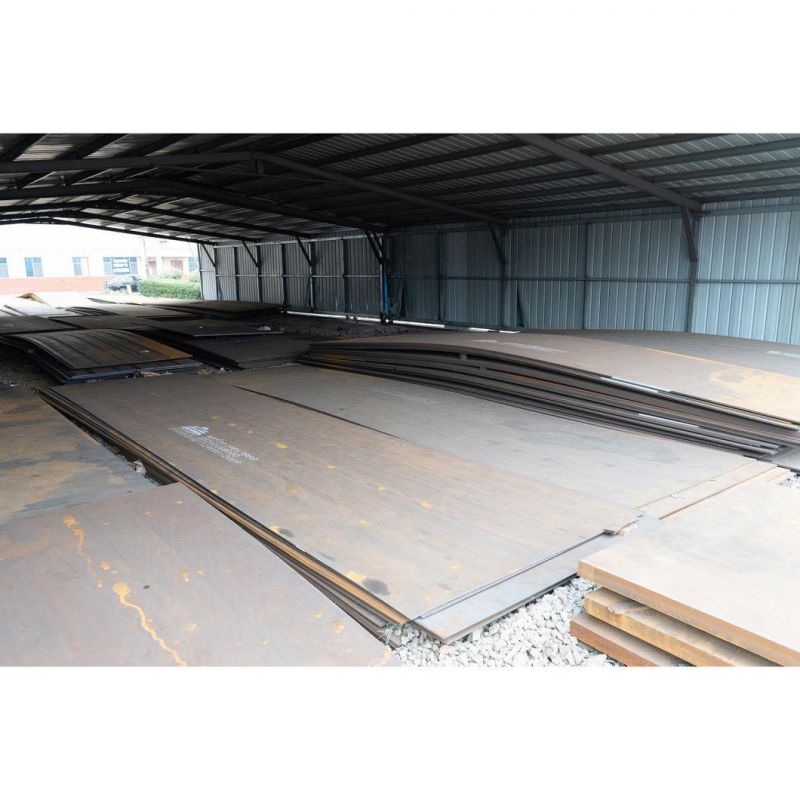

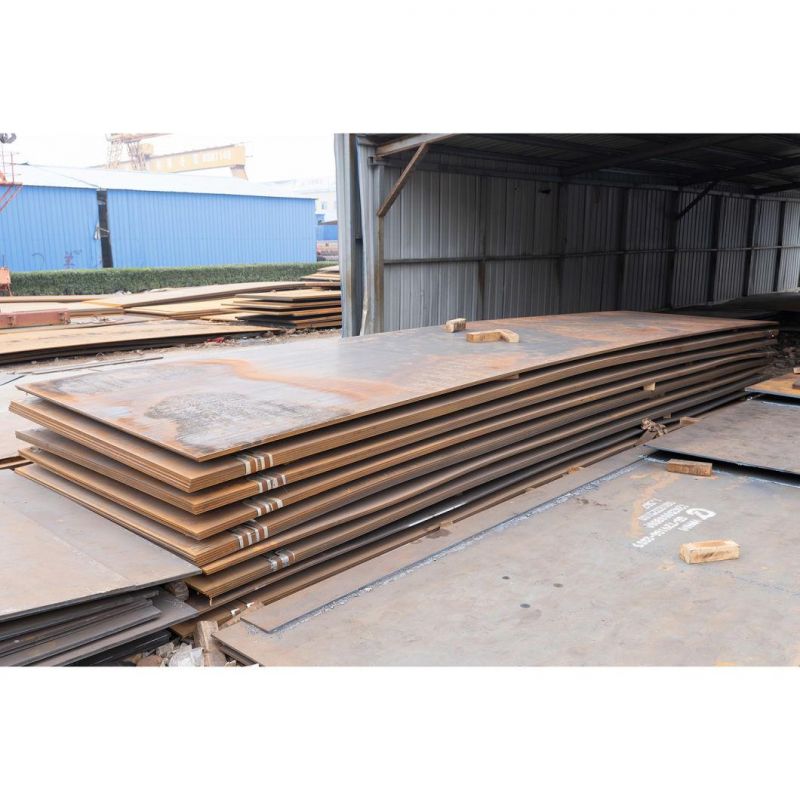

Carbon Alloy High Strength Steel Plate Cutting by Laser Machine

Shandong Zayi Steel Co., Ltd- Standard:ASTM, AISI, GB, JIS, DIN, BS

- Type:Steel Plate

- Warranty:3 Years

- After-sales Service:Always

- Certification:ISO, RoHS, IBR

- Surface Treatment:Blackface

Base Info

- Other Type 1:Engineering Steel, Cold Work Tool Steel

- Test:Ensile Strength, Yield Strength, Elongation

- Ex-Stock:Yes

- Service:24 Hours on Line

- Other Type:Engineering Steel, Cold Work Tool Steel

- Usage:Automotive, Aerospace, Power Generation, Oil & Gas

- Technology:Hot Rolled, Forged, Cold Drawn

- Process:Eaf+Lf+Vd+Forged+Heat Treatment(Optional)

- Grain Size:ASTM E112

- Non-Metallic Inclusiton:ASTM E45

- Length:3000-5800mm

- Heat Treatment:Annealed

- Stock:Stock

- Special Use:Cutting Tools, Measuring Tools, Cutters in Common Steel, High-strength Steel Plate, Wear Resistant Steel, Silicon Steel

- Application:Mold & Dies, Ship Plate, Boiler Plate, Container Plate, Flange Plate

- Technique:Hot Rolled

- Model NO.:steel plate cutting

- Other Type 2:Hot Work Tool Steel, Plastic Mold Steel

- Other Type 3:Spring Steel, High Speed Steel, Stainless Steel

- Other Type 4:Mold Steel, Free Cutting Steel, Cold Heading Steel

- Transport Package:Seaworthy Package

- Specification:1-150mm

- Trademark:zayi

- Origin:China

- HS Code:72284000

- Production Capacity:48000tons,Month

Description

Basic Info.

Model NO. steel plate cutting Technique Hot Rolled Application Mold & Dies, Ship Plate, Boiler Plate, Container Plate, Flange Plate Special Use Cutting Tools, Measuring Tools, Cutters in Common Steel, High-strength Steel Plate, Wear Resistant Steel, Silicon Steel Stock Stock Heat Treatment Annealed Length 3000-5800mm Non-Metallic Inclusiton ASTM E45 Grain Size ASTM E112 Process Eaf+Lf+Vd+Forged+Heat Treatment(Optional) Technology Hot Rolled/ Forged/ Cold Drawn Usage Automotive, Aerospace, Power Generation, Oil & Gas Ex-Stock Yes Service 24 Hours on Line Other Type Engineering Steel, Cold Work Tool Steel Test Ensile Strength, Yield Strength, Elongation Other Type 1 Engineering Steel, Cold Work Tool Steel Other Type 2 Hot Work Tool Steel, Plastic Mold Steel Other Type 3 Spring Steel, High Speed Steel, Stainless Steel Other Type 4 Mold Steel, Free Cutting Steel, Cold Heading Steel Transport Package Seaworthy Package Specification 1-150mm Trademark zayi Origin China HS Code 72284000 Production Capacity 48000tons/MonthProduct Description

Steel Plate Alloy Steel Tool Steel Die Steel Mould Steel High Strength Steel Wear Resistance Steel Corten Steel Carbon Steel Plate1.Carbon Steel Plate

Carbon steel plate usually been considered as the steel that does not contain much alloy steel elements. Generally elements are C, Mn, P, S, Si, besides these there are no minimum limits for elements of Al, Cr, Ni, Mo, V etc.

Carbon steel plates are available in different grades depending on the carbon content and strength.

There are low, medium, and high carbon steel plates. The more carbon content, the more durable and stronger the plate becomes. There are further sub-categories depending on thickness and usage as well as the formation process. Usually carbon steel plates vary from 0.4 mm to 80 mm in thickness and 1000 mm to 25000 mm width, and they can be of length up to 12 meters. But the length is customizable which helps the customers to put them into various applications. One can also make cold rolled steel coils from them.

2.Alloy Steel plate----42CrMo4 alloy steel plate

Chemical composition % of steel 42CrMo4 (1.7225): EN 10083-3-2006

| C | Si | Mn | P | S | Cr | Mo |

| 0.38 - 0.45 | max 0.4 | 0.6 - 0.9 | max 0.025 | max 0.035 | 0.9 - 1.2 | 0.15 - 0.3 |

Mechanical properties of steel 42CrMo4 (1.7225)

| Nominal diameter (mm): | to 16 | 16 - 40 | 40 - 100 | 100 - 160 | 160 - 250 | 250 - 330 | 330 - 660 |

| Rm - Tensile strength (MPa) (+QT) | 1100-1300 | 1000-1200 | 900-1100 | 800-950 | 750-900 | 700 | 600 |

| Nominal thickness (mm): | 0.3 - 3 |

| Rm - Tensile strength (MPa) (+A) | 620 |

| Rm - Tensile strength (MPa) (+AC) | 630 |

| Nominal thickness (mm): | to 8 | 8 - 20 | 20 - 50 | 50 - 80 |

| Rm - Tensile strength (MPa) (+QT) | 1100 | 1000 | 900 | 800 |

| Rm - Tensile strength (MPa) (+C) | 720 |

| Rm - Tensile strength (MPa) (+LC) | 670 |

| Nominal diameter(mm): or for flat products thickness: to 8; 8-20; 20-60; 60-100; 100-160; | to 16 | 16 - 40 | 40 - 100 | 100 - 160 | 160 - 330 | 330 - 660 |

| Re - Upper yield strength or Rp0.2 - 0.2% proof strength (MPa) (+QT) | 900 | 750 | 650 | 500-550 | 460-500 | 390 |

| Nominal thickness(mm): | 0.3 - 3 |

| Rp0.2 0.2% proof strength (MPa) (+A) | 480 |

| KV - Impact energy (J) longitud., (+QT) | +20° 30-35 |

| KV - Impact energy (J) transverse, (+QT) | +20° 22 |

| Nominal thickness (mm): | 0.3 - 3 |

| A - Min. elongation Lo = 80 mm (%) (+A) | 15 |

| A - Min. elongation at fracture (%) transverse, (+QT) | 10-14 |

| A - Min. elongation at fracture (%) (+C) | 4 |

| A - Min. elongation at fracture (%) (+LC) | 6 |

| Nominal thickness (mm): | to 16 | 16 - 40 | 40 - 100 | 100 - 160 | 160 - 250 |

| A - Min. elongation Lo = 5,65 √ So (%) (+QT), round products | 10 | 11 | 12 | 13 | 14 |

| Nominal diameter (mm): or for flat products thickness: to 8; 8-20; 20-60; 60-100; 100-160; | to 16 | 16 - 40 | 40 - 100 | 100 - 160 | 160 - 250 |

| Z - Reduction in cross section on fracture (%) (+QT) | 40 | 45 | 50 | 50 | 55 |

| Z - Reduction in cross section on fracture (%) (+AC) | 57 |

| Brinell hardness (HBW): (+S) | 255 |

| Brinell hardness (HBW): (+A) | 241 |

| Vickers hardness ( HV): (+A) | 195 |

| Vickers hardness ( HV): (+QT) | 340 - 490 |

| Weldability: Bad weldability due to the high crack danger. Hardenability: Medium-good hardenability, suitable for hot purposes till a temperature of 500 C. It can be hardened in oil. |

3.wear resistant steel plate

wear resistant steel plate is a high-carbon alloy steel designed specifically to have greater hardness properties than low-carbon steel.

Hardness typically comes at the expense of strength, making AR wear-resistant steel an ideal material for harsh, high-abrasion conditions, and not for structural applications.

Material:

Sweden :Hardox 400 wear resistant steel plate,Hardox 450 wear resistant steel plate,Hardox 500 wear resistant steel plate,Hardox 550 wear resistant steel plate,Hardox 600 wear resistant steel plate.

Germany:XAR 400 wear resistant steel plate,XAR 300 wear resistant steel plate,XAR 500 wear resistant steel plate

Dillidur400 wear resistant steel plate,Dillidur 500 wear resistant steel plate,

Frace:Creusabro4800 wear resistant steel plate,Creusabro 8000 wear resistant steel plate

4.high strength steel plate

High-strength steel plate (high-strength plate) has high strength, especially in the normalizing or normalizing and tempering state, it has higher comprehensive mechanical properties. Mainly used for large ships, bridges, power station equipment, medium and high pressure boilers, high pressure vessels, rolling stock, hoisting machinery, mining machinery and other large welded structural parts.

| 1.8904 S550Q | 1.8906 S460QL |

| 1.8908 S460Q | 1.8909 S500QL |

| 1.8914 S620Q | 1.8916 S460QL1 |

| 1.8924 S500Q | 1.8925 S890QL1 |

| 1.8926 S550QL | 1.8927 S620QL |

| 1.8928 S690QL | 1.8931 S690Q |

| 1.8933 S960QL | 1.8940 S890Q |

| 1.8941 S960Q | 1.8983 S890QL |

| 1.8984 S500QL1 | 1.8986 S550QL1 |

| 1.8987 S620QL1 | 1.8988 S690QL1 |

5.Corten steel plate

Weathering steel, often referred to by the genericised trademark COR-TEN steel and sometimes written without the hyphen as corten steel, is a group of steel alloys which were developed to eliminate the need for painting, and form a stable rust-like appearance after several years' exposure to weather.

U.S. Steel holds the registered trademark on the name COR-TEN. The name COR-TEN refers to the two distinguishing properties of this type of steel: corrosion resistance and tensile strength.Although USS sold its discrete plate business to International Steel Group (now ArcelorMittal) in 2003, it still sells COR-TEN branded material in strip-mill plate and sheet forms.

The original COR-TEN received the standard designation A242 (COR-TEN A) from the ASTM International standards group. Newer ASTM grades are A588 (COR-TEN B) and A606 for thin sheet. All alloys are in common production and use.

The surface oxidation of weathering steel takes six months, but surface treatments can accelerate the oxidation to as little as two hours

F A Q

1. How can I know whether you are a reliable company?

We are engaged in steel plate over 10 years and have high visibility in domestic. We welcome you to inspect our company at any time.

2. Can you guarantee your products?

Yes, we guarantee your 100% satisfaction on all our products. Please feel free to feedback us immediately.

3. Do you provide samples?

Yes, we can provide most of the product samples. We will charge a little sample fee. But we will return the charge if you place an order. if you asked to use DHL, Blue Dart Express, FedEx, etc. to send samples, you can inform us in advance to prepare.

4. Can I visit your company?

Of course, If you want to order our products and visit our company, please contact us to make an appointment.

5. Can you make boxes according to my request ?

Yes,customization service is available,OEM business is appreciated.

When you place the orders,we arrange the production asap,When finish the orders, we will inform you and also we arrange the shipping in the same time.

6. How much is the freight?

It depends on the number and transport methods. When asked about the freight, we want you to let us know your detailed information , such as the product name and quantity and your favorite mode of transport, as well as your designated port or airport. We thank you for providing us the information to estimate the cost.