Q+T Alloy Steel Round Bar1.7225/SAE4140 for Machinery

HK JIMI STEEL CO., LTD.- Type:Carbon Steel Bar

- Standard:AISI, ASTM, DIN, JIS, GB, BS

- Composition:Alloy Steel

- Technique:Hot Rolled

- Shape:Flat

- Surface Treatment:Black Surface, Grinded, Rough Turned

Base Info

- Model NO.:4140,SCM440,42CrMo

- Special Use:Mold Steel

- Application:Tool Steel Bar

- Brand:HK Jimi Steel

- International Standard:AISI 4140,DIN 1.7225,JIS Scm440,GB 42CrMo

- Size:10~300mm*155~2200mm*2000~5000mm

- Steel Type:Alloy Steel,Alloy Structural Steel,4140,Scm440

- Test:SGS,Ut 100%,Element Testing

- Hardness:Annealed

- Delivery Condition:Hot Rolled,Cold Drawn,Forged,Eaf,ESR

- Status:Round Bars,Flats,Big Plates,Blocks

- Surface Require:Black,Grinding,Bright,Polish

- Tolerance of Size:-0,+5mm

- Features:High Hardenability&Toughness,Small Deformation

- Applications:Gear, Medium-Sized Shaft Parts, Piston

- Delivery:15 Days After Confirmed Contract

- Customized:Yes, OEM

- Trade Style:CIF,Fob,EXW,CFR

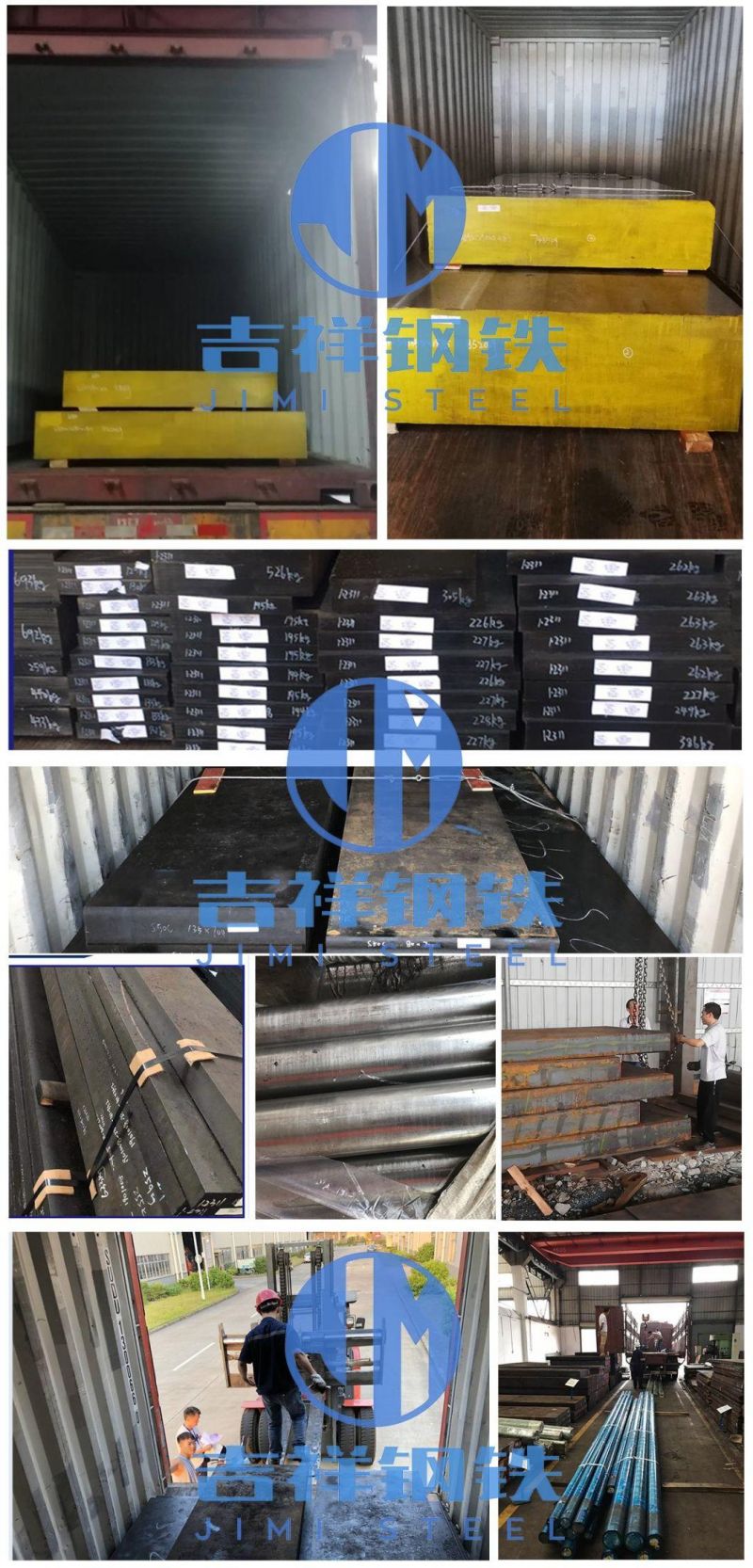

- Transport Package:Container

- Specification:20GP,40GP,40HQ

- Trademark:ISO9000,SGS

- Origin:China

- HS Code:7228

- Production Capacity:5000 Tons,Month

Description

Basic Info.

Model NO. 4140/SCM440/42CrMo Special Use Mold Steel Application Tool Steel Bar Brand HK Jimi Steel International Standard AISI 4140/DIN 1.7225/JIS Scm440/GB 42CrMo Size 10~300mm*155~2200mm*2000~5000mm Steel Type Alloy Steel/Alloy Structural Steel/4140/Scm440 Test SGS/Ut 100%/Element Testing Hardness Annealed Delivery Condition Hot Rolled/Cold Drawn/Forged/Eaf/ESR Status Round Bars/Flats/Big Plates/Blocks Surface Require Black/Grinding/Bright/Polish Tolerance of Size -0/+5mm Features High Hardenability&Toughness,Small Deformation Applications Gear, Medium-Sized Shaft Parts, Piston Delivery 15 Days After Confirmed Contract Customized Yes/ OEM Trade Style CIF/Fob/EXW/CFR Transport Package Container Specification 20GP/40GP/40HQ Trademark ISO9000/SGS Origin China HS Code 7228 Production Capacity 5000 Tons/MonthProduct Description

Alloy Steel Round Bar 1.7225/SAE4140 For Machinery Q+T

Product Introduction

AISI 4140 Steel Bar, Steel Plate, Flats Supplier, Stockist and Exporter. AISI SAE 4140 alloy steel is a chromium molybdenum alloy steel specification widely used in general purpose high tensile steel for components, like axles, shafts, bolts, gears and other applications. Similar to alloy grade AISI 4130 chrome moly alloy steel but with a slightly higher carbon content. The higher carbon content of AISI 4140 steel gives greater strength and heat treatment capabilities in comparison to AISI / ASTM 4130 alloy steels, however it does have inferior weldability characteristics.

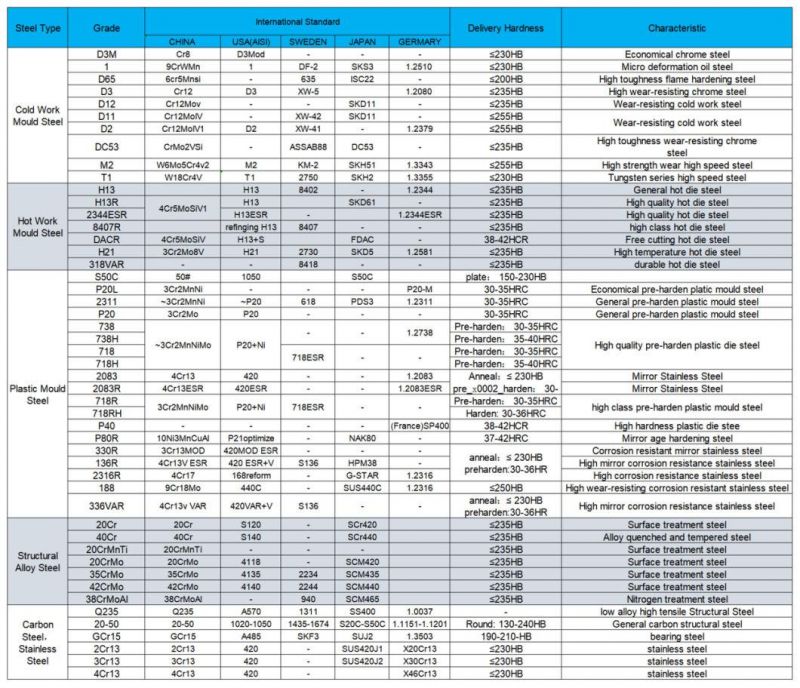

Equal Grades(numbers)

| Country | USA | German | British | Japan | China | Australia |

| Standard | ASTM A29 | DIN 17200 | BS 970 | JIS G4105 | GB/T 3077 | AS 1444 |

| Grades | 4140 | 1.7225/ 42crmo4 | 42CrMo4 | SCM440 | 42CrMo | 4140 |

Chemical Composition

| Standard | Grade | C | Mn | P | S | Si | Cr | Mo |

| ASTM A29 | 4140 | 0.38-0.43 | 0.75-1.00 | 0.035 | 0.040 | 0.15-0.35 | 0.8-1.10 | 0.15-0.25 |

| EN 10250 | 42CrMo4/ 1.7224 | 0.38-0.45 | 0.6-0.9 | 0.035 | 0.035 | 0.4 | 0.9-1.2 | 0.15-0.30 |

| JIS G4105 | SCM440 | 0.38-0.43 | 0.60-0.85 | 0.03 | 0.03 | 0.15-0.35 | 0.9-1.2 | 0.15-0.30 |

| Mechanical Properties | Metric | Imperial |

| Tensile strength | 655 MPa | 95000 psi |

| Yield strength | 415 MPa | 60200 psi |

| Bulk modulus (typical for steel) | 140 GPa | 20300 ksi |

| Shear modulus (typical for steel) | 80 GPa | 11600 ksi |

| Elastic modulus | 190-210 GPa | 27557-30458 ksi |

| Poisson's ratio | 0.27-0.30 | 0.27-0.30 |

| Elongation at break (in 50 mm) | 25.70% | 25.70% |

| Hardness, Brinell | 197 | 197 |

| Hardness, Knoop (converted from Brinell hardness) | 219 | 219 |

| Hardness, Rockwell B (converted from Brinell hardness) | 92 | 92 |

| Hardness, Rockwell C (converted from Brinell hardness. Value below normal HRC range, for comparison purposes only) | 13 | 13 |

| Hardness, Vickers (converted from Brinell hardness) | 207 | 207 |

| Machinability (based on AISI 1212 as 100 machinability) | 65 | 65 |

Forging

Preheat the steel carefully, heat to 1150 oC - 1200 oC maximum, hold until temperature is uniform throughout the section.

Do not forge below 850 oC.Following forging operation the work piece should be cooled as slowly as possible.

Heat Treatment

- Annealing

Heat ASTM 4140 steels to 800 oC - 850 oC, hold until temperature is uniform throughout the section and cool in furnace. - Normalizing

Heat steel alloy 4140 to 870 oC - 900 oC, hold until temperature is uniform throughout the section, soak for 10 - 15 minutes and cool in still air. - Tempering

Re-heat 4140 grade steel to 550 oC - 700 oC as required, hold until temperature is uniform throughout the section, soak for 1 hour per 25 mm of section, and cool in still air.

AISI alloy 4140 steel bar, plate and square can be hardened by cold working, or heating and quenching.

SAE 4140 alloy steel is usually supplied ready heat treated to hardness in 18-22 HRC. If further heat treatment is required, then heat to 840 oC - 875 oC, hold until temperature is uniform throughout the section, soak for 10 - 15 minutes per 25 mm section, and quench in oil, water, or polymer as required.

Application

ASTM alloy 4140 steel bar, flat or plate material can be used for as wide variety of applications where greater toughness and wear resistance is needed over lower carbon grades. Typical applications for 4140 tool steel uses include Components, Adapters, Arbors,strippers, holder blocks, mold bases, ejectors, back up and support tooling, fixtures, jigs, molds, cams, drill collars, Axle Shafts, Bolts, Crankshafts,stubs, couplings, reamer bodies, axles, shafting, piston rods, rams, hydraulic machinery shafts, gears, sprockets, gear racks, chain links, spindles, tool bodies, tool holders, tie rods, Connection Rods, Chuck Bodies, Collets, Conveyor Pins & Rolls, Ejector Pins, Forks, Gears, Guide Rods, Hydraulic Shafts & Parts,Lathe Spindles, Logging Parts, Milling Spindles, Motor Shafts, Nuts, Pinch Bars, Pinions, Pump Shafts,boring bars,tracks, slides, wear strips or parts, forming dies, brake dies, trim dies, bolsters, machinery parts and components, etc.

