1250mm (Tolerance: 0~3mm) or as per customers' requires Annealing BA & CA Temper T1 T2 T3 T4 T5 DR8 DR9 BA and CA both Tin Coating 1.1/1.1 2.8/2.8 5.6/5.6 Or as per customers' requires Surface finish Bright, Stone, Silver, Matt Coil Diameter ID 420/ 508/610mm, OD from 1,000 to 1,250m Coil Weight 3~10 MT Package

Seaworthy Standard with wooden pallet, corner protected. by sheet or coils according customer's requires. Product line BA furnace line: LOI company

CA line: SMS Applications Metal package usage like paint, chemical can,aerosol can and different food can production, Also battery,electric cable and other industries Type Designation of tin coating weight Min.average tin coating weight(g/m2) Former Coating Designation Equal tin coating 1.4/1.4 1.2/1.2 #15 2.2/2.2 2.0/2.0 #20 2.8/2.8 2.45/2.45 #25 5.6/5.6 5.05/5.05 #50 8.4/8.4 7.55/7.55 #75 11.2/11.2 10.1/10.1 #100 Differentially Coating 1.4/2.8 1.2/2.45 #15/25 2.2/2.8 2.2/2.45 #20/25 2.8/5.6 2.45/5.05 #25/50 2.8/8.4 2.45/7.55 #25/75 2.8/11.2 2.45/10.1 #25/100 5.6/8.4 5.05/7.55 #50/75 5.6/11.2 5.05/10.1 #50/100 8.4/11.2 7.55/10.1 #75/100 Surface Finish Surface Finish Nominal surface roughness

(um Ra) Characteristic Bright Finish ≤0.35 Glazed surface obtained after melting treatment of electrotinned smooth raw material strip with extremely fine rubstone fingerure by processing Stone Finish 0.25~0.60 Glazed surface obtained after melting treatment of electrotinned smooth raw material stripfeaturing certain rubstone figures Silver Finish 0.50~1.00 Galzed surface obtained after melting treatment of electrotinned smooth raw material strip with rough matt surface Matte Finish 0.8~2.50 Matt surface of general matt raw material strip without melting treatment

