China Manufacturer Ral7016 Nippon Painting Dx51d PPGI/Prepainted Gi Steel Coil

Shandong Wanhui Iron & Steel Sales Co., Ltd.- Surface Treatment:Galvanized

- Certification:ISO, RoHS, IBR

- Standard:ASTM, JIS, GB, AISI, DIN, BS

- Warranty:Quality Assurance

- After-sales Service:Guarantee

- Technique:Cold Rolled

Base Info

- Transport Package:Standard Export Packing

- Delivery Time:7-5days

- Surface:2b,Ba,No.1,No.4,Hi,8K,6K

- Thickness:0.13-2.5mm

- Width:600mm to 1500mm

- Material Grade:SPCC,Spcd,Spce,St12-15,DC01-06,Q195A-Q235A,Q195af-

- Stock:Stock

- Edge:Slit edge

- Application:Container Plate

- Specification:Customized Size

- Trademark:Tisco, Liscl, Bao Steel

- Origin:China

- Production Capacity:6000tons, Month

Description

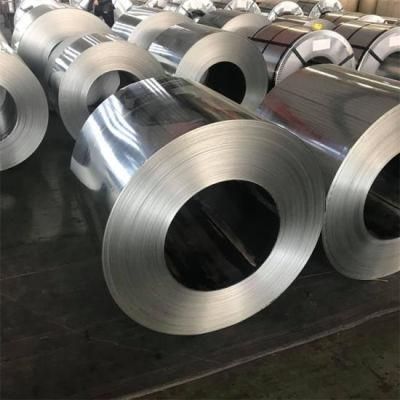

Hot Dipped Galvanized Steel Sheet in Coil (GI) is produced by passing the Full Hard sheet which has undergone the acid washing process and rolling process through the zinc pot, thereby applying zinc film to the surface. It has excellent corrosion resistance, paintability, and workability due to Zinc's characteristics. Usually, hot-dipped galvanized steel sheet and galvanized steel coil process and specifications are basically the same.

Hot Dipped Galvanized Steel Sheet in Coil (GI) is produced by passing the Full Hard sheet which has undergone the acid washing process and rolling process through the zinc pot, thereby applying zinc film to the surface. It has excellent corrosion resistance, paintability, and workability due to Zinc's characteristics. Usually, hot-dipped galvanized steel sheet and galvanized steel coil process and specifications are basically the same.Hot-dip galvanizing is the process of applying a protective zinc coating to a steel sheet or iron sheet, to prevent rusting.

Excellent anti-corrosion, paintability, and processability due to the self-sacrificing characteristic of zinc.

Available to select and produce the desired amount of zinc gilded and in particular enables thick zinc layers(maximum 120g/m2).

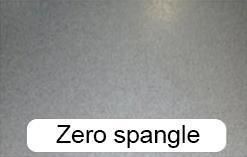

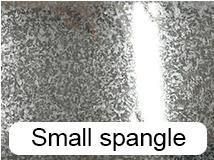

Classified as either zero spangle or extra smooth depending on whether the sheet undergoes skin pass treatment.

Product Parameters

Shandong Wanhui Iron & Steel Sales Co.Ltd. is located in Shandong, with superior geographical location and convenient transportation. It is a company engaged in aluminum coil, aluminum plate, aluminum strip, aluminum tube, aluminum profile, aluminum foil, aluminum wafer stainless steel plate, stainless steel coil, stainless steel strip, stainless steel tube, stainless steel profile,copper plate, copper coil, copper tube and lead plate. The company is a comprehensive enterprise integrating warehousing, processing, and trade distribution. We have complete specifications and abundant kind of products. Various processing services can be provided according to customer requirements such as slitting and drawing, mirror, oil grinding, polishing, punching, bending, leveling, slitting, laser cutting, rolling, punching, threading cutting, milling, turning, drilling, material customization and etc. The company has more than 60 advanced processing and testing equipment, nearly 1,000 tons of materials in stock, and more than 200 kinds of products for management and agency. Our company is market-oriented and provides customized services to customers. Pursuing excellence and striving for first-class is our unremitting pursuit.

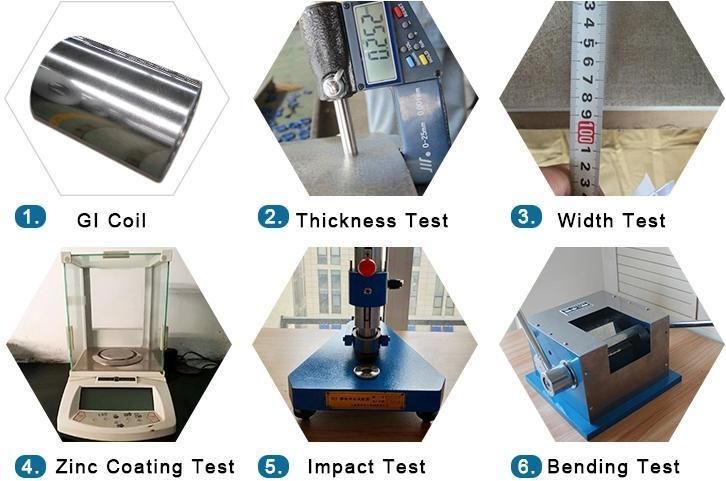

Quality Inspection

Packing&Shipping

FAQ

Q1. How long can make delivery?

A: For stock products,will make shipments in 2-5 days after receiving deposit or receiving T/T;

for products need new production for common materials,usually make shipments in 7-10 days;

for products need new special and rare materials,usually need 15-20 days to make shipment.

Q2. Can you provide samples?

A: The buyer will pay for the samples and postage

Q3. What's your payment terms?

A: Down payments 30%TT and balance 70% TT or L/C.

Q4. How do you ship the goods and how long does it take to arrive?

A: We usually ship by DHL, UPS or FedEx. It usually takes 3-5 days to arrive.

Airline and sea shipping also optional.

For mass products, ship freight is prefered.

Q5. Can you accept customize?

A: Yes. It can be customized as per the customers' request

Q6. How to ensure the quality?

A:Mill Test Certificate is supplied with shipment.

If needed, a Third Party Inspection is acceptable or SGS.

Otherwise, we can provide you free samples to test our quality.

Certifications