En 10219 S235jrh/S355nh Carbon Steel Round/Rectangular Pipes

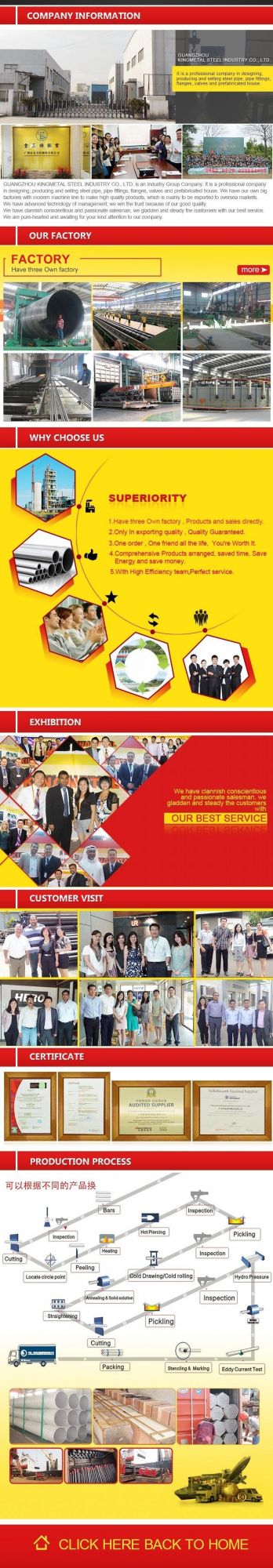

Guangzhou Kingmetal Steel Industry Co., Ltd.- Type:Seamless

- Technique:Hot Rolled

- Material:Carbon Steel

- Surface Treatment:Black

- Usage:Pipeline Transport, Machinery Industry, Mining, Construction & Decoration, Special Purpose

- Section Shape:Rectangular

Base Info

- Model NO.:KM-81

- Diameter:20~3020mm in Theory

- MOQ:10 Mt,Size

- Deliver Lead-Time:10-15 Days After Receipt by T,T, or L,C

- Loading Port:Chinese Main Port

- Certificate:ISO

- Payment:L,C, T,T

- Transport Package:Standard Sea-Worthy Package

- Specification:5.5, 6.5, 7, 8, 9, 10, 12, 14mm and More

- Trademark:Kingmetal

- Origin:China

- Production Capacity:10000tons,Month

Description

Basic Info.

Model NO. KM-81 Diameter 20~3020mm in Theory MOQ 10 Mt/Size Deliver Lead-Time 10-15 Days After Receipt by T/T, or L/C Loading Port Chinese Main Port Certificate ISO Payment L/C, T/T Transport Package Standard Sea-Worthy Package Specification 5.5, 6.5, 7, 8, 9, 10, 12, 14mm and More Trademark Kingmetal Origin China Production Capacity 10000tons/MonthProduct Description

Kingmetal Steel Pipe Produces a full range of EN 10219 Pipe in:

- Grade S235JRH/S275J0H/S275J2H/S355J0H/S355J2H/S355K2H

- Round Pipe Size: outside diameter 88.9-457mm, thickness 2.5-16mm of ERW Pipe

- Round Pipe Size: outside diameter 219-2540mm, thickness 4-25.4mm of SSAW Pipe

- SHS Size: side length 20-800mm, thickness 2-30mm

- RHS Size: side length 20-500X20-750mm, thickness 2-30mm

Scope

Seamless Steel Pipe, ERW High-Frequency Welded Pipes, and SSAW/LSAW Welded Pipes

Materials and Manufacture

The steel for welded pipe shall be made by one or more of the following processes: open-hearth, electric furnace, or basic-oxygen. Structural Hollow Sections shall be manufactured by electric welding or submerged arc welding without subsequent heat treatment.

Chemical Requirements

| Steel Grade | C Max % | Si Max % | Mn Max % | P Max % | S Max % | N Max % |

|---|---|---|---|---|---|---|

| S235JRH | 0.17 | - | 1.4 | 0.04 | 0.04 | 0.009 |

| S275J0H | 0.2 | - | 1.5 | 0.035 | 0.035 | 0.009 |

| S275J2H | 0.2 | - | 1.5 | 0.03 | 0.03 | - |

| S355J0H | 0.22 | 0.55 | 1.6 | 0.035 | 0.035 | 0.009 |

| S355J2H | 0.22 | 0.55 | 1.6 | 0.03 | 0.03 | - |

| S355K2H | 0.22 | 0.55 | 1.6 | 0.03 | 0.03 | - |

Tensile Requirements

| Steel Grade | Min Yield Strength Mpa T≤16 | Min Yield Strength Mpa 16 < T≤40 | Tensile Strength Mpa T≤3 | Tensile Strength Mpa 3 < T≤40 | Min Elongation T < 40 | Min Impact Ennergy -20ºC J | Min Impact Ennergy 0ºC J | Min Impact Ennergy 20ºC J |

|---|---|---|---|---|---|---|---|---|

| S235JRH | 235 | 225 | 350-510 | 360-510 | 24 | - | - | 27 |

| S275J0H | 275 | 265 | 430-580 | 410-560 | 20 | - | 27 | - |

| S275J2H | 275 | 265 | 430-580 | 410-560 | 20 | 27 | - | - |

| S355J0H | 355 | 345 | 510-680 | 470-630 | 20 | - | 27 | - |

| S355J2H | 355 | 345 | 510-680 | 470-630 | 20 | 27 | - | - |

| S355K2H | 355 | 345 | 510-680 | 470-630 | 20 | 40 | - | - |

Permissible Variations

Wall Thickness:Plus or minus 12.5%

Weights:Plus or minus 10%

Hydrostatic Testing

Hydrostatic inspection test pressures for plain end and threaded and coupled pipe are specified. Hydrostatic pressure shall be maintained for not less than 5 seconds for all sizes of seamless and electric-resistance-weld pipe.

Mechanical Tests Specified

Cast Analysis-One result per delivery item

Tensile Test-One result per delivery item

Impact Test-Per Heat Number

Surface Condition and Dimensions- 10%

NDT of the Weld-All products, full length