Prepainted/Regular Spangles/Sgc340 Sgc440/Galvanized/Zinc Coated/Galvalume/Corrugated/Roofing Sheet/Aluminium/Cold Rolled/Roll/Steel/PPGL/Gl/Al/Gi/Coil/Coil

Shanghai Huagang Steel Co., Ltd.- Certification:ISO, RoHS, IBR

- Standard:ASTM, JIS, GB, AISI, DIN, BS

- Warranty:Supported

- After-sales Service:Supported

- Surface Treatment:Galvanized

- Technique:Hot Rolled

Base Info

- Model No.:Dx51d Dx52D Dx53D DC51D DC52D DC53D SGCC Sgcd Sgce

- Width:1000-1500mm or Customer Production

- Length:2000-6000mm or Customer Production

- Edges:Mill Edge, Slit Edge

- Technics:Hot Dipped, Hot Rolled, Cold Rolled

- Delivery Time:5-10 Days

- MOQ:1 Ton

- Material:Galvanized Steel

- Hardness:Soft,MID Hard,Full Hard

- Zinc Layer Thickness:Z10-Z600

- Applications:1%

- Sheet Thickness:0.1-5mm, or as Required

- Shape:Flat Sheet,Corrugated Sheet,Pipe,Coil

- Stock:Stock

- Edge:Slit edge

- Application:Building Material

- Model NO.:SGC340 SGC440

- Production Time:5-7 Workdays

- Delivery Term:Fob, CIF, CFR,EXW

- Transport Package:Marine Standard Packing

- Specification:4x8ft, 5x10ft, as required

- Trademark:HGS

- Origin:Shanghai

- HS Code:7210490000

- Production Capacity:50000pieces,Year

Description

Basic Info.

Model NO. SGC340 SGC440 Application Building Material Edge Slit edge Stock Stock Shape Flat Sheet,Corrugated Sheet,Pipe,Coil Sheet Thickness 0.1-5mm, or as Required Applications 1% Zinc Layer Thickness Z10-Z600 Hardness Soft,MID Hard,Full Hard Material Galvanized Steel MOQ 1 Ton Delivery Time 5-10 Days Technics Hot Dipped, Hot Rolled, Cold Rolled Edges Mill Edge, Slit Edge Length 2000-6000mm or Customer Production Width 1000-1500mm or Customer Production Model No. Dx51d Dx52D Dx53D DC51D DC52D DC53D SGCC Sgcd Sgce Production Time 5-7 Workdays Delivery Term Fob, CIF, CFR,EXW Transport Package Marine Standard Packing Specification 4x8ft/ 5x10ft/ as required Trademark HGS Origin Shanghai HS Code 7210490000 Production Capacity 50000pieces/YearProduct Description

Prepainted/Regular Spangles/SGC340 SGC440/Galvanized/Zinc Coated/Galvalume/Corrugated/Roofing Sheet/Aluminium/Cold Rolled/Roll/Steel/PPGL/Gl/Al/Gi/Coil/Coil

Prepainted/Regular Spangles/SGC340 SGC440/Galvanized/Zinc Coated/Galvalume/Corrugated/Roofing Sheet/Aluminium/Cold Rolled/Roll/Steel/PPGL/Gl/Al/Gi/Coil/Coil

Galvanized Steel Supplier - Sheet & Coil

What is Galvanizing?

Galvanizing, or galvanization, is a manufacturing process where a coating of zinc is applied to steel or iron to offer protection and prevent rusting. There are several galvanizing processes available, but the most commonly offered and used method is called hot-dip galvanizing.

Galvanized steel is among the most popular steel types because of its extended durability, having the strength and formability of steel plus the corrosion protection of the zinc-iron coating. The zinc protects the base metal by acting as a barrier to corrosive elements, and the sacrificial nature of the coating results in a long-lasting and high-quality steel product.

This versatility makes it applicable to a variety of projects and industries, including agriculture, solar, automotive, construction, and so on. Below, we aim to provide a comprehensive description of how galvanized steel is processed, different galvanization methods, its benefits, and how it is used in these various industries.

The steps in the galvanizing process are as follows:

- The steel is cleaned in a degreasing solution

- After being cleaned, the steel is pickled by being lowered into a vat of diluted hot sulfuric acid

- The steel is then fluxed in an aqueous solution (typically zinc-ammonium chloride)

- After the flux, the steel is galvanized through immersion in a vat of molten zinc

- Afterward, the steel is inspected for consistency and a complete coating

Building Material Hot Dipped Galvanized Aluzinc Galvalume Zinc Coated Steel Roofing Sheet Roof steel Tiles Gi Galvanized Steel Sheet for Construction

