Titanium Beta 21s Uns R58210 Alloy Sheet

Shandong Zayi Steel Co., Ltd- Type:Alloy Bar

- Standard:ASTM, AISI, GB, JIS, DIN

- Grade:Hastelloy

- Certification:ISO, RoHS, IBR, AISI, ASTM, GB, EN, DIN, JIS

- Shape:Round

- Technique:Hot Rolled

Base Info

- Model NO.:R58210 sheet

- Surface Treatment:Bright

- Length:3m

- Material:R58210

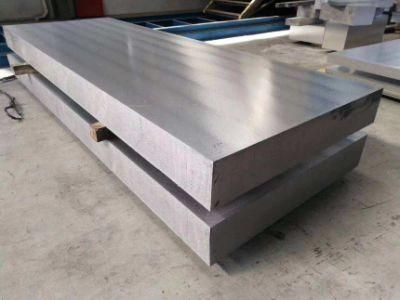

- Commodity Name:Titanium Plate

- Alloy or Not:Alloy

- Transport Package:Export Standard Packing

- Specification:5-200mm

- Trademark:Zayi

- Origin:China

- HS Code:7228309000

- Production Capacity:5000tons,Month

Description

Basic Info.

Model NO. R58210 sheet Surface Treatment Bright Length 3m Material R58210 Commodity Name Titanium Plate Alloy or Not Alloy Transport Package Export Standard Packing Specification 5-200mm Trademark Zayi Origin China HS Code 7228309000 Production Capacity 5000tons/MonthProduct Description

Product name:Titanium Beta 21S UNS R58210 alloy sheetTitanium Beta 21 S (Timetal 21S) is one of the beta titanium alloys which was developed as an oxidation-resistant aerospace material and as a matrix for metal-matrix composites. Titanium Beta 21 S (Grade 21) offers the good formability and weldability of a beta alloy, but with greatly improved oxidation resistance and creep strength. The composition of Beta 21S is Ti-15Mo-2.7Nb-3Al-0.2Si, designed to improve corrosion resistance with molybdenum and niobium working together to raise corrosion resistance to very high levels. Beta-titanium alloys show a reduced Young's modulus compared to pure titanium or Ti-6Al-4V, and can be composed completely from biocompatible elements making it a great choice for some medical applications.

Beta Titanium has strength & modulus of elasticity ratios almost twice those of austenitic stainless steel, larger elastic deflections in springs, and reduced force per unit displacement 2.2 times below those of stainless steel appliances.

Grade 21 Titanium has one of the lowest hydrogen uptake efficiency levels of any titanium alloy. It combines high strength, high corrosion resistance, and fracture toughness making it an ideal candidate for orthopedic implants, deep sour oil wells, geothermal brine wells, aerospace honeycomb, aerospace fasteners, and aerospace engine applications.

COMMON APPLICATIONS FOR TITANIUM GRADE 21

- High resistance to aircraft hydraulic fluids

- Used in warm airframes or engine structures

- Structural Honeycombs

- Fasteners

- metal matrix composites

- welded and seamless tubing

CHEMICAL COMPOSITION OF TITANIUM BETA 21S

| Element | Min | Max |

| Titanium | Balance | Balance |

| Molybdenum | 14.0 | 16.0 |

| Niobium | 2.4 | 3.2 |

| Aluminum | 2.5 | 3.5 |

| Silicon | 0.15 | 0.25 |

| Iron | 0.40 | 0.40 |

| Oxygen | 0.11 | 0.17 |

| Carbon | 0.05 | 0.05 |

| Nitrogen | 0.05 | 0.05 |

| Hydrogen | 0.015 | 0.015 |

| Residuals (each) | 0.10 | 0.10 |

| Residuals (total) | 0.40 | 0.40 |

COMMON TITANIUM GRADE NAMES

| Name | Code | Description 1 | Description 2 | ASTM | AMS | UNS |

| Titanium 21S | TI21S | Metastable beta alloy | Timetal 21S | R58210 |

PHYSICAL PROPERTIES OF TITANIUM 21S

Density: 0.178 lbs/in3, 4.94 g/cm3

Mean Coefficient of Thermal Expansion: in/in/° F (mm/m/° C):

70 - 212 °F (20 - 100 ° C) 3.93 x 10-5 (7.07)

Thermal Conductivity: BTU-in/h-ft-° F (W/m-° K):

70 ° F (21 ° C): 52.7 (7.6)

Modulus of Elasticity: ksi (MPa)

10.5 - 12 x 103 (72 - 85 x 103) in tension

Melting Point: 3034 °F (1668 °C)

Production Method:

Some Detail:

FAQ:

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

To learn more information,welcome to contact us.