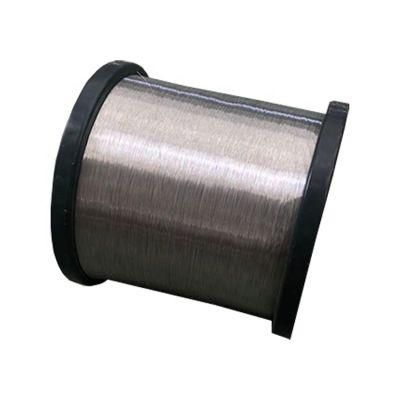

Galvanized Steel Zinc Aluminum Alloy Wire for Aerial Ropeways and Cable Cars

SHANGHAI GM TECH CO., LTD.- Surface:Zinc Aluminum Alloy

- Technique:Galvanized

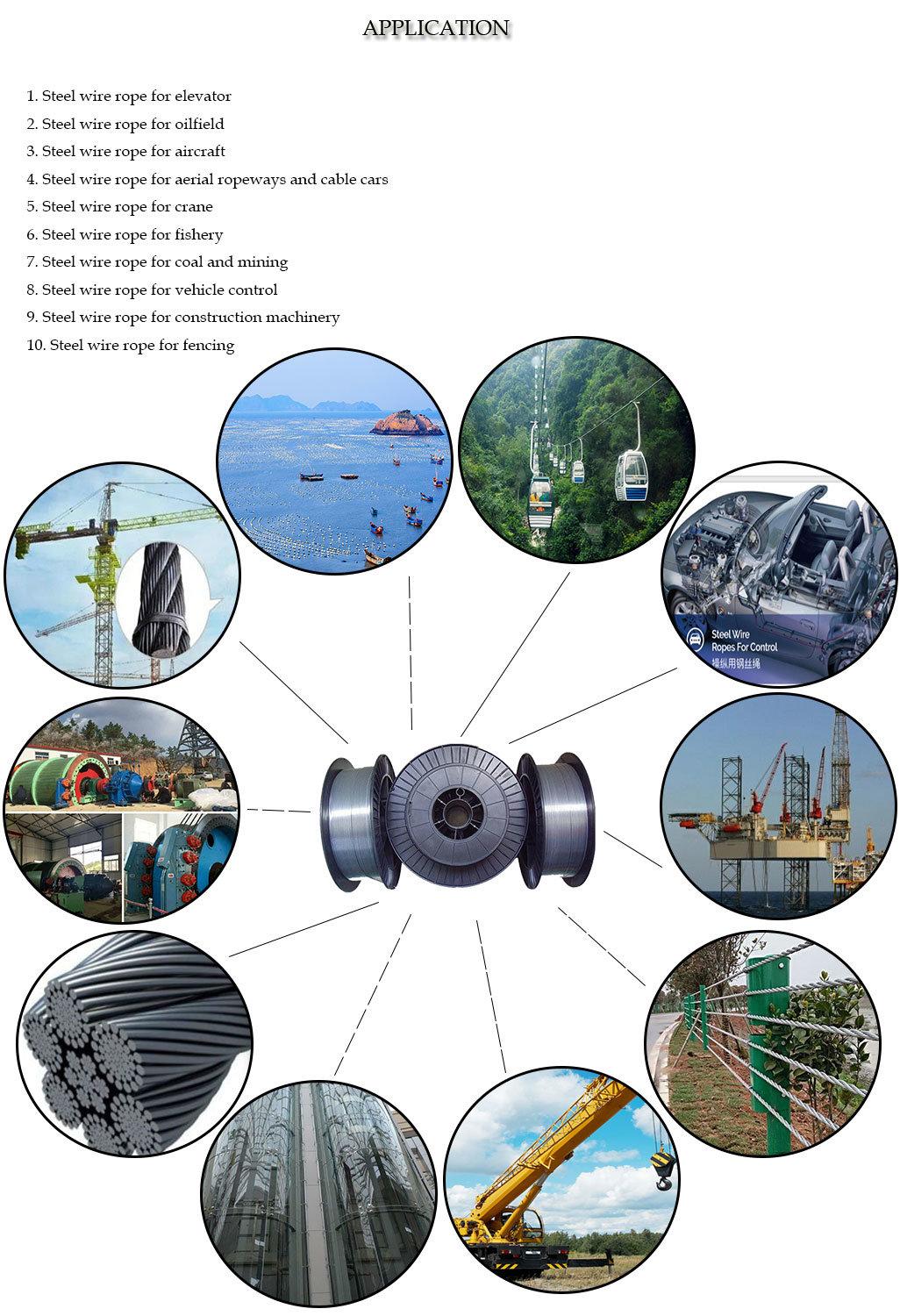

- Application:Rope, Packaging, Netting, Manufacturing, Fencing, Construction

- Alloy or Not:Alloy

- Features:Corrosion Resistant+Excellent Fatigue

- Specification(mm):1.4

Base Info

- Diameter(mm):1.4±0.02

- Tensile Strength(MPa):980~1100

- Plating Weight(G/M2):≥130

- Al Content(%):10±2

- Transport Package:Pallet

- Specification:0.08~0.4mm

- Trademark:OEM,ODM

- Origin:China

- Production Capacity:1000tons,Month

Description

The Zn-Al alloy is made by 90% Zinc and 10% Aluminium. It is used to produce metal wire (0.08 mm to 6.00 mm diameter)with high corrosion resistance. It is often used as protective coating in metal parts. Compared with hot dip galvanized metal wire, Zn-Al alloy metal wire has better coherence, resistance to wear and corrosion resistivity. So it is an ideal anticorrosion material to sea water.Superior quality with high corrosion resistant

The Zn-Al alloy is made by 90% Zinc and 10% Aluminium. It is used to produce metal wire (0.08 mm to 6.00 mm diameter)with high corrosion resistance. It is often used as protective coating in metal parts. Compared with hot dip galvanized metal wire, Zn-Al alloy metal wire has better coherence, resistance to wear and corrosion resistivity. So it is an ideal anticorrosion material to sea water.Superior quality with high corrosion resistantIn the salt spray test, zinc conventional