800 800h 800ht Incoloy Alloy Round Bar

Dongtai Zhonghai Super Alloy Co., Ltd.- Shape:Bar

- Technique:Cold Drawn

- Composition:Nickel Alloy

- Standard:ASTM, DIN, JIS, GB, BS

- Type:Round

- Surface Treatment:Polished

Base Info

- Transport Package:Wooden Box

- Supply Ability:500 Ton,Tons Per Month Incoloy 825

- Grade:Nickel Base Alloy, Incoloy 825

- Model Steel:Incoloy 825

- M.O.Q:300kg

- Application:Structural Steel Bar

- Special Use:Mold Steel

- Model NO.:incoloy 800

- Specification:φ 6-273mm; Length 1000-8000mm

- Trademark:ZHS

- Origin:Jiangsu, China

- HS Code:75051200

- Production Capacity:2000tons, Month

Description

Diameter Of Alloy barHot Rolled: Φ8-38mm Forging: Φ38-350mm Cold Rolled: ≤50mm Standard ASTM B574 ASTM B164 ASTM B166 ASTM B638 ASTM B408 Length As Required Surface Black or Bright Manufacture Technology Hot Rolled ,Forging , Cold Rolled Package wooden boxes package,pvc package, and other package

Incoloy 825 SpecificationAlloy% Ni Cr Fe C Mn Mn Cu Mo Al Ti P S Min 38 19.5 balance 1.5 2.5 1 0.6 825 Max 46 23.5 balance 0.05 1 0.5 3 3.5 0.2 1.2 0.02 0.03

Incoloy 825 Physical properties

Incoloy 825 Alloy mi nimum mechanical properties in the room temperature

Characteristic as below

1. Good stress corrosion cracking resistance performance

2. Good resistance for pitting and crevice corrosion performance

3. Good anti-oxidation and non-oxidzing heat acid performance

4. Good mechanical performance in both room temperature and up to 550°C

5. Have the pressure vessel authenticate when manufacture temperature up to 450°C

Incoloy 825 Metallurgical structure

825 is the face-centered cubic lattice structure.

Incoloy 825 Application field

825 widely use in many kinds of industry field that the working temperature no more than 550°C.

Incoloy 825 Typical application field

1. Sulfuric acid factory usage for heating pipe, container, basket, chain and so on.

2. Cooling heat exchanger, marine product pipeline system and gas pipeline of acidic environment.

3. Heat exchanger, steam machine, washing, impregnation pipe, etc. for phosphoric acid produce

4. Oil refining in the air heat exchanger

5. Food project

6. Chemical process

7. Application of high pressure oxygen flam-retardant alloy

Product showing.

Packing & delivery

Factory:

Quality Certificate: In order to improve the quality of products and services, with each order we provide a quality mtc for goods, which includes measured data - chemical composition, electrical resistivity, tensile strength, elongation, melting number, etc.

