Ss400 S20c 1020 1045 Cold Drawn Peeled Ground Steel Round Bars

Laiwu Xincheng Metal Co., Ltd.- Application:Structural Steel Bar

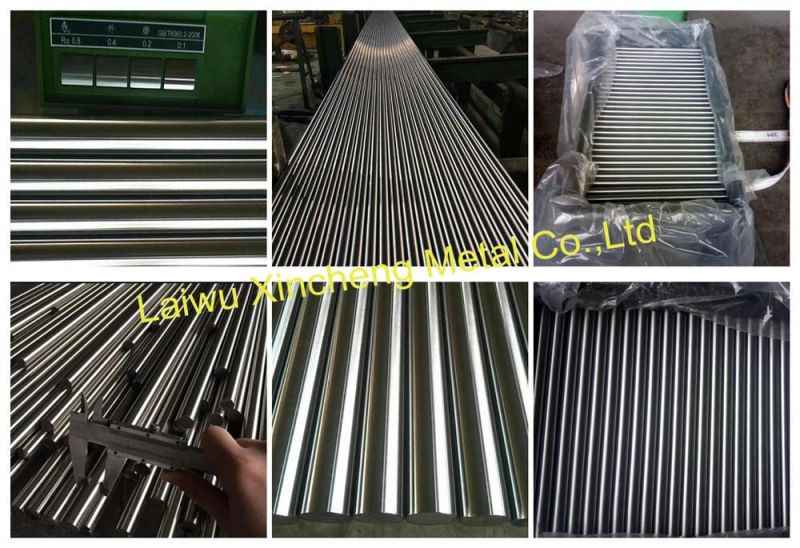

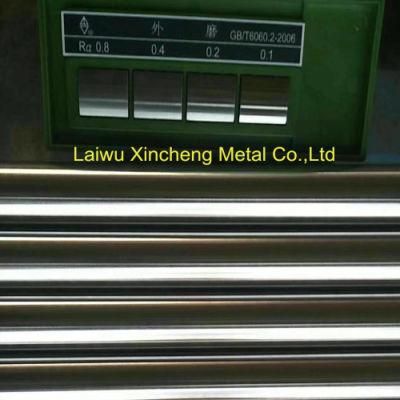

- Technique:Polished

- Standard:AISI, ASTM, GB, JIS, DIN, BS

- Type:Carbon Steel Bar

- Surface Treatment:Polished

- Alloy:Non-alloy

Base Info

- Certificate:Ce SGS Mtc ISO9001

- Processing:Cold Drawn-Turned-Ground-Polished

- Surface Condition:Shinny Bright

- MOQ:2tons

- Straitness:Max 0.2mm,M

- Surface:Surface Anti Rust Oil--Robber "O" Ring--Woven Clot

- Surface Finish:20 Ra Max or as Required

- Equivalengt Grade:SAE 1045, S45c, C45, Ck45

- Products:SAE 1045 Bright Steel Round Bar

- Special Use:Mold Steel, Free Cutting Steel, Cold Heading Steel

- Model NO.:SS400 S20C 1020 1045

- Commodity:Bright Steel Round Bars

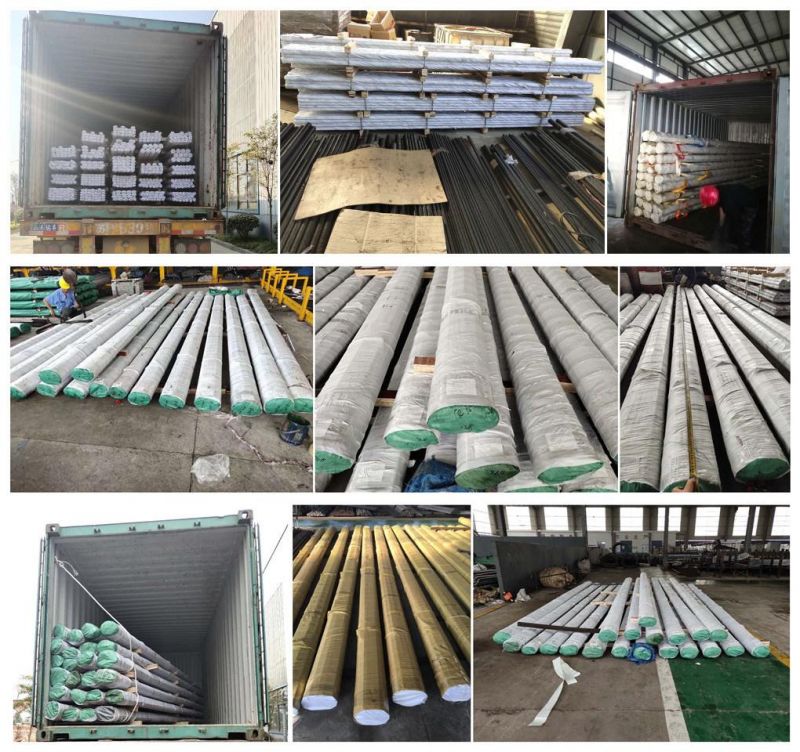

- Transport Package:Anti-Rust Packing

- Specification:M20-M120

- Production Capacity:1000tons,Month

Description

Basic Info.