general also assured me that the use of the effects of chemicals and sea water was stable with a serious industrial area and books have more than tripled at least corrosion resistance life compared to the heartstrings, It has been able to drastically reduce the replacement frequency less than the hot dip galvanized metal wire, etc. in developed countries, its use has gradually increased.

Excellent fatigue

Results were measured by Reverse bending fatigue tester, zinc conventional is increased fatigue life value of 1.2 times or more chord ratio. Galvanized and Zinc + In a manner to maintain a stable quality of the metal structure and ongoing management of aluminum alloy plating process, the results of fatigue tests come out good adhesion of the alloy plating is the excellence of conventional

The manufacturing process:

The manufacturing process:Wire rod production→Wire rod drawing→Zn-Al application→Finish products

Specification Parameters:

| No. | Specification(mm) | Diameter(mm) | Tensile Strength(Mpa) | Plating Weight(g/m2) | Al Content(%) |

| 1 | 0.13 | 0.13±0.015 | ≥2100 | ≥10 | 10±2 |

| 2 | 0.14 | 0.14±0.010 | ≥2450 | ≥8 | 10±2 |

| 3 | 0.14 | 0.14±0.010 | ≥2700 | ≥8.5 | 10±2 |

| 4 | 0.34 | 0.34±0.015 | ≥2260 | ≥20 | 10±2 |

| 5 | 0.39 | 0.39±0.015 | ≥2000 | ≥20 | 10±2 |

| 6 | 1.4 | 1.4±0.02 | 980~1100 | ≥130 | 10±2 |

| 7 | 1.6 | 1.6±0.02 | 1050~1150 | ≥150 | 10±2 |

| 8 | 2.0 | 2.0±0.07 | 1200~1350 | ≥180 | 10±2 |

| 9 | 2.5 | 2.5±0.07 | 1200~1350 | ≥200 | 10±2 |

| 10 | 3.0 | 3.0±0.08 | 1100~1250 | ≥230 | 10±2 |

| 11 | 4.0 | 4.0±0.10 | 1150~1300 | ≥300 | 10±2 |