Building Material Hot Dipped Galvanized Aluzinc Galvalume Zinc Coated Steel Roofing Sheet Roof steel Tiles Gi Galvanized Steel Sheet for Construction

| Technical Standard | EN10147/EN10142/DIN 17162/JIS G3302/ASTM A653 |

| Steel Grade | Dx51D, Dx52D, Dx53D, DX54D, S220GD, S250GD, S280GD, S350GD, S350GD, S550GD; SGCC, SGHC, SGCH, SGH340, SGH400, SGH440, SGH490, SGH540, SGCD1, SGCD2, SGCD3, SGC340, SGC340 , SGC490, SGC570; SQ CR22 (230), SQ CR22 (255), SQ CR40 (275), SQ CR50 (340), SQ CR80(550), CQ, FS, DDS, EDDS, SQ CR33 (230), SQ CR37 (255), SQCR40 (275), SQ CR50 (340), SQ CR80 (550); or Customer's Requirement |

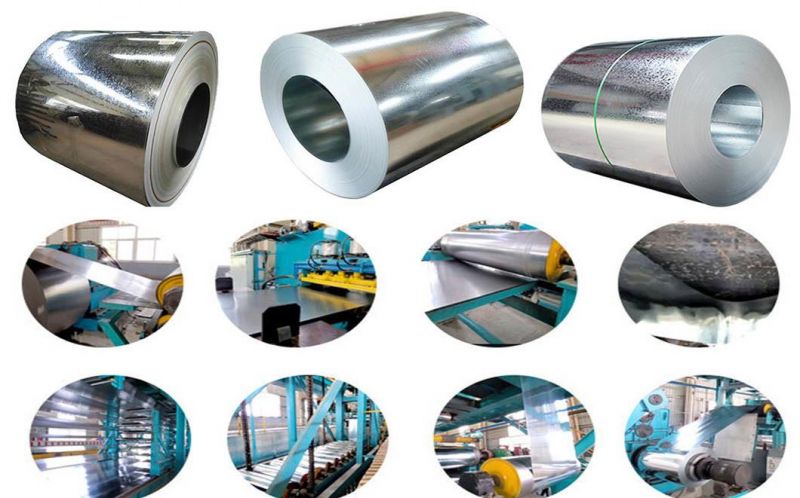

| Type | Coil/Sheet/Plate/Strip |

| Thicness | 0.12~6.0mm or customer's requirement |

| Width | 600~1500mm according to customer's requirement |

| Type of Coating | Hot Dipped Galvanized Steel(HDGI) |

| Zinc Coating | 30-275g/m2 |

| Surface Treatment | Passivation(C), Oiling(O), Lacquer sealing(L), Phosphating(P), Untreated(U) |

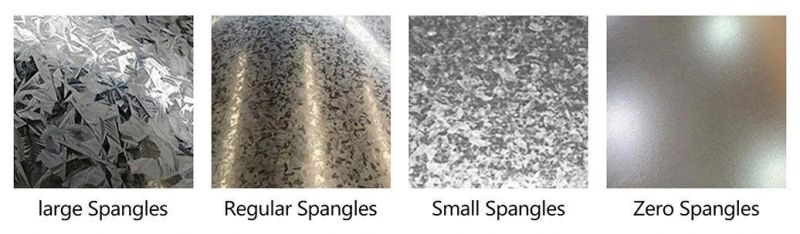

| Surface Structure | Normal spangle coating(NS), minimized spangle coating(MS), spangle-free(FS) |

| Quality | Approved by SGS,ISO |

| ID | 508mm/610mm |

| Coil Weight | 3-20 metric ton per coil |

| Package | Water proof paper is inner packing,galvanized steel or coated steel sheet is outer packing , side guard plate,then wrapped by seven steel belt.or according to customer's requirement |

| Export market | Europe, Africa, Central Asia, Southeast Asia, Middle East, South America, North America, etc |

What are the advantages of galvanized steel?

Many different industries utilize galvanized steel primarily because it has such a wide array of benefits for industries to take advantage of, including having:

Low initial cost compared to most treated steels. In addition, galvanized steel is immediately ready to use when delivered. It does not require additional preparation of the surface, inspections, painting/coatings, etc. sparing companies more costs on their end.

Longer life. With galvanization, a piece of industrial steel is expected to last more than 50 years in average environments, and can last over 20 years with severe water exposure. There is no maintenance required. The increased durability of the steel's finished product also increases the product's reliability.

The sacrificial anode ensures that any damaged steel is protected by the surrounding zinc coating. It doesn't matter if the steel section is completely exposed; the zinc will still corrode first. The coating will corrode preferentially to the steel, creating a sacrificial protection to the areas that are damaged.

Rust resistance from the zinc coating. The iron elements in steel are incredibly prone to rusting, but the addition of zinc acts as a protective buffer between the steel and any moisture or oxygen. Galvanized steel is very protective, including sharp corners and recesses that couldn't be protected with other coatings, making it resistant to damage. Different methods of galvanizing

Different methods of galvanizing

As stated above, there are several different processes for galvanizing steel.

Hot-Dip Galvanizing

The first and foremost method for galvanization is hot-dip galvanizing. The process is very similar to what the name suggests! In this method, steel or iron is dipped in a molten pool of zinc that maintains a temperature of around 860°F (460 °C). This molten bath begins a metallurgical bond between the zinc and the receiving metal. After the metal is pulled from the bath, it reacts to being exposed to the atmosphere, and the pure zinc mixes with oxygen to form zinc oxide. The zinc-oxide further reacts to carbon dioxide and forms zinc carbonate, which makes up the final protective coating on the material. The tell-tale sign of a hot-dipped galvanized material is the presence of a crystalline-like pattern on the surface, sometimes referred to as "spangle."

The hot-dipped galvanizing method is an economical choice that can be quickly executed on both simple and complex shapes.

The hot-dipped galvanizing method is an economical choice that can be quickly executed on both simple and complex shapes.

What industries utilize galvanized steel?

Galvanized metals are used everywhere!

The bodies of cars and many bicycles are made from galvanized metals. Some drinking water pipes are still made from galvanized steel. Cool rolled sheet metal is also frequently galvanized. Nuts, bolts, tools, and wires of all kinds are now galvanized because it is a cheap process, and helps boost the metal's lifespan!

Galvanized steel, in particular, is often what is used in modern "steel frame" buildings. Galvanized steel is also used to create structures like balconies, verandahs, staircases, ladders, walkways, and more. Galvanized metal is the ideal choice if your project will live outside after it's done. Fences, roofs, outdoor walkways, these are all great choices for galvanized metal!

- Wind & solar industries - Solar projects must have a continuous workflow once installed and any repairs/maintenance results in disruption to service (a.k.a. revenue loss). This means that hot-dipped galvanized steels are popular in solar projects for their corrosion protection. It is also popular for its 'environmental' friendliness because it does not produce emissions and ensures decades without maintenance. For example, it is often utilized in the agriculture industry because the equipment is susceptible to being easily corroded, creating a demand for tougher, more resilient equipment. Hot-dip galvanized steel provides corrosion protection that can often last for decades, even when exposed to the harsh environment of farming.

- Automotive industry - Though only used on luxury models up until the 1980s, the use of zinc-coated bodies for automobiles is now the norm in auto manufacturing. The 'body-in-white' of a car makes up about 80% of the body, all using galvanized steel. The rust -resistance of galvanized steel is also a good marketing tool for the automotive industry because it can provide 'anti-rust warranties' to customers.

- Construction industry - Whether for residential or commercial, the durability of galvanized steel has made it popular for over a century in the construction industry. It is also selected for construction because of its aesthetics; The 'shine' that galvanized steel provides gives it a contemporary feel and is popular in modern architectural designs. Also, it isn't just used for large structural pieces but things like fencing, gutters, rails, tubing, poles, and much more.

- Telecommunication industry - Phone lines are not an easy maintenance job, they are tall and often difficult to reach. Hot-galvanized steel can be used on phone wiring and equipment boxes which decreases the risk of damage and need for maintenance at all.

Shanghai Huagang Steel Co., Ltd. is one of the leading manufactories with ISO 9001 certificate who is specializing in manufacturing & exporting various kinds of steel pipes, steel plate, steel coil, round bar, flat bar, angle bar, H beam and other steel products in China. We owned the complete production technique and related equipment for coking, sintering, iron, steel, steel rolling etc, also including the related energy source power system. Meanwhile, we have reached the production technique` s completeness and systematicness at the modern steel industry. The company's annual sales amount is more than 100 million yuan.

Through the global sales network, the products sell well in domestic and foreign markets, Huagang Steel has exported steel products to over 100 countries in the world. Our products are marketed widely all over the country and exported to North American, Europe, Middle East, South American, Southeast Asia, Africa, Australia etc and get highly appreciated for our quality and service.

We now have 5 branch offices in China now, the head factory is located in ChenQiao Road, Fengxian District, Shanghai.We have been engaged in stainless steel business since 2009,with 12 years growth,Huagang Steel has become a competitive steel conglomerate in China.

Our company aims to provide customers with high-quality and low-price steel products and strives to create value for customers. We have advanced processing equipment and powerful logistics distribution system, which can meet customers' various needs at any time.

We adhere to the principle of "customer first" to provide our customers with high-quality services. Our company has won the trust and praise from customers with the business advantages of complete specifications, cheap price and fast transmission, and the service concept of keeping promise and focusing on quality

FAQQ1.Are you a manufacturer or trader?

FAQQ1.Are you a manufacturer or trader?We are a manufacturer ,and we can have our own factory produced many steel products.

Q2.Whether your company supports Trade Assurance order?

Yes , we can (100% product quality protection;100% on-time shipment protection; 100% payment protection)

Q3.Can we get the some samples?Any charges?

Yes,you can get available samples in our stock.If the samples from new production, we will charge some reasonable cost, but this amount will be deducted from your first order.

Q4.How do we build up business relations with your company ?

Send us your requirement which includes size , coating info ,parameters,quantity ,destination .

Q5.What is the MOQ?

We can accept small orders.Please feel free to contact us, we can meet your requirements.

Q6.What's your advantage?

With high-quality products and efficient customer service, we adhere to the principle of customer first.