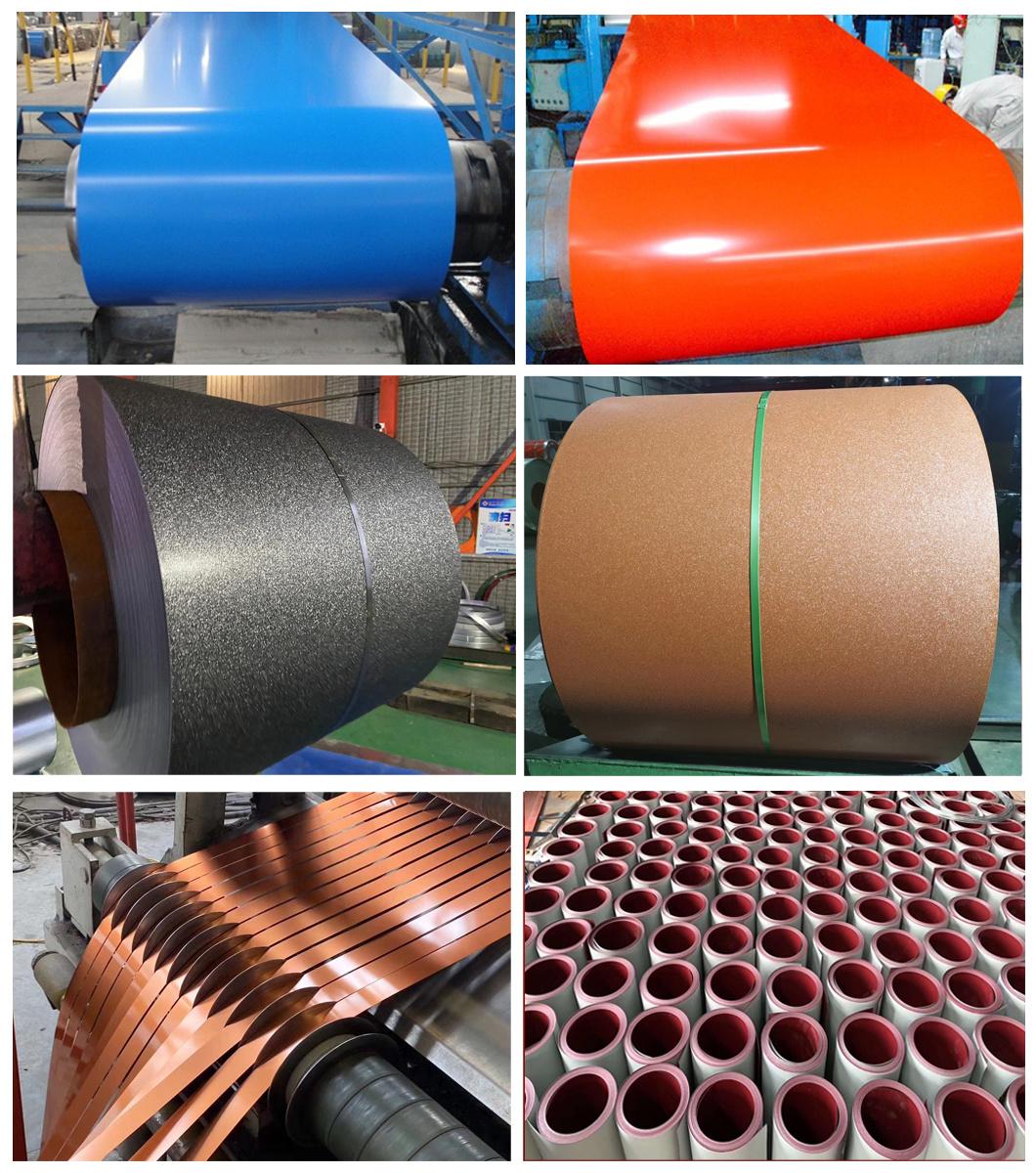

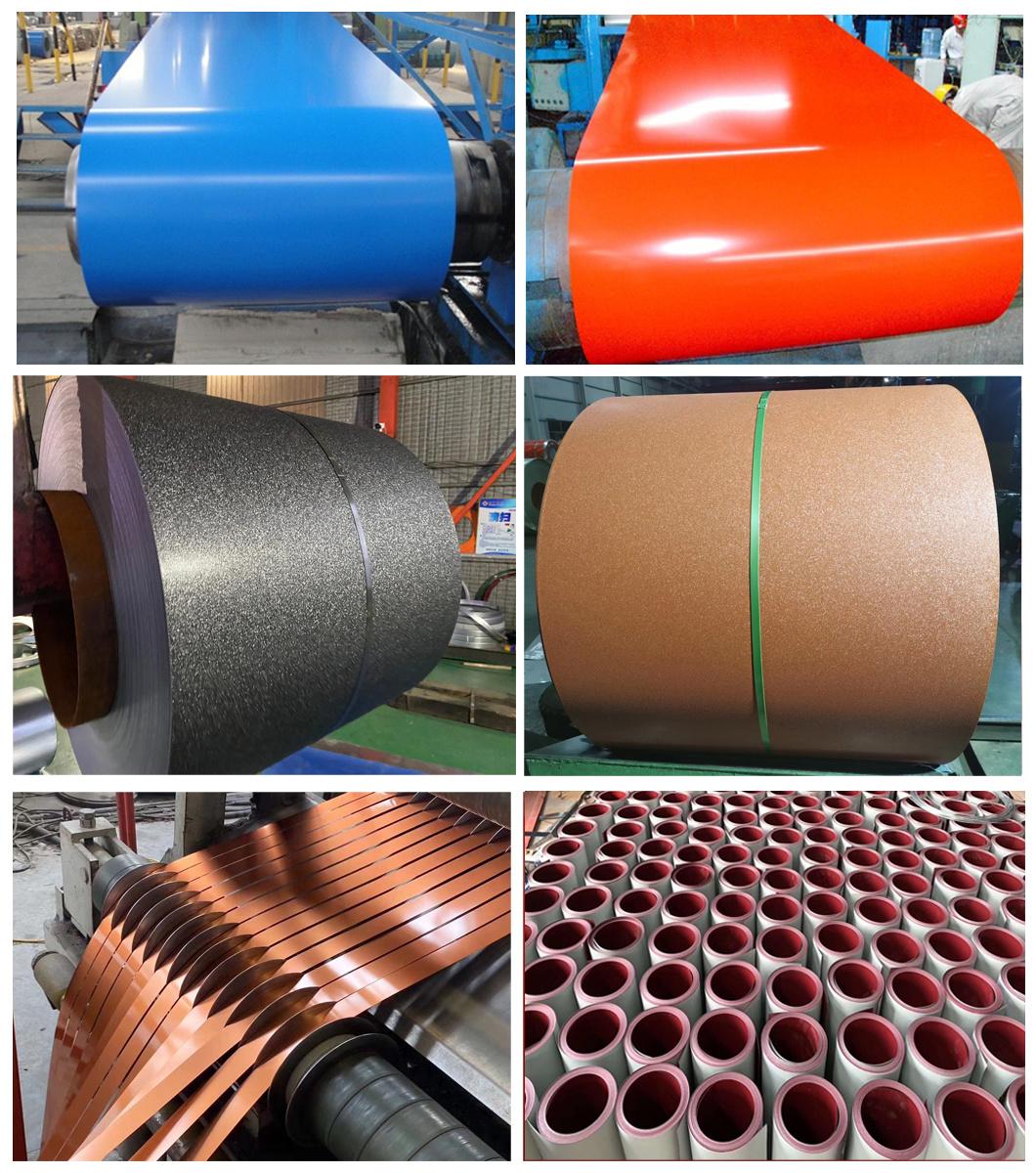

PPGI Ral Color Zn Coated Pre-Painted Dx51d Galvanized Steel Coil

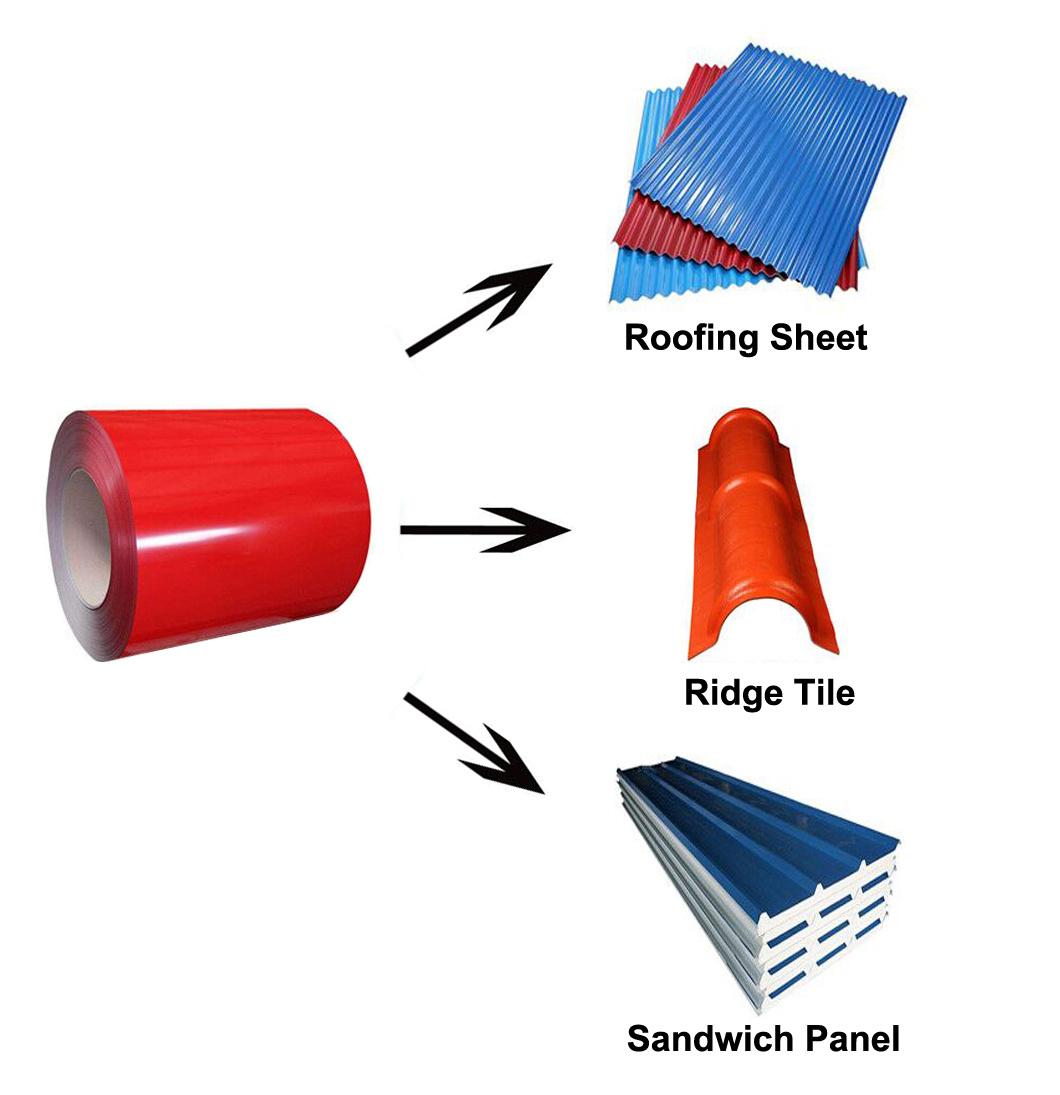

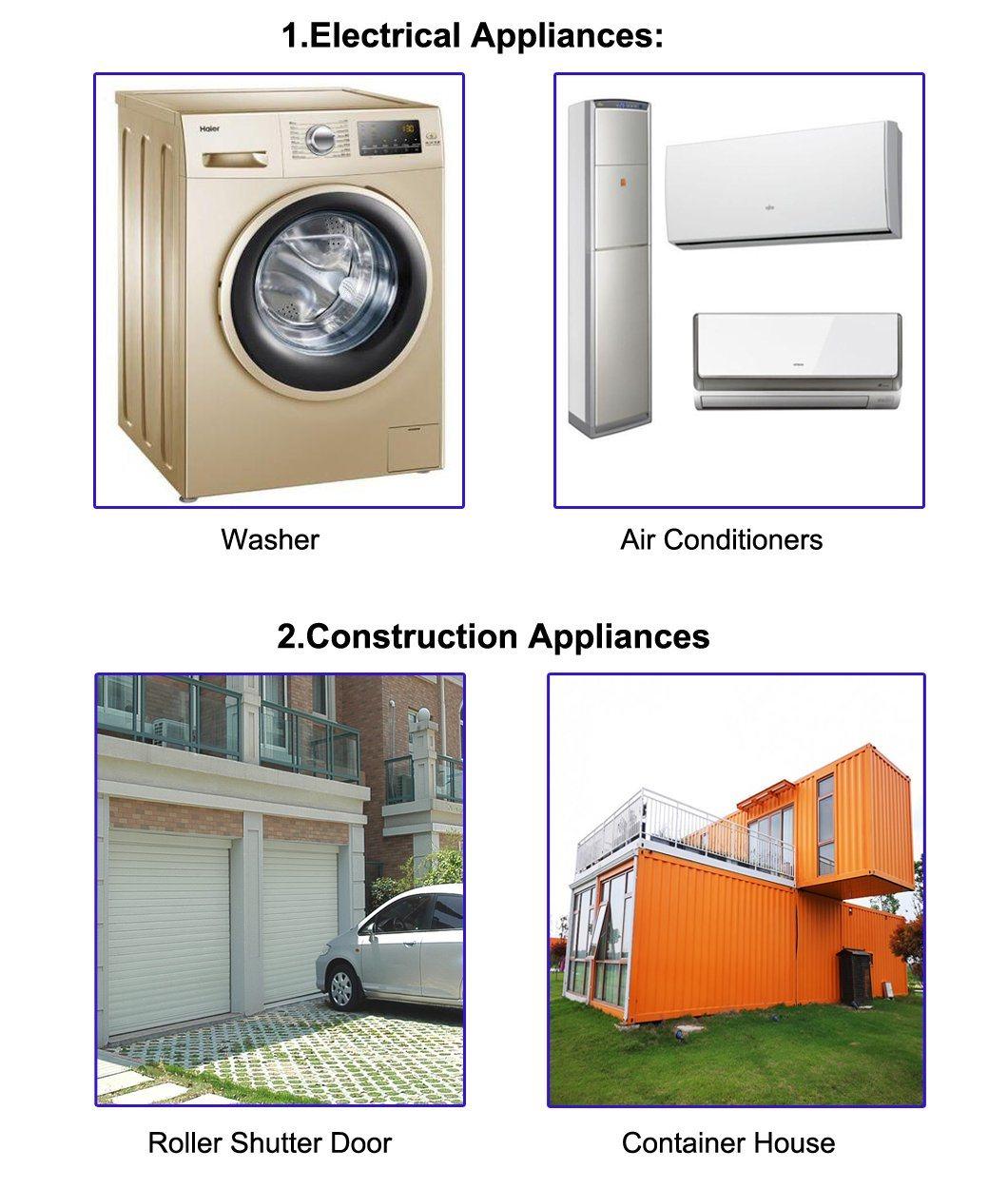

Shandong Heng Steel Group Co., Ltd.- Application:Building Material and Decoration, Outdoor Roofing

- Technique:Cold Rolled

- Surface Treatment:Coated

- Certification:ISO, RoHS, IBR

- Standard:ASTM, JIS, AISI, DIN

- Edge:Slit edge

Base Info

- Delivery Time:About 15-20 Workdays

- Use:Building Material and Decoration, Outdoor Roofing

- Original:China

- HS Number:7210701000

- MOQ:25 Tons

- Package:Standard Export Package

- Coating Type:PE, PVDF, PU, HDP...

- Process:Cold Rolled

- Coating:Top or Back Printed as Your Requiremnt

- Grade:Dx51d+Z, Dx52D+Z, SGCC, Sgcd, S250d+Z...