Welcome customers to inquiry AISI 4140 steel bar, plate, flat steel for the 4140 steel price. We are professional supplier and exporter for more than 20 years. We offer you worldwide solution for aisi alloy 4140 steel bar.

Available Sizes in Stock

| Steel Grade | Diameter(mm) | Length(mm) | Harness(HRC) |

| SCM440/SAE4140 | 16,18,20,23,25,28,30,33,35,38,40,43,45,48,50, 55,60,65,70,75,80,85,90,95,100,110,120,130,140, 150,160,170,180,190,200,210,220,230,240,250,260, 270,280,290,300,310,320,330,340,350,360,370,380, 390,400,410,420,430,440,450 | 4000-10000 | HB160-220 |

More Picutres

Workshop

About us :

HK JIMI STEEL Was established in 2012, located in the Shunde District of Guangdong Province, It is an import and export trading company mainly engaged in advanced special steel, die steel, alloy steel, and steel processing general machinery and equipment. The company adheres to the concept of "high quality, high requirements and good faith",

Cooperating with more than 20 famous steel mills in China, rich in spot stock of products.

Our company has a variety of processing equipment and all kinds of inspection and testing equipment, such as horizontal sawing machine, vertical sawing machine, milling machine, bilateral milling machine, precision milling machine, plane grinder and so on. The products with short producing time, excellent quality and high precision can provide a high-quality product choice for the vast number of customers at home and abroad.

Our customer group spread all over the domestic provinces and cities, abroad including Europe, the United States, Australia, the Middle East, Southeast Asia and other more than 20 countries and regions, along with over 100 long-term stable cooperation customers...Choosing Xingxiong will bring you a better experience.

PLASTIC MOULD STEEL: 1.2311, 1.2312, 1.2738, P20, 1.2083, 1.2316, NAK80, P40, 1.2738HH

HOT WORK MOULD STEEL: 1.2344, SKD61, H13, H11, FDAC, 8407

COLD WORL MOULD STEEL: SKD11, D3, SKS3, 1.2080, 1.2379, CR12MOV, O1, D2

STRUCTURAL ALLOY STEEL: 4140, 20CR, 40Cr, 35CrMo, 42CrMo, 38CrmoAi, SCM440, SCM420, 1.7225

CARBON STEEL &: Q235, Gcr15, S45C, S50C, S55C

CNC surface grinding machine, CNC side boring machine, Band saw, CNC double head machine, Vertical Band saw, CNC milling machine, Double alloy saw blade, wireless remote control crane, Magnetic chuck.

Our Service:

A. Steel plates: Cutting by bandsaw machine, milling, heat treatment, etc

B. Round bars: Cutting by bandsaw machine, peeling, grinding and turned, heat treatment, etc

Stock:

High-quality stock for various steel flat bar and round bar.

Alloy steel / Cold work steel / Hot work steel / Plactic mold steel and Stainless

Hot sales grade : DC53/ H13 / P20 / SCM440 / Q235,etc.

For more tool and die steel please check the list:

Delivery Time

1) For abundant stock, 7-15 days.

2) For customized products, 15-30 days.

Loading Details:

FAQ:

Q1: What do you do for the control of the quality?

A1: Before loading into the container, our products will all be inspected by ultrasonic inspection. Quality Grade conforms to SEP 1921-84 E/e, D/d, C/c as per customer's request.

Q2:: What are your hot-selling products?

A2: D2/1.2379, H13/1.2344, CR12MOV, DC53, CR8, abundant stock for both plates and rounds. Competitive prices and short lead-time.

Q3: Can we visit your company and factory?

A3: Yes, warmly welcome! We can book the hotel for you before you come to China and arrange our driver to our airport to pick you up when you come.

Q4: Are you a manufacturer or merely a trader?

A4: We are a group of companies and owned manufacturer bases and trading companies. We specialized in plastic mold steel, hot work mold steel, cold work mold steel, alloy steel for mechanical, high-speed steel, etc. All materials are of high quality and competitive prices.

Hot sales Product:

1.2344 SKD11 D3 DC50