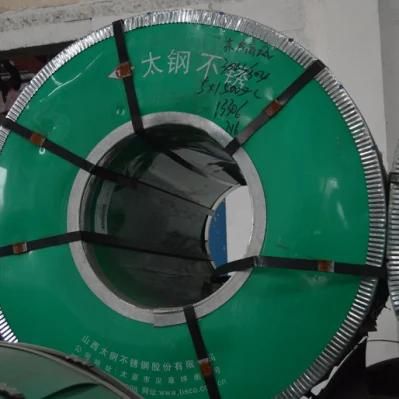

301 302 304 304L 316 Stainless Steel Coil for Kitchen Utensils Electric Equipment

WUXI BAOWANG STEEL CO., LTD.- Application:Ship Plate, Boiler Plate, Container Plate, Flange Plate, Architecture

- Technique:Cold Rolled

- Surface Treatment:Ba,2b,No.1,No.4,No.5,Hair Line,Embossed,Mirror

- Certification:ISO, IBR

- Type:Steel Coil

- Standard:ASTM, AISI, GB, JIS, DIN

Base Info

- Origin:Mainland China

- Transport Package:Standard Export Package or as Required

- Stock:Stock

- Special Use:High-strength Steel Plate, Wear Resistant Steel

- Model NO.:300 serials

- HS Code:7209179000

- Production Capacity:3000 Tons Per Month

Description

300series:301,302,304,304L,314,316,316L,309,310,310S

400series:409,409L,410,410S,420,430

0.15-0.25mm: +/-0.005mm

we usually use ASTM and GB Standard

Product Chemical compositionChemical Composition %

Finishings

| Surface Finish | Definition | Application |

| 2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

| BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

| HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

| NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe |