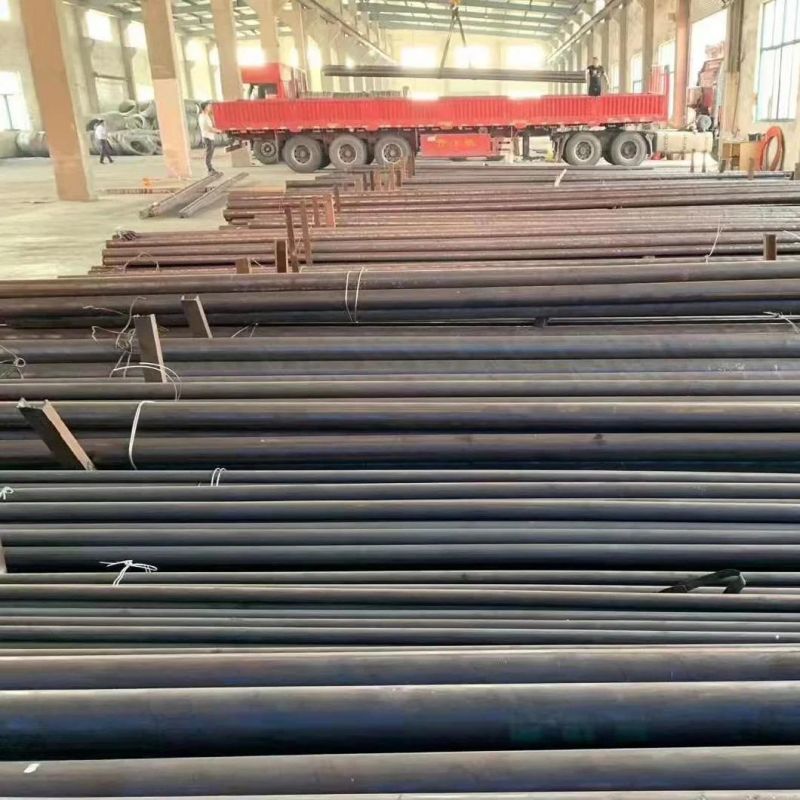

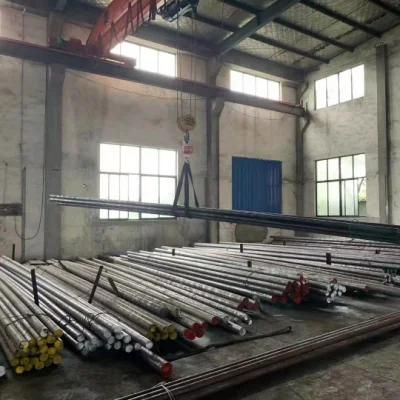

Diameter 8 - 300mm Ss Bar 316L Stainless Steel Bright Bar / Stainless Steel Black Bar

Wuxi City Ge Ming Sheng Steel Trading Co., Ltd- Certification:AISI

- Grade:300 Series

- Standard:ASTM

- Type:Stainless Steel Bars

- Shape:Round

- Technique:Cold Rolled

Base Info

- Production Capacity:50000kgs

- Specification:OD 6-630mm

- Transport Package:Wooden Box

- Surface Treatment:Bright

- Model NO.:316L

Description

Corrosion Resistance of 316L Stainless Steel

Excellent in a range of atmospheric environments and many corrosive media - generally more resistant than 304. Subject to pitting and crevice corrosion in warm chloride environments, and to stress corrosion cracking above about 60 °C. Considered resistant to potable water with up to about 1000 mg/L chlorides at ambient temperatures, reducing to about 500 mg/L at 60 °C.

316 is usually regarded as the standard "marine grade stainless steel", but it is not resistant to warm seawater. In many marine environments, 316 does exhibit surface corrosion, usually visible as brown staining. This is particularly associated with crevices and rough surface finish.

Heat Resistance of 316L Stainless Steel

Good oxidation resistance in intermittent service to 870 °C and in continuous service to 925 °C. Continuous use of 316 in the 425-860 °C range is not recommended if subsequent aqueous corrosion resistance is important. Grade 316L is more resistant to carbide precipitation and can be used in the above temperature range. Grade 316H has higher strength at elevated temperatures and is sometimes used for structural and pressure-containing applications at temperatures above about 500 °C.

Heat Treatment of 316L Stainless Steel

Solution Treatment (Annealing) - Heat to 1010-1120 °C and cool rapidly. These grades cannot be hardened by thermal treatment.

Welding of 316L Stainless Steel

Excellent weldability by all standard fusion and resistance methods, both with and without filler metals. Heavy welded sections in Grade 316 require post-weld annealing for maximum corrosion resistance. This is not required for 316L.

316L stainless steel is not generally weldable using oxyacetylene welding methods.

Machining of 316L Stainless Steel

316L stainless steel tends to work harden if machined too quickly. For this reason, low speeds and constant feed rates are recommended.

316L stainless steel is also easier to machine compared to 316 stainless steel due to its lower carbon content.

Hot and Cold Working of 316L Stainless Steel

316L stainless steel can be hot worked using the most common hot working techniques. Optimal hot working temperatures should be in the range 1150-1260 °C, and certainly should not be less than 930 °C. Post-work annealing should be carried out to induce maximum corrosion resistance.

Most common cold working operations such as shearing, drawing, and stamping can be performed on 316L stainless steel. Post-work annealing should be carried out to remove internal stresses.

Hardening and Work Hardening of 316L Stainless Steel

316L stainless steel does not harden in response to heat treatments. It can be hardened by cold working, which can also result in increased strength.

Applications of 316L Stainless Steel

Typical applications include:

- Food preparation equipment particularly in chloride environments.

- Pharmaceuticals

- Marine applications

- Architectural applications

- Medical implants, including pins, screws and orthopedic implants like total hip and knee replacements

- Fasteners