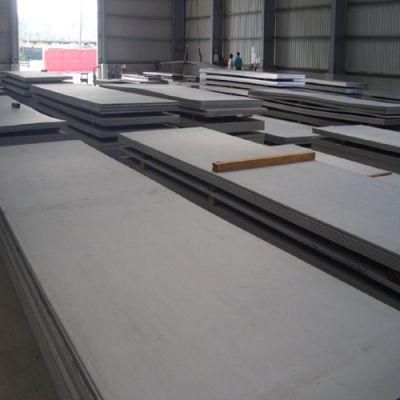

Duplex 2205 Stainless Steel Sheet Price List

WUXI BAOWANG STEEL CO., LTD.- Application:Ship Plate, Boiler Plate, Container Plate, Chemical, Metallurgy, Boiler

- Technique:Cold Rolled

- Surface Treatment:Coated

- Certification:ISO, RoHS, IBR

- Type:Steel Plate

- Standard:ASTM, AISI, GB, JIS, DIN, BS

Base Info

- Transport Package:Standard Export Package or as Required

- Delivery Time:Depend on Quantity

- Stock:Stock

- Special Use:Cutting Tools, Cutters in Common Steel, High-strength Steel Plate, Wear Resistant Steel

- Model NO.:2205

- Origin:Mainland China

- HS Code:7219900000

- Production Capacity:1000 Tons Per Month

Description

Basic Info.

Model NO. 2205 Special Use Cutting Tools, Cutters in Common Steel, High-strength Steel Plate, Wear Resistant Steel Stock Stock Delivery Time Depend on Quantity Transport Package Standard Export Package or as Required Origin Mainland China HS Code 7219900000 Production Capacity 1000 Tons Per MonthProduct Description

Quick Details

- Standard: ASTM, AISI, DIN, EN, GB, JIS

- Length: 320mm~10000mm

- Thickness: 0.3mm--12mm

- Width: 1000mm--1524mm

- Place of Origin: Jiangsu, China (Mainland)

- Brand Name: TISCO, JISCO, BISCO, KSK

- Model Number: duplex 2205 stainless steel sheet price list

- Type: Plate

- Application: chemical, metallurgy, boiler

- Certification: ISO SGS BV

- Surface: 2B/NO.4/HL/NO.1/BA

- Special Use: High-strength Steel Plate

- Technique: hot rolled,cold rolled

- Sample: Free

- Best Service: Aftersale services

- Quality Assurance: The third party testing

- Note: We can also do other materials

- Delivery: Short

- Small order: Take sth seriously

- Stocks: 500tons

Packaging & Delivery

| Packaging Details: | Export standard package :bundled wooden box or be required For duplex 2205 stainless steel sheet price list |

|---|---|

| Delivery Detail: | 15--30 DAYS |

2205 duplex 2205 stainless steel sheet price list

2205 is a duplex (austenitic-ferritic) stainless steel containing about 40 - 50% ferrite in the annealed condition. 2205 has been a practical solution to chloride stress corrosion cracking problems experienced with 304/304L or 316/316L stainless.

The high chromium, molybdenum and nitrogen contents provide corrosion resistance superior to 316/316L and 317L stainless in most environments.

2205 is not suggested for operating temperatures up to 600°F.

The design strength of 2205 is significantly higher than 316/316L, often permitting lighter wall construction.

2205 has good notch impact toughness down to temperatures below - 40°F. 2205 is welded with E2209 or ER2209 fillers.

Chemistry

| Ni | Cr | Mo | Mn | Si | C | N | S | P | Fe |

MIN | 4.5 | 22.0 | 3.0 | - | - | - | 0.14 | - | - | - |

MAX | 6.5 | 23.0 | 3.5 | 2.0 | 1.0 | 0.03 | 0.2 | 0.02 | 0.03 | Balance |

Specifications

ASME SA 182, ASME SA 240, ASME SA 479, ASME SA 789, ASME SA 789 Section IV Code Case 2603

ASTM A 240, ASTM A 276, ASTM A 276 Condition A, ASTM A 276 Condition S, ASTM A 479, ASTM A 790

NACE MR0175/ISO 15156

NORSOK MDS D45 Grade F51

UNS S31803, UNS S32205

W. NR./EN 1.4462

Inventory

2205 Coil, 2205 Pipe, 2205 Plate, 2205 Sheet, 2205 Welding Products

Common Trade Names

2205 Stainless, Duplex 2205

Features

- High resistance to chloride stress corrosion cracking

- Chloride pitting and crevice corrosion resistance superior to 317L stainless

- Good general corrosion resistance

- High strength

- Good sulfide stress corrosion resistance

- Useful up to 600°F

- Chemical process vessels, piping, and heat exchangers

- FGD scrubber systems

- Pulp mill digesters, bleach washers, chip presteaming vessels

- Food process equipment

- Oil field piping, heat exchangers

Applications

Physical Properties

Density: 0.278 lb/inch3

Melting Point: 2525- 2630°F

Poisson's Ratio: 0.3

Electrical Resistivity: 481 Ohm - circ mil/ft

Temperature, °F | 70 | 212 | 392 | 572 |

Coefficient* of Thermal Expansion, in/in°F x 10-6 | - | 8 | 8 | 8 |

Thermal Conductivity | 8 | 9 | 10 | 11 |

Modulus of Elasticity, Dynamic psi x 106 | 28 | 26 | 25 | 24 |

* 70°F to indicated temperature.

Mechanical Properties

Minimum Specified Properties, ASTM A 240

Ultimate Tensile Strength, ksi | 95 |

0.2% Yield Strength, ksi | 65 |

Elongation, % | 25 |

Hardness MAX, Brinell | 290 |

Minimum Elevated Tensile Properties, Plate

Temperature, °F | 212 | 302 | 392 | 482 |

Ultimate Tensile Strength, ksi | 86 | 83 | 80 | 78 |

0.2% Yield Strength, ksi | 52 | 49 | 46 | 44 |

Corrosion Resistance

| PREn | Critical Pitting Temperature, CPT |

2205 | 34 | 130°F |

316L | 24 | 62°F |