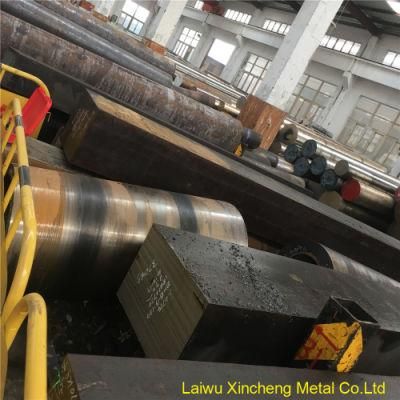

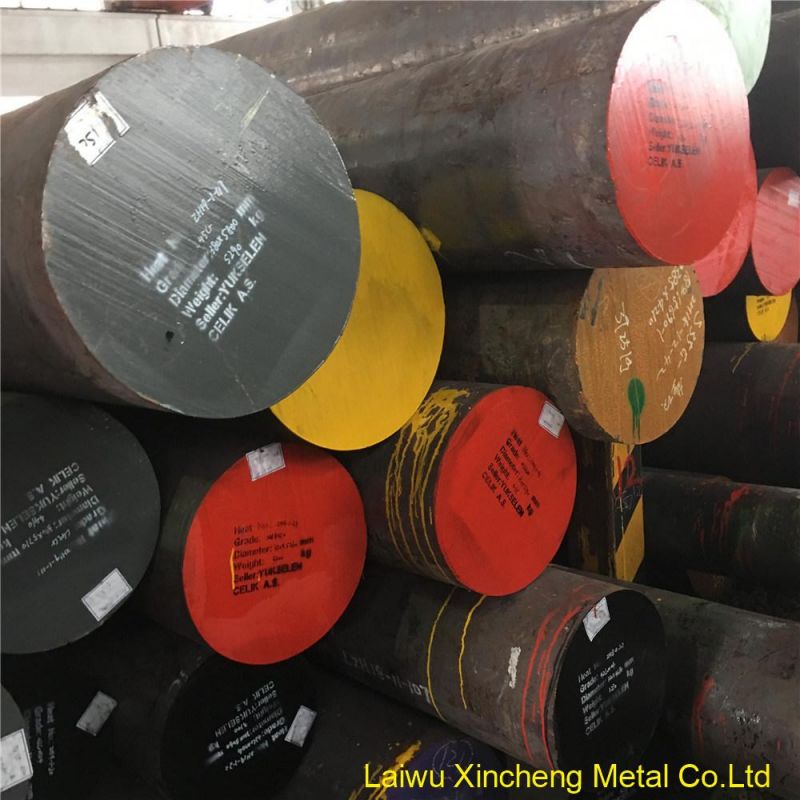

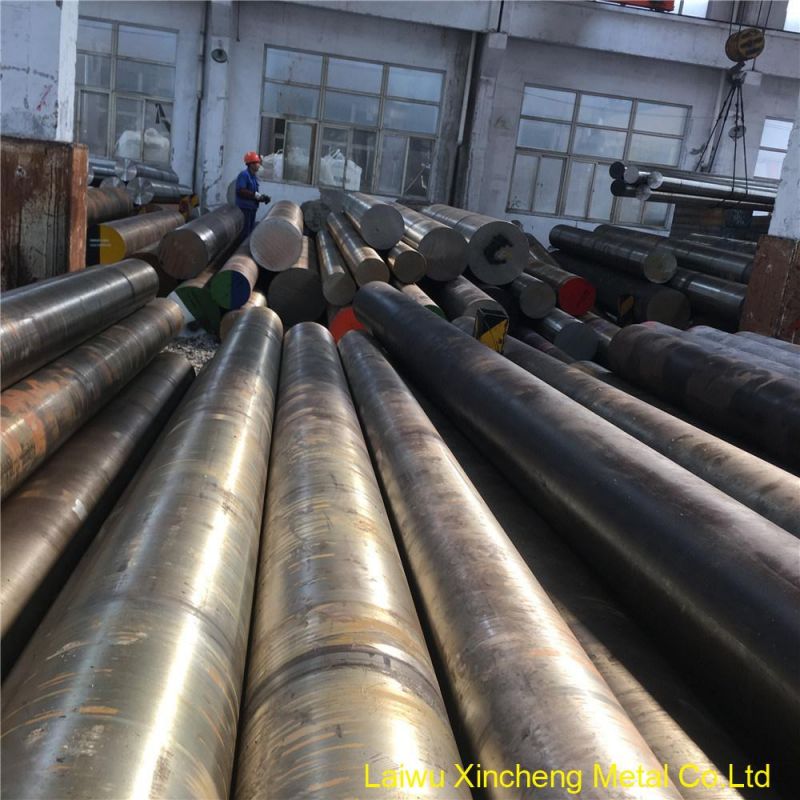

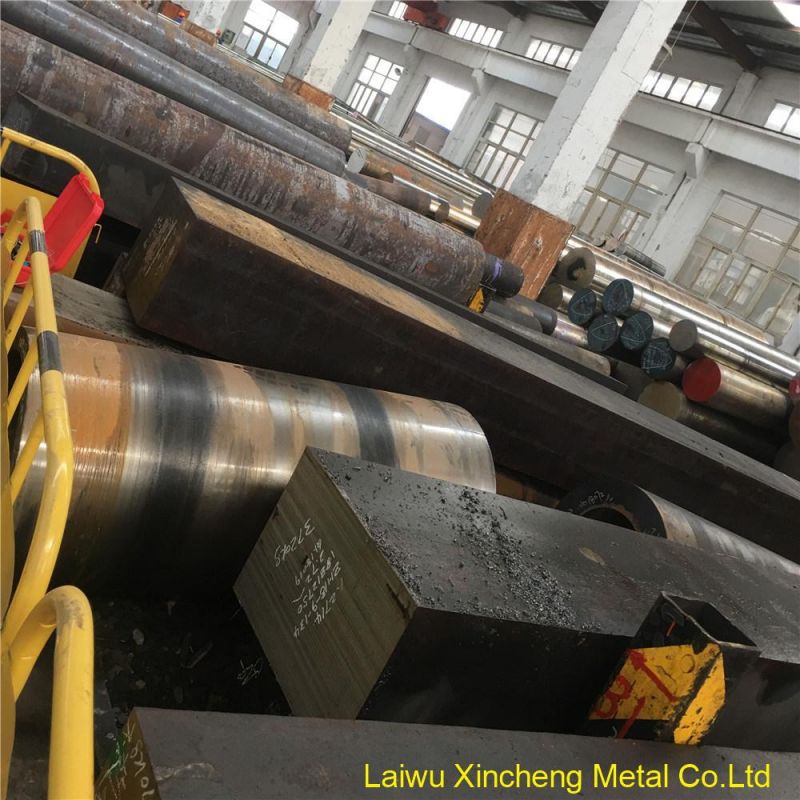

En 10083-2 / C45 1.1191 Forged Round Steel Bars / C45e Hammer Forged Steel Square Bar

Laiwu Xincheng Metal Co., Ltd.- Application:Structural Steel Bar, Tool Steel Bar, Die Steel Bar

- Technique:Forged

- Standard:AISI, ASTM, GB, JIS, DIN, BS

- Type:Alloy Steel Bar

- Alloy:Alloy

- Special Use:Alloy Steel

Base Info

- Transport Package:Standard Sea Worthy

- Grades:1.1191 C45 S45c 1045

- MOQ:One Piece

- Heat Treatment:Annealed, Normalized, Qt

- Delivery Condition:Forged , Forged+Rough Turned

- Specification:200-1000mm

- Origin:China

- Production Capacity:3000tons,Month

Description

Basic Info.

Delivery Condition Forged / Forged+Rough Turned Heat Treatment Annealed, Normalized, Qt MOQ One Piece Grades 1.1191 C45 S45c 1045 Transport Package Standard Sea Worthy Specification 200-1000mm Origin China Production Capacity 3000tons/MonthProduct Description

EN 10083-2 / C45 1.1191 Forged Round Steel Bars / C45E Hammer Forged Steel Square Bar1.C45E/1.1191 forged steel bar sizes we can offer;

Round bar: 200-1000mm

Square bar:150×150-600×600mm

2.Supply condition for C45E/1.1191 Forged steel bars:Black /Rough Machined /Rough turned

3.C45E/1.1191 Forged Steel round bar tolerance:

Black surface

Forged sizes up to 500mm (-0/+5mm)

Forged sizes above 500mm in diameter (-0/+8mm)

Machined surface to all sizes (-0/+3mm)

4.Futhur heat treatment for C45E/1.1191 forged steel :

Normalized

Annealed

Q&T(Quenched&Tempered)

5.C45E/1.1191 Steel Equivalent

AFNOR XC 42 TS AFNOR XC 45 AFNOR XC 48 AFNOR XC42

DIN 1.1191 JIS S 45C JIS S 48 C SS 1672

ASTM A29 ASTM A510 ASTM A519 ASTM A576

FED QQ-S-635 (C1045) FED QQ-S-700 (1045) SAE J403 ASTM A682

SAE J414 ASTM A183 (2-Nuts) ASTM A236 (1045) SAE J412

ASTM A266 (1045) ASTM A827 ASTM A830 QQ S700 (C1045)

SAE J1397 (1045)

6.C45E/1.1191 Forged steel chemical composition

| Standard | Grade | C | Si | Mn | P | S |

| GB/T699 | 45 | 0.42-0.5 | 0.17-0.37 | 0.5-0.8 | 0.035 | 0.035 |

| JIS G4051 | S45C | 0.42-0.48 | 0.15-0.35 | 0.6-0.9 | 0.03 | 0.035 |

| ASTM A29/A29M | 1045 | 0.43-0.5 | 0.15-0.35 | 0.6-0.9 | 0.04 | 0.05 |

| EN 10083-2 | C45E/1.1191 | 0.43-0.5 | 0.4 | 0.5-0.8 | 0.03 | 0.035 |

7.C45E/1.1191 Forged steel Application

Gears Pins Rams

Shafts Rolls Sockets

Axles Spindles Worms

Bolts Ratchets Light gears

Studs Crankshafts Guide rods

Connecting rods Torsion bars Hydraulic clamps

8.Quality control:

1. Melting Process: EAF/BOF+LF+VD resulting in ingots

2. Both ends cut by saw

3. Ratio of forging:minimum 3:1

4. Grain size of final product: according to ASTM E112 more than 5,preferred more than 8

5. Ultrasonic test: As per SEP1921 Class C/c or D/d

9.Heat treatment of C45E/1.1191 Steel

Forging

Heat to 850°C - 1250°C (1562°F - 2282°F)

Hold until the temperature is uniform

Cool in furnace

Annealing

Heat to 800°C - 850°C (1472°F - 1562°F)

Hold until the temperature is uniform

Cool in furnace.

Normalizing

Heat to 870°C - 920°C (1598°F-1688°F)

Hold until the temperature is uniform

Soak for 10 - 15 minutes

Cool in still air

Stress Relieving

Heat to 550°C - 660°C (1022°F - 1220°F)

Hold until the temperature is uniform

Soak for 1 hour per 25mm of section

Cool in still air

Hardening

Heat to 820°C - 850°C (1508°F - 1562°F)

Hold until the temperature is uniform

Soak for 10 - 15 minutes per 25mm of section

Quench in water or brine

Tempering

Re-heat to 400°C - 650°C (752°F - 1202°F ) as required

Hold until the temperature is unifo

10.MOQ: one piece per size/grade

11.Payment term: FOB CIF CFR EXW and so on

12.Delivery time : 7 to 30 days after deposit received.

EN 10083-2 / C45 1.1191 Forged Round Steel Bars / C45E Hammer Forged Steel Square Bar

EN 10083-2 / C45 1.1191 Forged Round Steel Bars / C45E Hammer Forged Steel Square Bar

EN 10083-2 / C45 1.1191 Forged Round Steel Bars / C45E Hammer Forged Steel Square Bar