Printing

Printing Usage

Usage Packaging & Shipping

Packaging & Shipping Stock

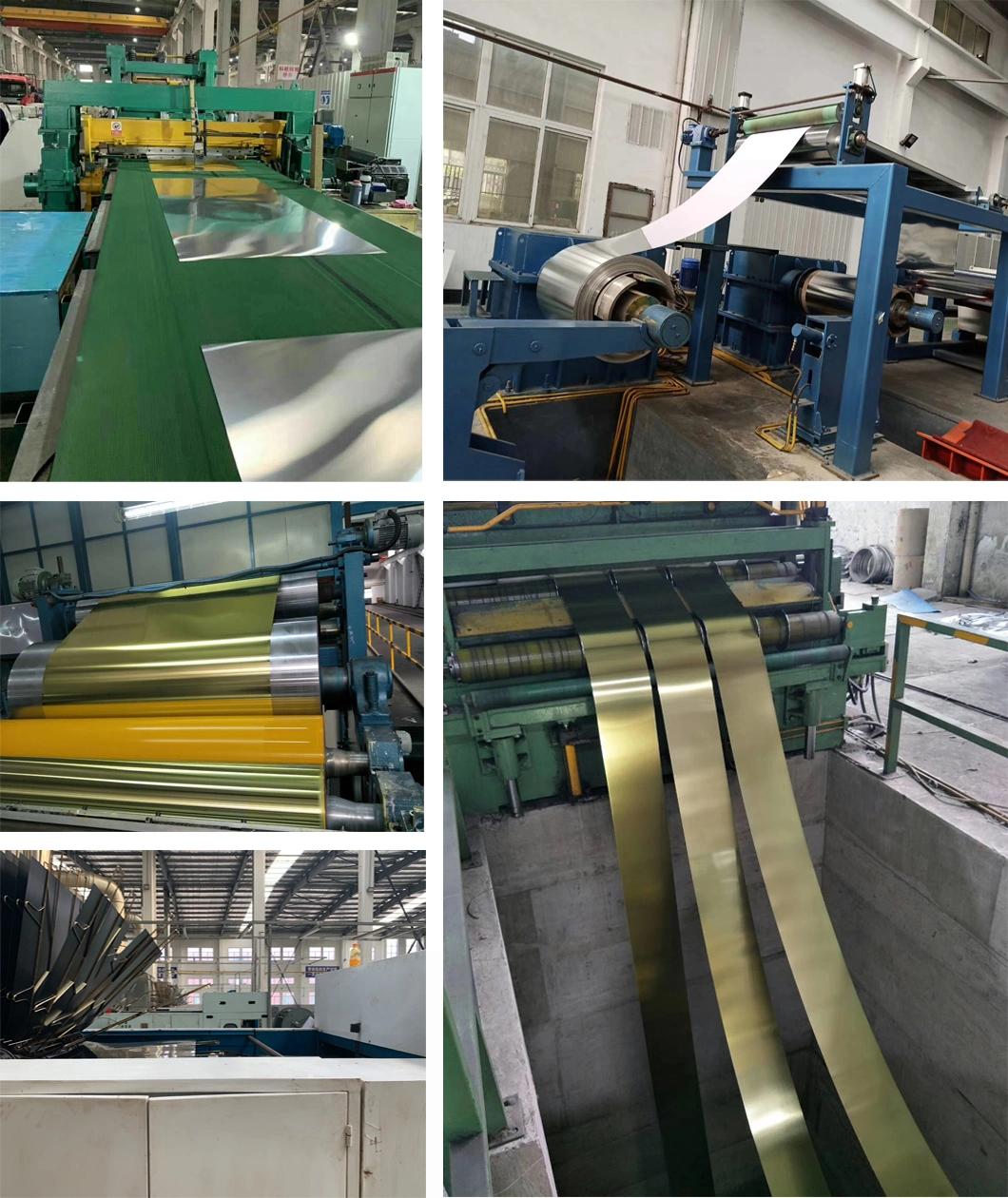

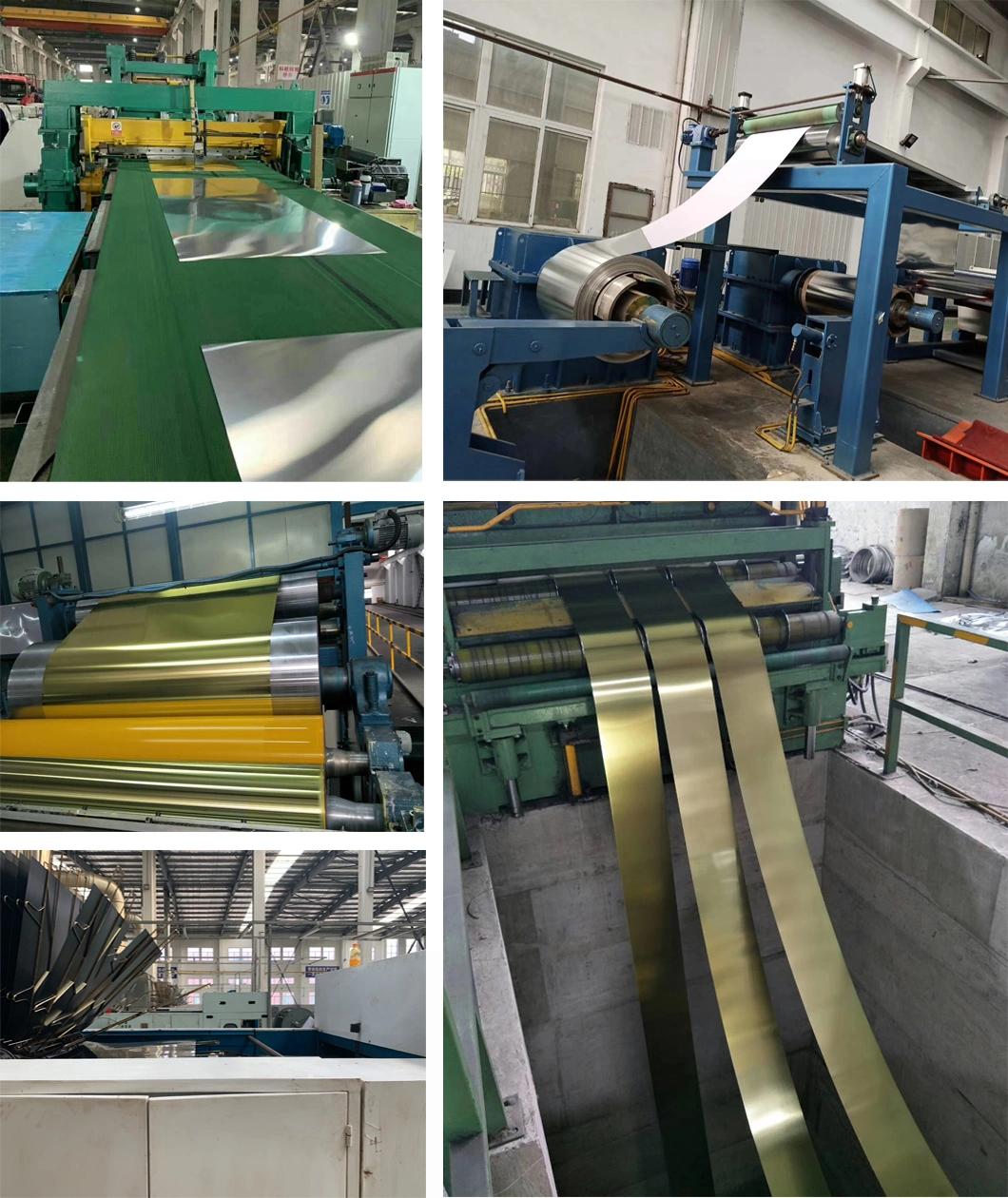

Stock Production Process

Production Process

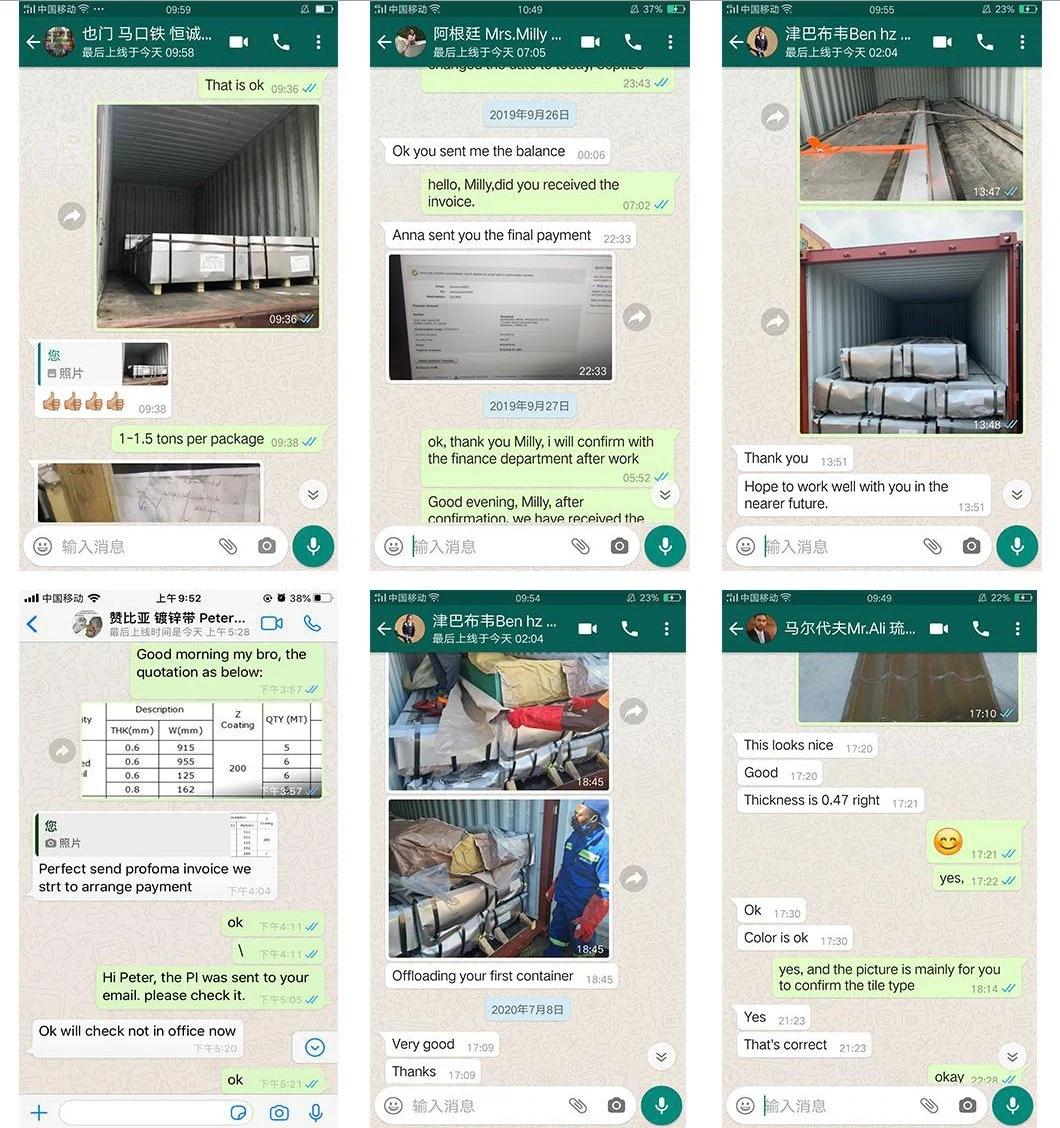

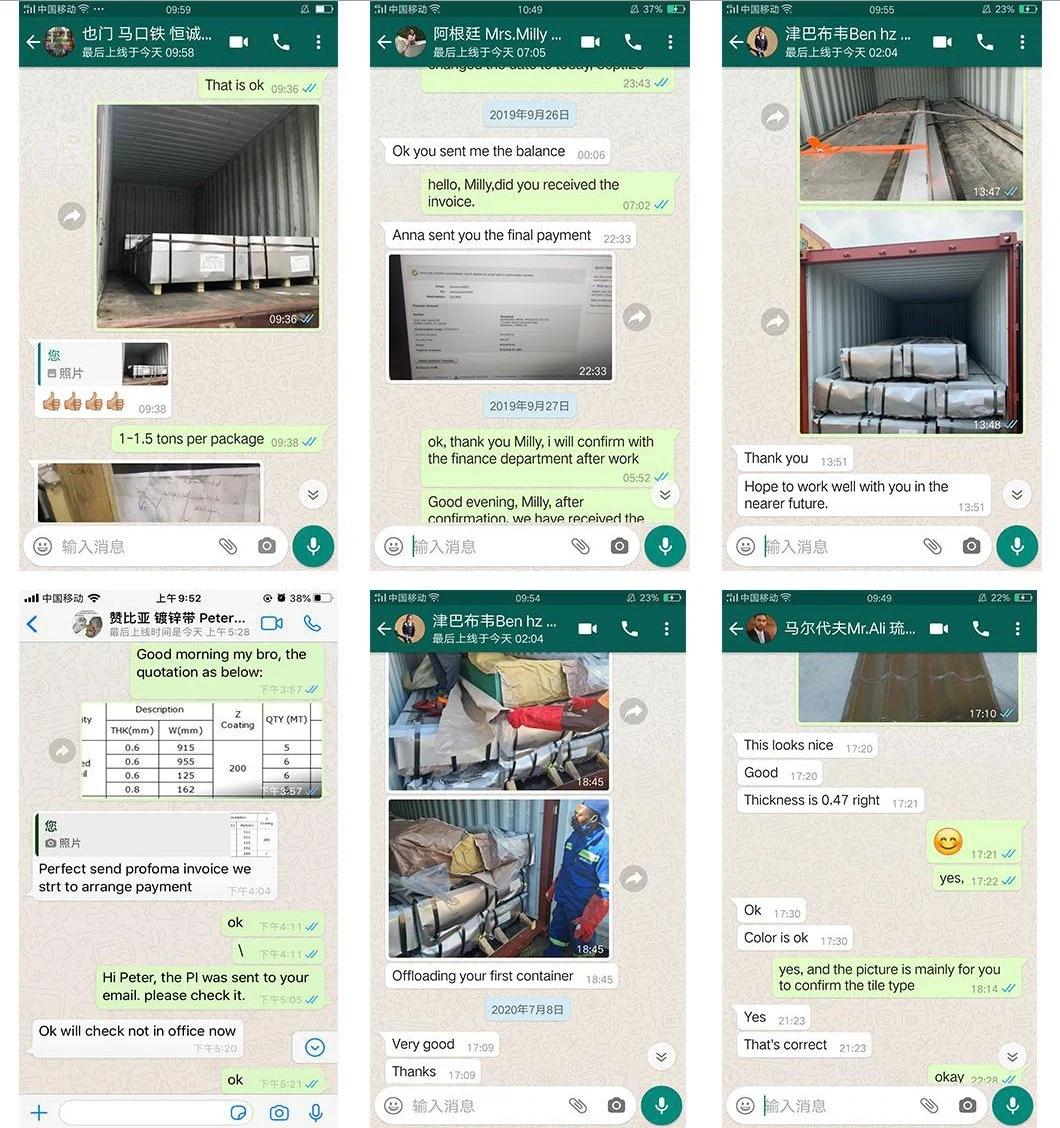

Customer Feedback

Customer Feedback

Certifications

Certifications

CA line: SMS

(um Ra)

Printing

Printing

Usage

Usage

Packaging & Shipping

Packaging & Shipping

Stock

Stock

Production Process

Production Process Customer Feedback

Customer Feedback

Certifications

Certifications