Model NO. SS400 S20C 1020 1045 Special Use Mold Steel, Free Cutting Steel, Cold Heading Steel Products SAE 1045 Bright Steel Round Bar Equivalengt Grade SAE 1045, S45c, C45, Ck45 Surface Finish 20 Ra Max or as Required Straitness Max 0.2mm/M Surface Surface Anti Rust Oil--Robber "O" Ring--Woven Clot MOQ 2tons Surface Condition Shinny Bright Processing Cold Drawn-Turned-Ground-Polished Certificate Ce SGS Mtc ISO9001 Commodity Bright Steel Round Bars Transport Package Anti-Rust Packing Specification M20-M120 Production Capacity 1000tons/MonthProduct Description

Bright steel bars is a processing which is to remove the oxide scale mill scalesurface cracksetc. From hot rolled and forged blacks. The most peeled common materials are carbon steel and spring steels. The bar is produced from excellent quality steel using precision manufacturing Peeled bar is wlays supplied in the polished and straitened conditions. Peeled steel bars are widely used because of the smoother surface closer tolerance and better straightnees for mechanical parts and industries. Our peeled steel bars can help customer to retionalize production and reduce production costs.SS400 S20C 1020 1045 Cold Drawn Peeled Ground Steel Round Bars1.Application :

CONSTRUCTION & HEAVY EQUIPMENT-Piston Rods, Bolts, Crankshafts, Driveshafts, Feed Screws, Axles

AGRICULTURE-Piston Rods, Driveshafts, Crankshafts, Bolts, Feed Screws, Axles

INFRASTRUCTURE-Rolls, Journals, Bolts

FLUID HANDLING -Pump Shafts

MACHINERY-Arbors, Journals, Spindles, Pins, Feed Screws

OIL & GAS-Gears, Piston Rods, Multiple shaft applications

ENERGY-Gears, Wind Turbine Shafts, Stub Shafts

GENERAL FABRICATION AND MACHINING-Gears, Trunnion Wheels, Mandrels, Sockets, Any application where a shaft is required

AUTOMOTIVE & TRANSPORTATION-Crankshafts, Driveshafts, Piston Rods, Wrist Pins, Stub Shafts, Axles, Torsion Bars

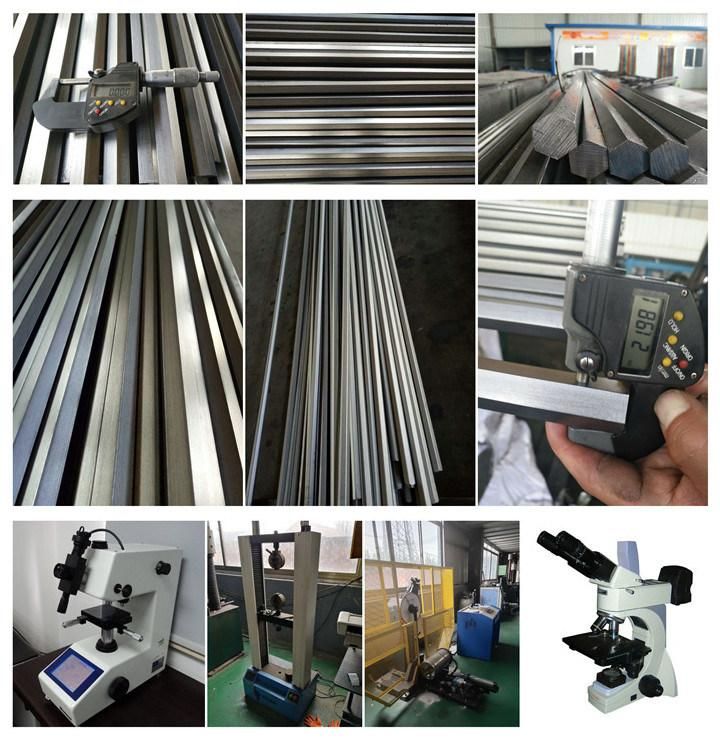

2.Sizes, Proceesing and Tolerance

| Diameter | Length | Supply Condition | Tolerance | Straightness |

| 5mm to 16mm | 1-10mtr | Shot blasting, Cold Drawn | h8 h9, h10, h11/ as required | <=0.8mm/m |

| 16 mm to 70 mm | 1-10mtr | Peeled( Ground & Polished ) | h8 h9, h10, h11/ as required | <=0.2mm/m |

| 70 mm to 100 mm | 1-10mtr | Peeled( Ground & Polished ) | h8 h9, h10, h11/ as required | <=0.2mm/m |

| 105 mm to 200 mm | 1-10mtr | Peeled( Ground & Polished ) | h8 h9, h10, h11/ as required | <=0.2mm/m |

Typically, 20 Ra max or as required

4.Straitness:

Max 0.2mm/m

5.SAE 1045 Steel Chemical composition

| Element | Content |

| Carbon, C | 0.420 - 0.50 % |

| Iron, Fe | 98.51 - 98.98 % |

| Manganese, Mn | 0.60 - 0.90 % |

| Phosphorous, P | ≤ 0.040 % |

| Sulfur, S | ≤ 0.050 % |

6.Packing:

Surface anti rust Oil--Robber "O" Ring--Woven Cloth--Wooden Box

7.MOQ:2tons

8.Delivery time

7-15days of stock,30 days after order confirmed for new productions

We company have good QC inspection tear and full set of inspect equipment including: UT test machine, Tensile testing machine,Hardness testing machine,Dimensional measuring instrument,f,spectrometer,Metallographic microscope and so on, so that we can always supply good mateterials for various projects and industries , if you have any need for our products,please contact us freely.