- Length:1000-12000 or Coil

- Width:600-1250mm

- Thickness:0.125-2mm

- Name:Zn Coated Pre-Painted Dx51d Galvanized Steel Coil

- Stock:Stock

- Model NO.:Zn Coated Pre-painted Dx51d Galvanized Steel Coil

- Loading Port:Tianjin, Qingdao

- Transport Package:Standard Export Package

- Specification:0.125-2.0mm*600-1250mm

- Trademark:Hengze

- Origin:China

- HS Code:7210701000

- Production Capacity:2000 Ton , Month

Description

Overview

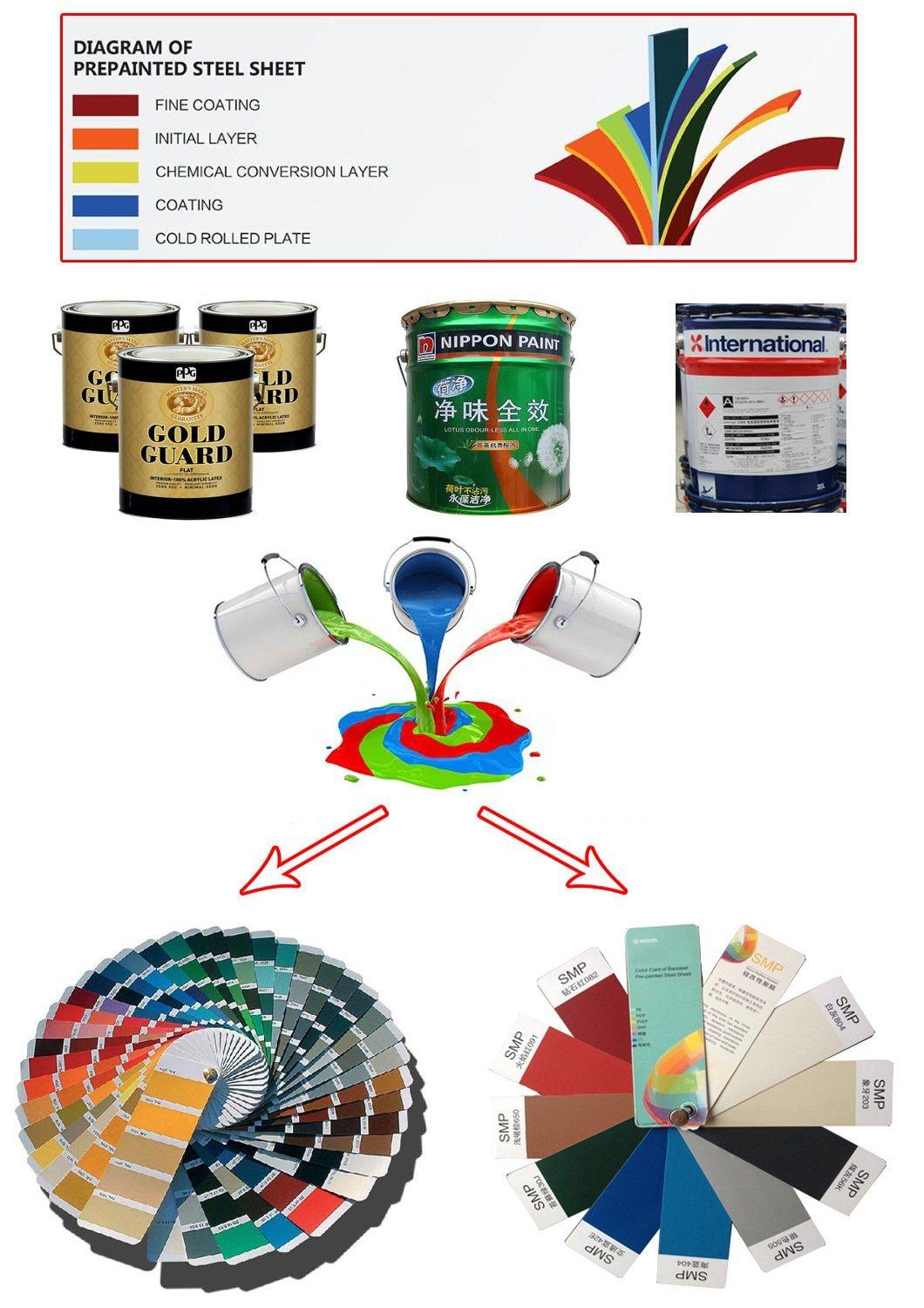

Prepainted Steel CoilsType of

substrate Hot dip galvanized, Galvalume, Electro galvanized,Zinc alloy, Cold rolled

steel, Aluminium Thickness 0.12-2mm Tolerance Thickness: ± 0.01mm Width 600-1250mm ( Normal:1250, 1200,1000,914 mm) Top Paint 10-25 micron(Normal:10-12mic) Back paint 5-12 micron(Normal:5-7mic) Coating Zn coating AZ coating 30-400gsm 30-400gsm Coil weight 3-9 tons or as your requirement. Coil ID 508/610 mm Grade Galvanized Galvalume SGCC/DX51D+Z, DX52D+Z,

SGCD/DX53D+Z,SGCE/DX54D+Z,

SGCH....... DX51D+AZ, DX52D+AZ, DX53D+AZ,

DX54D+AZ,SGLCC,SGLCD,SGLC4

40,SGLHC........ Coating type Top paint: PE, SMP, HDP, PVDF, PU Functions: Decorative, Machinability, Weather resistance, Scrath

resistance, Stain resistance, Chemical resistance, Adhesion resistance Primer paint: Polyurethane, Epoxy, PE Functions:Machinability, Corrosive resistance, Adhesion, Scrath

resistance Back paint: Epoxy, Modified polyester Functions: Scrath resistance, Bending adhesion, Corrosive resistance Type of

coating

process Front: Doulbe coated & double drying Back: Double coated & double drying, single coated & double drying Double coated & double drying is used for corrugated sheet Double coated & single drying is for sandwich panel Packing Standard export package .Plastic film in the first layer,second layer is Kraft

paper. Third layer is galvanized sheet. Application Building industry ,structural use, roofing, commercial use ,household

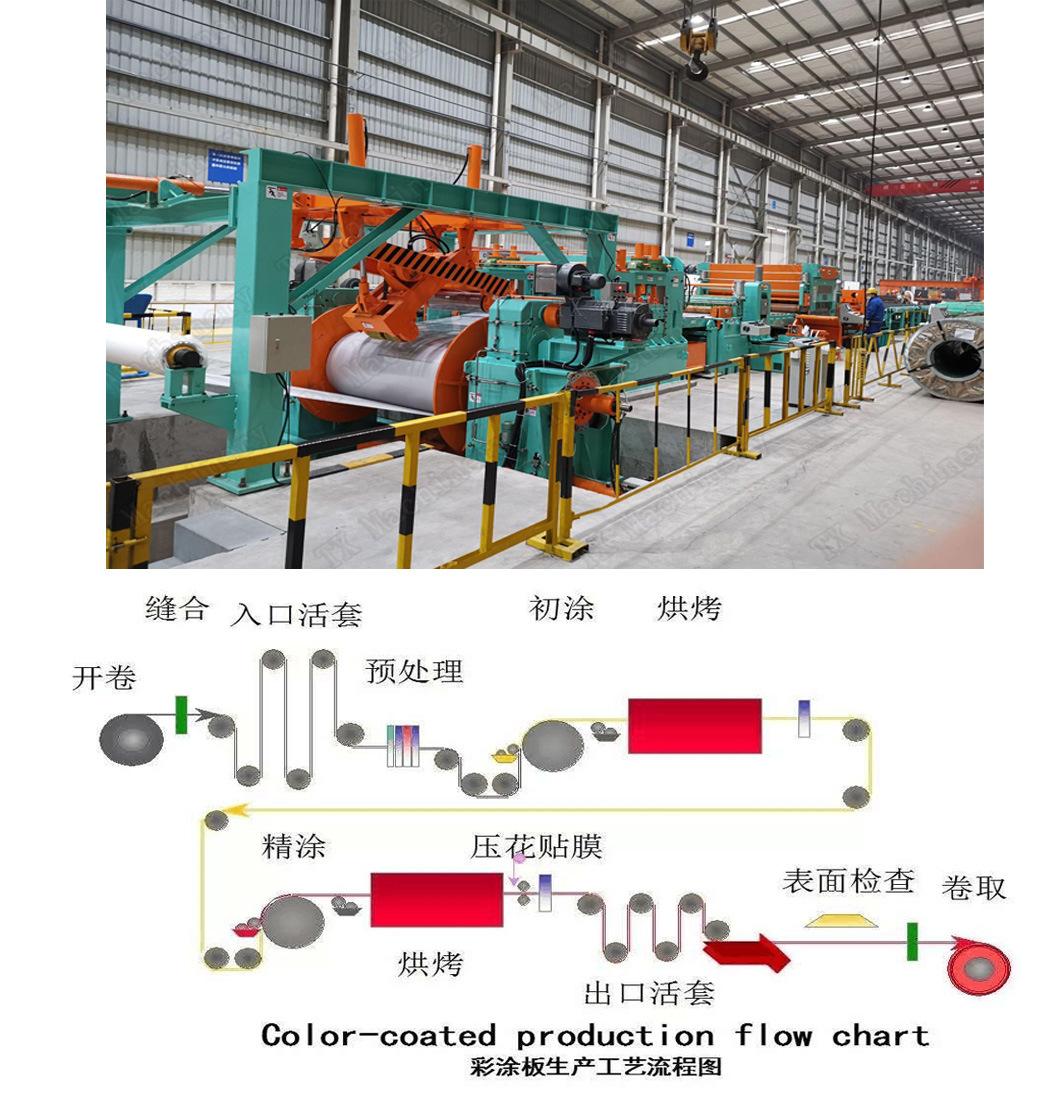

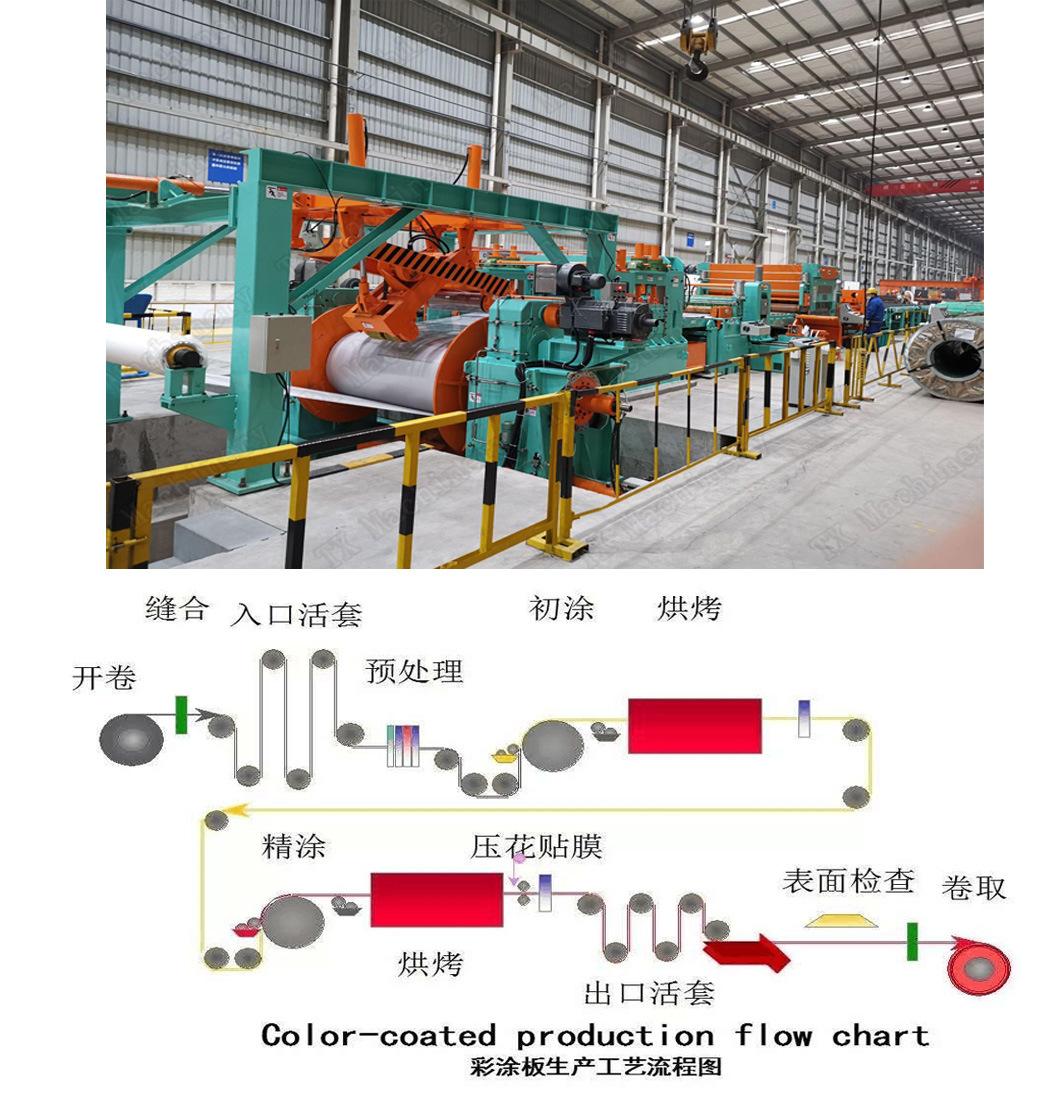

appliance, industry facilities, office buildings Q/BQB 420 DC51D+Z Ordinary use TDC51D DC52D+Z SPCD TDC52D DC53D+Z SPCE TDC53D S280GD+Z Structure use TS280GD S350GD+Z Structure use TS350GD S550GD+Z High strength structure use TS550GD ELECTRO GALVANIZED PLATE Q/BQB 430 SECC Ordinary use TSECC SECD SPCD TSECD SECE SPCE TSECE BLCE+Z Ordinary use TBLCE BLDE+Z SPCD TBLDE BUSDE+Z SPCE TBUSDE HOT DIP GALVALUME PLATE Q/BQB 425 DC51D+AZ Cold forming use TDC51D+AZ DC52D+AZ Cold forming use TDC52D+AZ S250GD+AZ Structure use TS250GD+AZ S300GD+AZ Structure use TS300GD+AZ S350GD+AZ Structure use TS350GD+AZ S550GD+AZ High strength structure use TS550GD+AZ  Product Process

Product Process

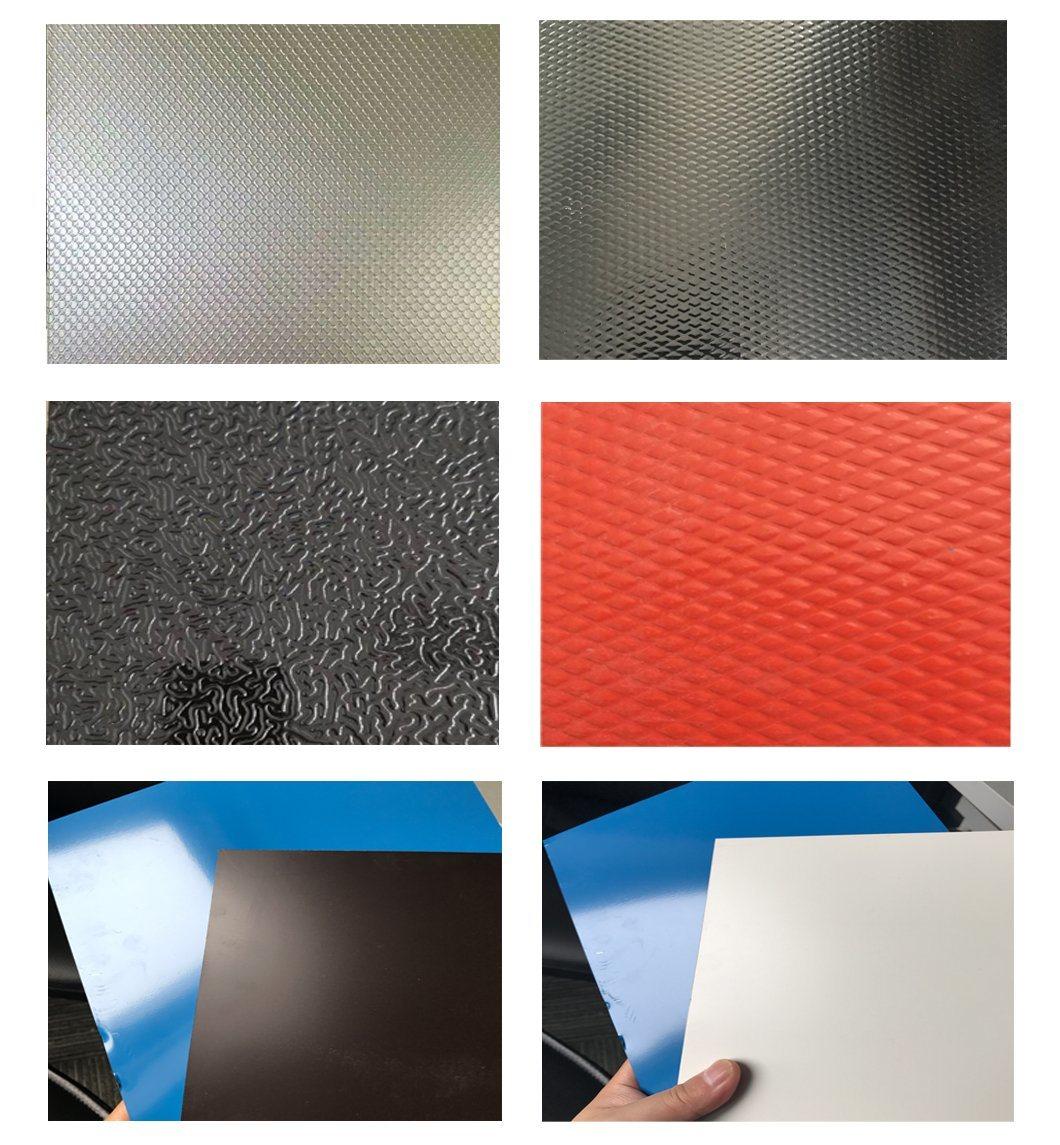

Surface

Surface Certificate&Customer Praise

Certificate&Customer Praise

substrate

steel, Aluminium

SGCD/DX53D+Z,SGCE/DX54D+Z,

SGCH.......

DX54D+AZ,SGLCC,SGLCD,SGLC4

40,SGLHC........

resistance, Stain resistance, Chemical resistance, Adhesion resistance

resistance

coating

process

paper. Third layer is galvanized sheet.

appliance, industry facilities, office buildings

Produce Show

Product Process

Product Process

Surface

Surface

Certificate&Customer Praise

Certificate&Customer Praise