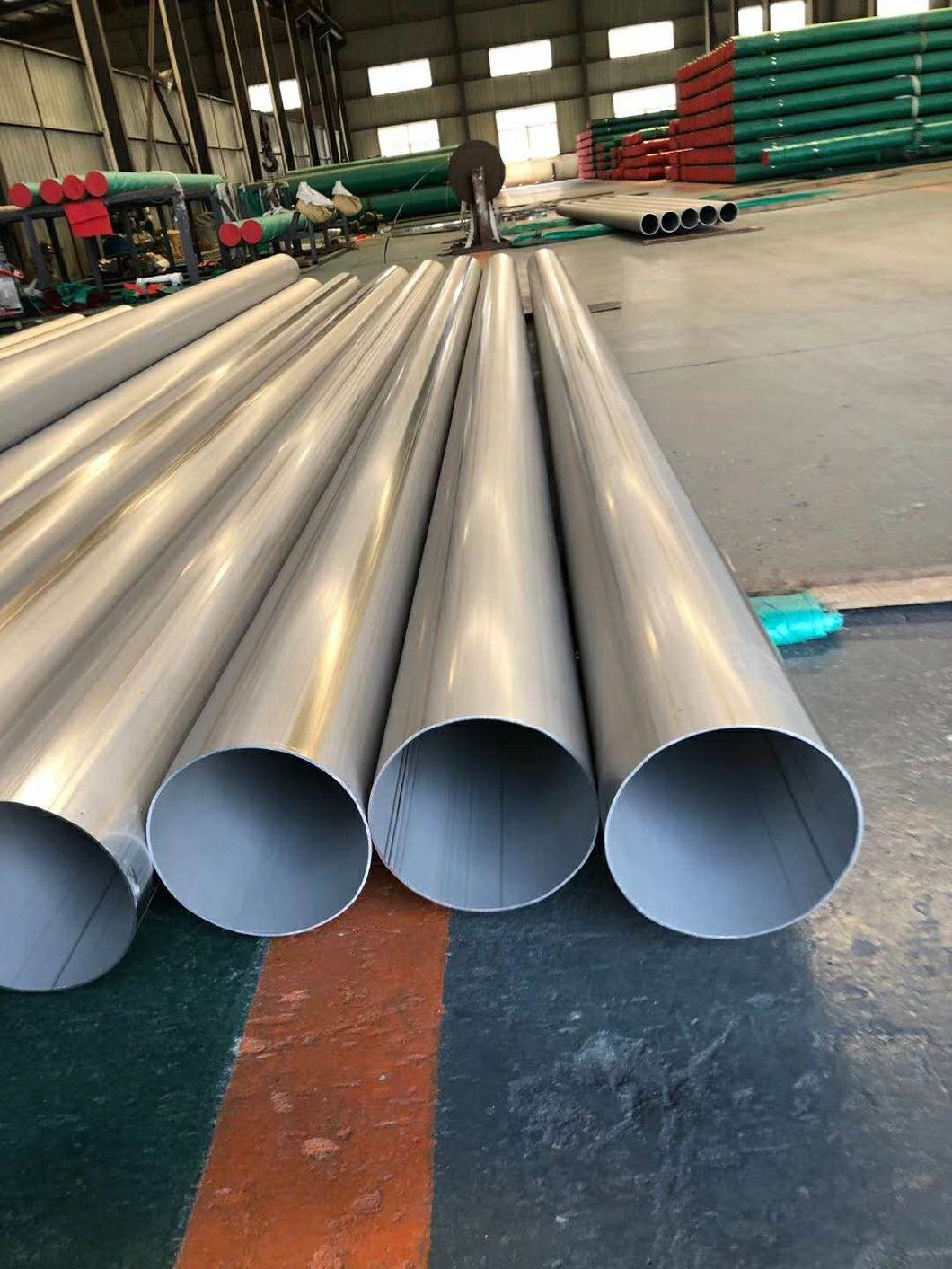

ASTM 316ln/ SUS316ln/ 1.4429 Seamless Stainless Steel Pipe (SS ASTM S31653/ EN X2CrNiMoN17-13-3) Seamless Pipe

Wuxi City Ge Ming Sheng Steel Trading Co., Ltd- Certification:AISI, ASTM

- Grade:300 Series

- Standard:AISI, JIS

- Type:Stainless Steel Pipes

- Shape:Round

- Technique:Cold-Drawing

Base Info

- Origin:China

- Specification:OD 6-630mm

- Transport Package:Wooden Box

- Surface Treatment:Polished

- Model NO.:316LN

- HS Code:7304319000

- Production Capacity:500000kgs

Description

304/SUS304/UNS S30400/1.4301

304L/UNS S30403/1.4306;

304H/UNS S30409/1.4948;

309S/UNS S30908/1.4833

309H/UNS S30909;

310S/UNS S31008/1.4845;

310H/UNS S31009;

316/UNS S31600/1.4401;

316Ti/UNS S31635/1.4571;

316H/UNS S31609/1.4436;

316L/UNS S31603/1.4404;

316LN/UNS S31653;

317/UNS S31700;

317L/UNS S31703/1.4438;

321/UNS S32100/1.4541;

321H/UNS S32109;

347/UNS S34700/1.4550;

347H/UNS S34709/1.4912;

348/UNS S34800;

ASTM A234 WP5/WP9/WP11/WP12/WP22/WP91;

ASTM A860 WPHY42/WPHY52/WPHY60/WPHY65;

ASTM A420 WPL3/WPL6/WPL9;

ASTM A182 F51/S31803/1.4462;

ASTM A182 F53/S2507/S32750/1.4401;

ASTM A182 F55/S32760/1.4501/Zeron 100;

2205/F60/S32205;

ASTM A182 F44/S31254/254SMO/1.4547;

17-4PH/S17400/1.4542/SUS630/AISI630;

F904L/NO8904/1.4539;

725LN/310MoLN/S31050/1.4466

253MA/S30815/1.4835;

Alloy 200/Nickel 200/NO2200/2.4066/ASTM B366 WPN;

Alloy 201/Nickel 201/NO2201/2.4068/ASTM B366 WPNL;

Alloy 400/Monel 400/NO4400/NS111/2.4360/ASTM B366 WPNC;

Alloy K-500/Monel K-500/NO5500/2.475;

Alloy 600/Inconel 600/NO6600/NS333/2.4816;

Alloy 601/Inconel 601/NO6001/2.4851;

Alloy 625/Inconel 625/NO6625/NS336/2.4856;

Alloy 718/Inconel 718/NO7718/GH169/GH4169/2.4668;

Alloy 800/Incoloy 800/NO8800/1.4876;

Alloy 800H/Incoloy 800H/NO8810/1.4958;

Alloy 800HT/Incoloy 800HT/NO8811/1.4959;

Alloy 825/Incoloy 825/NO8825/2.4858/NS142;

Alloy 925/Incoloy 925/NO9925;

Hastelloy C/Alloy C/NO6003/2.4869/NS333;

Alloy C-276/Hastelloy C-276/N10276/2.4819;

Alloy C-4/Hastelloy C-4/NO6455/NS335/2.4610;

Alloy C-22/Hastelloy C-22/NO6022/2.4602;

Alloy C-2000/Hastelloy C-2000/NO6200/2.4675;

Alloy B/Hastelloy B/NS321/N10001;

Alloy B-2/Hastelloy B-2/N10665/NS322/2.4617;

Alloy B-3/Hastelloy B-3/N10675/2.4600;

Alloy X/Hastelloy X/NO6002/2.4665;

Alloy G-30/Hastelloy G-30/NO6030/2.4603;

Alloy X-750/Inconel X-750/NO7750/GH145/2.4669;

Alloy 20/Carpenter 20Cb3/NO8020/NS312/2.4660;

Alloy 31/NO8031/1.4562;

Alloy 901/NO9901/1.4898;

Incoloy 25-6Mo/NO8926/1.4529/Incoloy 926/Alloy 926;

Inconel 783/UNS R30783;

NAS 254NM/NO8367;

Monel 30C

Nimonic 80A/Nickel Alloy 80a/UNS N07080/NA20/2.4631/2.4952

Nimonic 263/NO7263

Nimonic 90/UNS NO7090;

Incoloy 907/GH907;

Nitronic 60/Alloy 218/UNS S21800

5.balance 6.PHYSICAL PROPERTIES 8.00 0.289 g/cm³ Lb/in³ 8.4 14.6 BTU/hr·ft·°F W/m·K Thermal Expansion Coefficient at 68-212°F(20-100ºC) 9.2 16.5 μ in/in/°F μ m/m/°C Thermal Expansion Coefficient at 68-932°F(20-500ºC) 10.1 18.2 μ in/in/°F μ m/m/°C Thermal Expansion Coefficient at 68-1832°F(20-1000ºC) 10.8 19.5 μ in/in/°F μ m/m/°C Available Tube Product form Straight Coiled Seamless Typical Applications Orthopaedic implants Trauma nails Neurological applications Surgical instruments Industries predominantly using this Grade Chemical processing High performance liquid chromatography (hplc) Medical 316LN stainless is a single phase austenitic (face centered cubic) stainless steel at all temperatures up to the melting point. The alloy can not be hardened by heat treatment. The alloy is nonmagnetic in the annealed condition. Its magnetic permeability is typically less than 1.02 at 200 H (Oersteds). Permeability values for cold de-formed material vary with composition and the amount of cold deformation, but are usually higher than that for annealed material. 7.MECHANICAL PROPERTIES Typical Room Temperature properties 30 ksi* 205 MPa* 75 ksi* 515 MPa* * minimum, ** maximum Fatigue Resistance The fatigue strength or endurance limit is the maximum stress below which a material is unlikely to fail in 10 million cycles in an air environment. For austenitic stainless steels as a group, the fatigue strength is typically about 35 percent of the tensile strength. However, substantial variability in service results is experienced since additional variables such as corrosive conditions, type of loading and mean stress, surface condition, and other factors affect fatigue properties. For this reason, no definitive endurance limit value can be given which is representative of all operating conditions. Product pictureProperty Value Units Density at 72°F(22ºC) Melting Range 2450°F-2630°F 1345ºC-1440ºC Thermal Conductivity at 212°F(100ºC) Property ASTM A 240 Yield Strength, 0.2% offset Ultimate Tensile Strength Elongation in 2" (51 mm) 40%* Hardness 217 Brinell** 95 HRB**