High Manganese Mn13 Abrasion Resistant Wear Plate

Shandong Heng Steel Group Co., Ltd.- Certification:ISO, RoHS, IBR

- Standard:ASTM, AISI, JIS, DIN, BS

- Type:Steel Plate

- Warranty:Online Technical Support

- After-sales Service:Yes

- Surface Treatment:Hot-Rolled,Controlled;Rolling,Normalizing;...

Base Info

- Delivery Time:About 15-25 Workdays

- MOQ:5 Tons

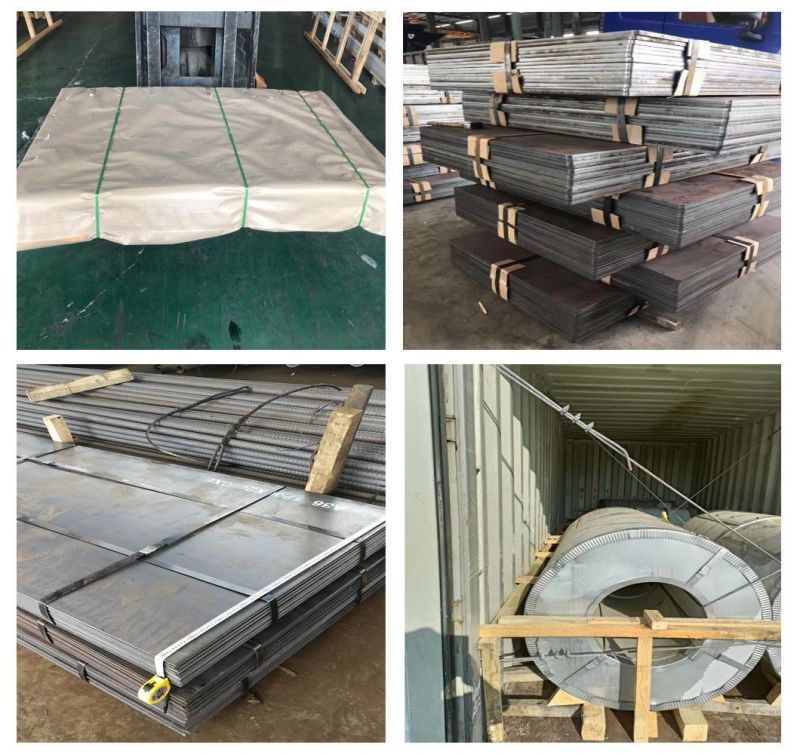

- Package:Standard Export Package

- Test:BV,SGS---Mtc

- Delivery Status:Hot-Rolled;Controlledrolling;Normalizing,

- Surface:Clean, Finishing,Blasting and Painting...

- Material:Xar400, Xar450,Mn13,Nm400,Nm500...

- Length:100-11800mm

- Width:1000-3000mm

- Thickness:2-300mm

- Name:High Manganese Mn13 Abrasion Resistant Wear Plate

- Stock:Stock

- Special Use:High-strength Steel Plate, Wear Resistant Steel

- Application:Wear Resistant Steel

- Technique:Hot Rolled

- Model NO.:High Manganese Mn13 Abrasion Resistant Wear Plate

- HS Number:72254099

- Original:China

- Use:Metal Constructions Such as Buildings,Bridges,Ship

- Transport Package:Standard Export Package

- Specification:0.5-300mm*1000-3000mm

- Trademark:HengSteel

- Origin:China

- HS Code:72254099

- Production Capacity:3000 Ton , Month

Description

Overview

Wear Resistant Steel Plate Specification

Standard

GradeDIN: XAR300,XAR400, XAR450, XAR500, XAR600, DILLIDUR400V,DILLIDUR450V,DILLIDUR500V; X120Mn12; 1.3401;

SSAB:WELDOX700,WELDOX900,WELDOX960;

NF: FORA400,FORA500,Creusabro4800,Creusabro8000;

EN: QUARD400,QUARD450,QUARD500 ; RAEX320,RAEX400,RAEX450,RAEX500; DUrostat400,DUrostat450,DUrostat500;

JIS: WEL-HARD400, WEL-HARD500; SUMIHARD-K340,SUMIHARD-K400,SUMIHARD-K500

GB: NM360,NM400,M450,NM500,NM550,NM600,NR360,NR400,B-HARD360,B-HARD400,B-HARD450,KN-55,KN-60,KN-63. Thickness 2-300mm (2-100mm usually used) Width 1000-3000mm (1000-2200mm usually used) Length 1000-12000mm or as your request Surface Clean, finishing,blasting and painting according to customer requirement Delivery

States Hot-rolled, Controlled rolling, Normalizing, Annealing, Tempering,

Quenching, N+T, Q+T,and other delivery states are available as required Certificate API,ISO,SGS,BV,CE etc Quality MTC will be provided with goods, third part inspection is acceptable, for example

BV,SGS. Package Standard export seaworthy package,suit for all kinds of transport,

or as required. Container

Size

20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High) 40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High) Trade term Ex-Work,FOB,CNF,CFR,CIF,etc Application Widely used in a variety of architectural and engineering structures,such as

1.) metal constructions such as buildings,bridges,ships;

2.) transmission tower, reaction tower;

3.) lifting transportation machinery;

4.) industrial furnace;boilers

5.) container frame, warehouse goods shelves, etc

Wear Resistant Steel Plate Chemical Composition and Mechanical Properties Chemical Composition(Max) Material C Si Mn P S Cr Ni Mo Ti Bt Als CEV NM300 0.23 0.70 1.60 0.025 0.015 0.70 0.50 0.40 0.050 0.0005-0.0006 0.010 0.45 NM360 0.25 0.70 1.60 0.025 0.015 0.80 0.50 0.50 0.050 0.0005-0.0006 0.010 0.48 NM400 0.30 0.70 1.60 0.025 0.010 1.00 0.70 0.50 0.050 0.0005-0.0006 0.010 0.55 NM450 0.35 0.70 1.70 0.025 0.010 1.10 0.80 0.55 0.050 0.0005-0.0006 0.010 0.60 NM500 0.38 0.70 1.70 0.020 0.010 1.20 1.00 0.65 0.050 0.0005-0.0006 0.010 0.65 NM550 0.38 0.70 1.70 0.020 0.010 1.20 1.00 0.70 0.050 0.0005-0.0006 0.010 0.72 NM600 0.38 0.70 1.90 0.020 0.010 1.50 1.00 0.70 0.050 0.0005-0.0006 0.010 0.76 Material Tensile MPA Elongation % Impact energy -20ºC HBW NM300 ≥1000 ≥14 ≥24 270-300 NM360 ≥1100 ≥12 ≥24 330-390 NM400 ≥1200 ≥10 ≥24 370-430 NM450 ≥1250 ≥7 ≥24 420-480 NM500 ≥1250 ≥7 ≥24 ≥470 NM550 ≥1250 ≥7 ≥24 ≥530 NM600 ≥1250 ≥7 ≥24 ≥570 Grade C Si Mn P S Cr Mo Cu Ni B XAR400 0.20 0.80 1.50 0.025 0.010 1.00 0.50 -- -- 0.005 XAR450 0.22 0.80 1.50 0.025 0.012 1.30 0.50 0.30 -- 0.005

XAR5000.28 0.80 1.50 0.025 0.010 1.00 0.50 -- -- 0.005

XAR6000.40 0.80 1.50 0.025 0.010 1.50 0.50 -- 1.50 0.005 Grade Yield Strength

Reh MPa Tensile Strength

Rm MPa Elongation BH

(Brinell Hardness) XAR400 1150 1300 ≥12 360-440 XAR450 1200 1350 ≥10 410-490 XAR500 1500 1600 ≥9 450-530 XAR600 -- -- -- ≥550 Material C Si Mn P S Cr Mn13 1.1~1.3 0.3~0.5 12~13 ≤0.100 ≤0.040 ≤1.5 X120Mn12 1.1~1.3 0.3~0.5 12~13 ≤0.100 ≤0.040 ≤1.5 1.3401 1.1~1.3 0.3~0.5 12~13 ≤0.100 ≤0.040

≤1.5 SCMnH11 0.9~1.5 0.3~1.0 10~15 ≤0.100 ≤0.050 ≤1.5 ASTM A128 1.1~1.3 0.3~0.5 12~13 ≤0.100 ≤0.050 ≤1.5

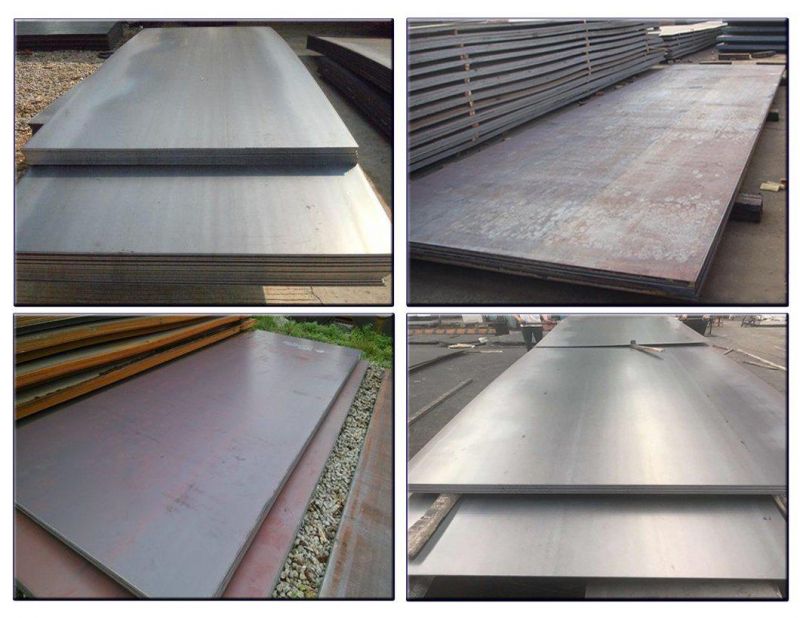

Production process

Production process

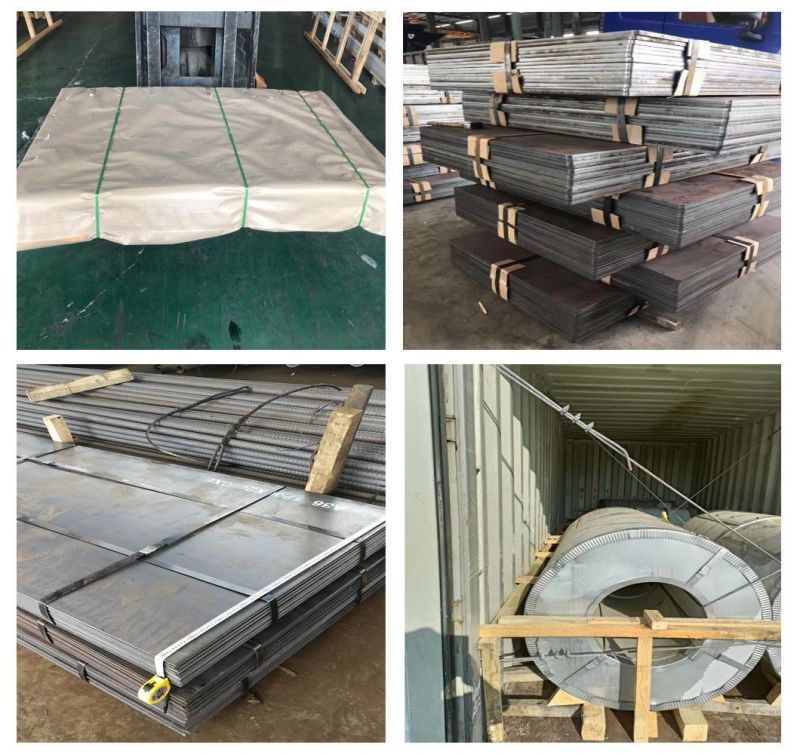

Packaging & Shipping

Packaging & Shipping

Application

Application

More Products

More Products

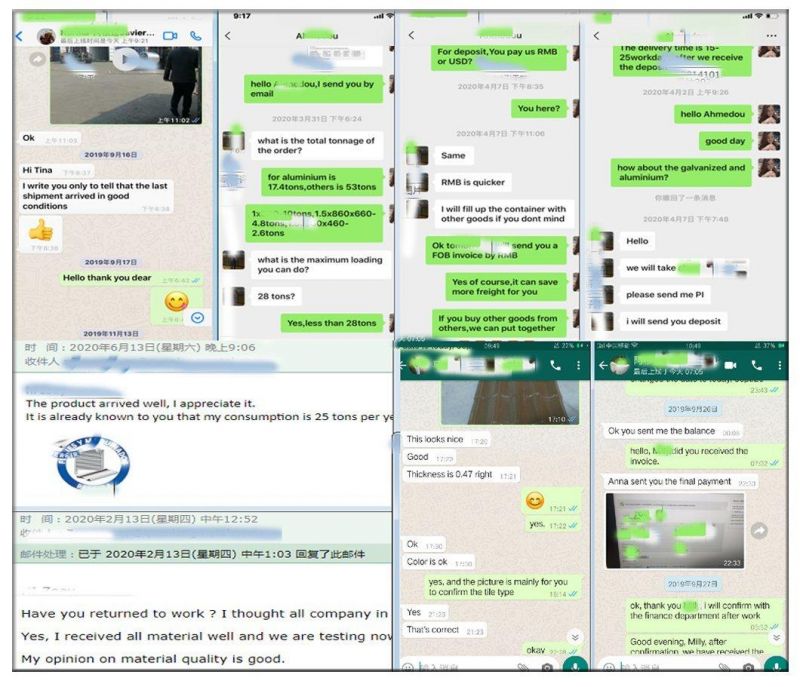

Customers & High praise

Customers & High praise

Certifications

Certifications

Wear Resistant Steel Plate Specification

Standard

Grade

SSAB:WELDOX700,WELDOX900,WELDOX960;

NF: FORA400,FORA500,Creusabro4800,Creusabro8000;

EN: QUARD400,QUARD450,QUARD500 ; RAEX320,RAEX400,RAEX450,RAEX500; DUrostat400,DUrostat450,DUrostat500;

JIS: WEL-HARD400, WEL-HARD500; SUMIHARD-K340,SUMIHARD-K400,SUMIHARD-K500

GB: NM360,NM400,M450,NM500,NM550,NM600,NR360,NR400,B-HARD360,B-HARD400,B-HARD450,KN-55,KN-60,KN-63.

States

Quenching, N+T, Q+T,and other delivery states are available as required

BV,SGS.

or as required.

Size

1.) metal constructions such as buildings,bridges,ships;

2.) transmission tower, reaction tower;

3.) lifting transportation machinery;

4.) industrial furnace;boilers

5.) container frame, warehouse goods shelves, etc

Wear Resistant Steel Plate Chemical Composition and Mechanical Properties

XAR500

XAR600

Reh MPa

Rm MPa

(Brinell Hardness)

Production process

Production process Packaging & Shipping

Packaging & Shipping

Application

Application More Products

More Products

Customers & High praise

Customers & High praise

Certifications

Certifications