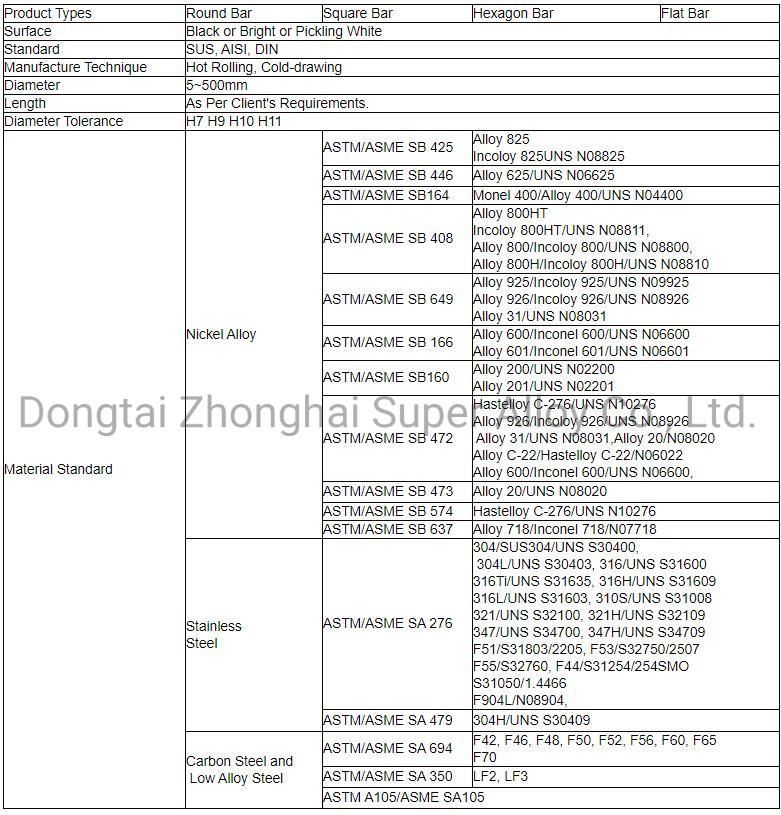

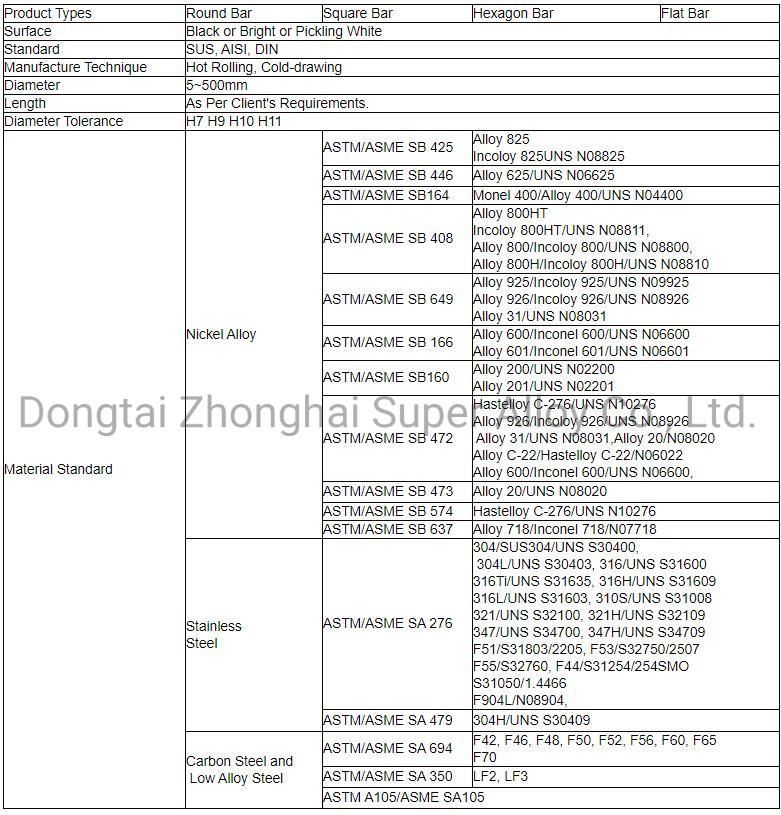

Material range:

Incoloy 825 SpecificationAlloy

Incoloy 825 Physical properties

| Density | 8.1 g/cm³ |

| Melting point | 1370-1400°C |

Incoloy 825 Alloy mi nimum mechanical properties in the room temperature

| Alloy state | Tensile strength Rm N/mm² | Yield strength R P0. 2N/mm² | Elongation A 5 % | Brinell hardness HB |

| 825 | 550 | 220 | 30 | ≤200 |

Characteristic as below

1. Good stress corrosion cracking resistance performance

2. Good resistance for pitting and crevice corrosion performance

3. Good anti-oxidation and non-oxidzing heat acid performance

4. Good mechanical performance in both room temperature and up to 550°C

5. Have the pressure vessel authenticate when manufacture temperature up to 450°C

Incoloy 825 Metallurgical structure

825 is the face-centered cubic lattice structure.

Incoloy 825 Application field

825 widely use in many kinds of industry field that the working temperature no more than 550°C.

Incoloy 825 Typical application field

1. Sulfuric acid factory usage for heating pipe, container, basket, chain and so on.

2. Cooling heat exchanger, marine product pipeline system and gas pipeline of acidic environment.

3. Heat exchanger, steam machine, washing, impregnation pipe, etc. for phosphoric acid produce

4. Oil refining in the air heat exchanger

5. Food project

6. Chemical process

7. Application of high pressure oxygen flam-retardant alloy

Product showing.

Packing & delivery

Factory:

Quality Certificate: In order to improve the quality of products and services, with each order we provide a quality mtc for goods, which includes measured data - chemical composition, electrical resistivity, tensile strength, elongation, melting number, etc.

Material range: