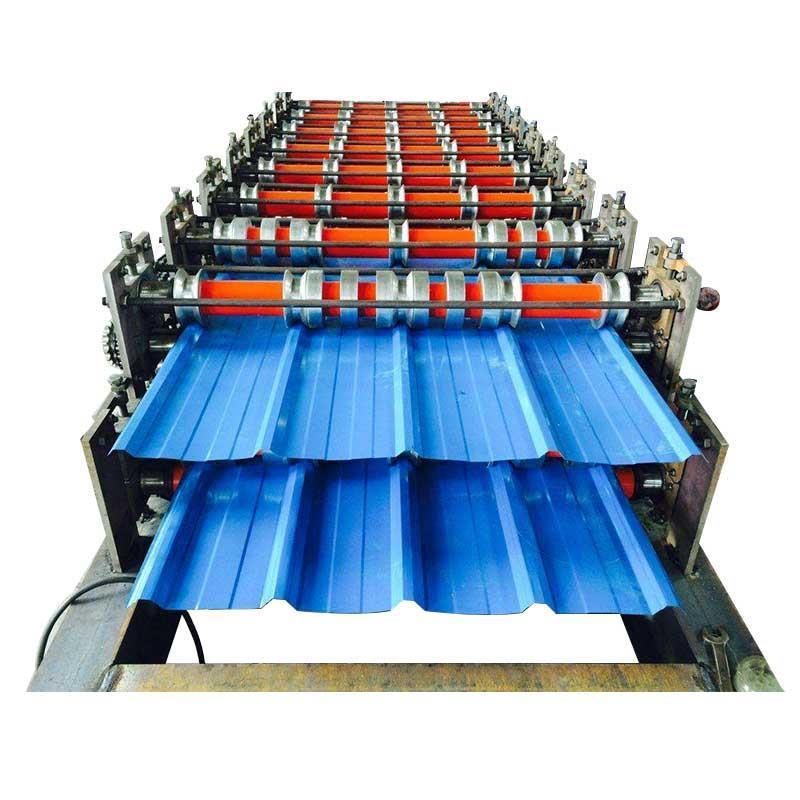

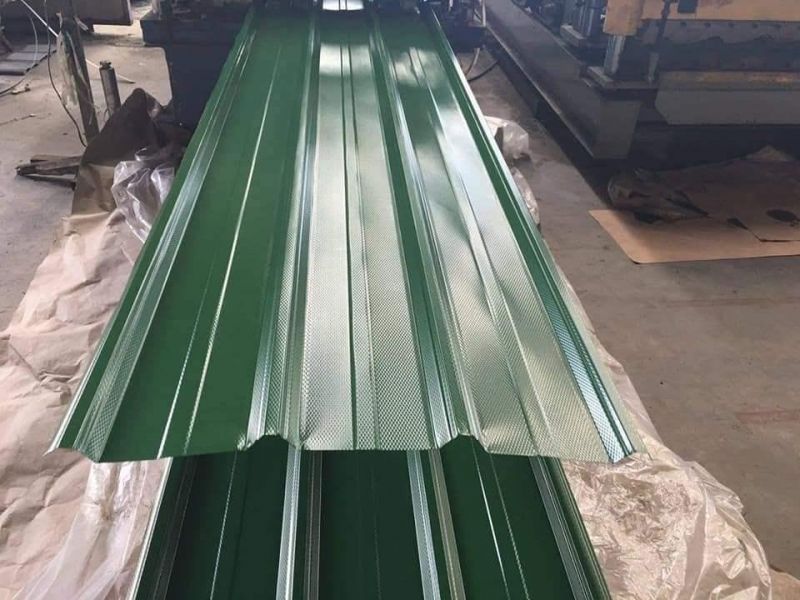

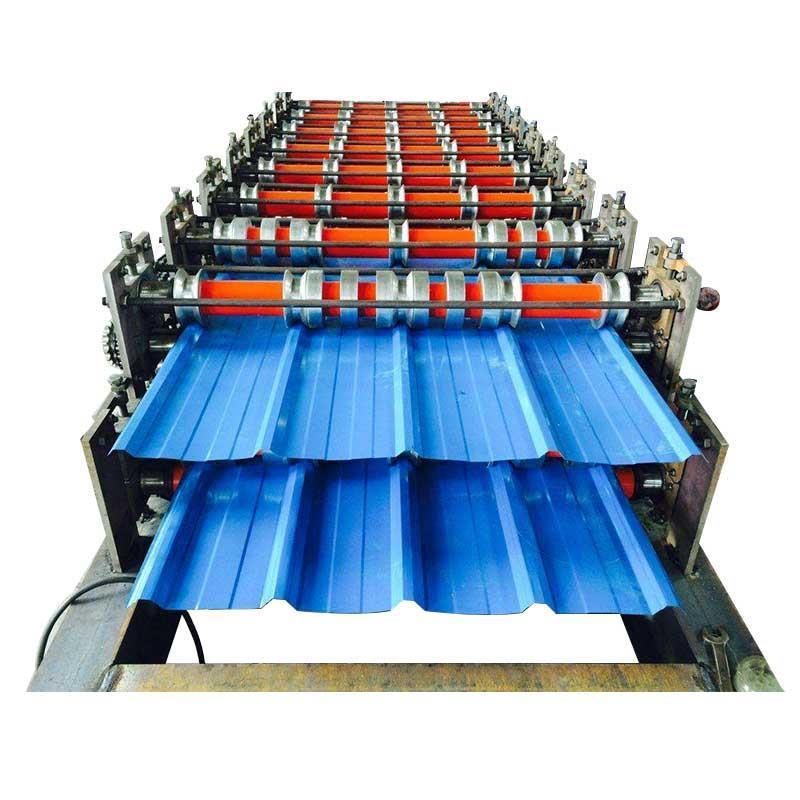

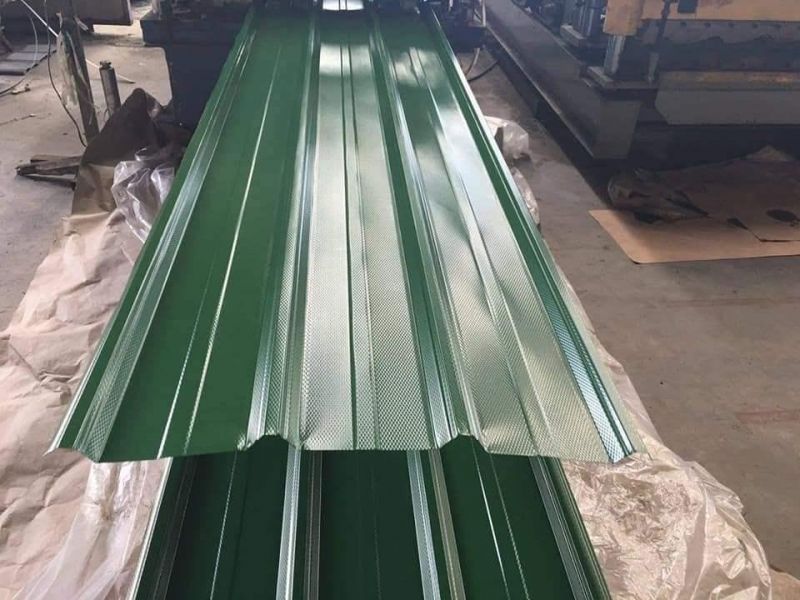

Effective Metal Galvanized Roof Tile Sheet Roll Forming Machine

Shandong Hongze International Trade Co., Ltd.- Technique:Hot Rolled

- Composition:Stainless Steel Scrap

- Standard:AISI, ASTM, DIN, JIS, GB, BS

- Type:Steel Coil, Color Coated Steel Sheet

- Shape:C Channel

- Surface Treatment:Galvanized

Base Info

- Bearing:Standard

- Speed:12-18m,Min

- Electric Components:Delta , Siemens , Mitsubishi

- Thickness:0.13mm-1.2mm

- Loading Port:Port in China

- Back Paint:5-25um

- Chain:1.0inch

- Width Tolerance:+,-3mm

- Roller:45# High Grade Steel with Heat Treatment, Hard Chr

- Shaft:45# High Grade Steel, 80mm, Solid, with Keyway

- Processing Service:Bending, Welding, Decoiling, Cutting, Punching

- Forming Station:16,18,21 Rows, Exactly According to Profile Drawin

- Brand Name:Hongze

- Support Frame:350h Steel, 10mm

- Application:Container Plate

- Special Use:High-strength Steel Plate, Wear Resistant Steel, Silicon Steel, Cold Heading Steel, Free Cutting Steel, Mold Steel

- Model NO.:HZSTEEL Forming machine

- Cutting Blade:Cr12MOV, Quenched 58°-62°

- Transport Package:Sea Package

- Specification:according to requirement

- Trademark:Hongze

- Origin:China

- HS Code:72107000

- Production Capacity:50000tons,Year

Description

Overview

A: Yes. Our rich experienced technical team can draft the accurate profile drawing, provide the most suitable technical solution for your required roll forming machine.

Q2. How can we be assured that you will deliver us quality machine with spare parts ?

A: 1. Customers can come to our factory, or send the technical people to our factory for checking the quality.

2. We can send the technicians to the buyer's factory for the installation of the machine.

Q3. What's your payment terms and delivery time?

A: 30% as the deposit by T/T in advance, 70% as the balance payment by T/T after your inspect the machine well and before delivery. Of course your payment terms are acceptable. After we get down payment, we will arrange production. About 30-45 days for delivery.

Q4. Do you have after-sales support?

A: Yes, we are happy to provide advice and we also have skilled technicians available across the world.

Q5. Do you sell only standard machines?

A: No, most of our machines are customized according to customers specifications, also adopt top brand components.

Q6. What will you do if the machine is broken?

A: We provide 18 months free warranty and free technical support for the whole life of any machine. If the broken parts can't repair, we can send the new parts replace the broken parts freely, but you need pay the express cost by yourself. If it is beyond the warranty period, we can negotiate to solve the problem, and we supply the technical support for the whole life of the roll forming machine.

Q7. Can you be responsible for transport?

A: Yes, please tell me the destination port or address. we have rich experience in transporting.

Thanks for your viewing !

Sincerely looking forward to our better and further communication !

Your kind inquiry will be highly appreciated, warmly welcome contact us now !

Company Profile

Detailed Photos

FAQ

Q1. Can you manufacture the roll forming machine according to my profile drawing or picture of finished product ?

A: Yes. Our rich experienced technical team can draft the accurate profile drawing, provide the most suitable technical solution for your required roll forming machine.

Q2. How can we be assured that you will deliver us quality machine with spare parts ?

A: 1. Customers can come to our factory, or send the technical people to our factory for checking the quality.

2. We can send the technicians to the buyer's factory for the installation of the machine.

Q3. What's your payment terms and delivery time?

A: 30% as the deposit by T/T in advance, 70% as the balance payment by T/T after your inspect the machine well and before delivery. Of course your payment terms are acceptable. After we get down payment, we will arrange production. About 30-45 days for delivery.

Q4. Do you have after-sales support?

A: Yes, we are happy to provide advice and we also have skilled technicians available across the world.

Q5. Do you sell only standard machines?

A: No, most of our machines are customized according to customers specifications, also adopt top brand components.

Q6. What will you do if the machine is broken?

A: We provide 18 months free warranty and free technical support for the whole life of any machine. If the broken parts can't repair, we can send the new parts replace the broken parts freely, but you need pay the express cost by yourself. If it is beyond the warranty period, we can negotiate to solve the problem, and we supply the technical support for the whole life of the roll forming machine.

Q7. Can you be responsible for transport?

A: Yes, please tell me the destination port or address. we have rich experience in transporting.

Thanks for your viewing !

Sincerely looking forward to our better and further communication !

Your kind inquiry will be highly appreciated, warmly welcome contact us now !