Hot Selling Galvanized Sheet Metal Galvanized Steel Sheet Ms Plates 5mm Cold Steel Plate

Shandong Zhongyi Steel Co., Ltd.- Surface:Galvanized

- Packing:Seaworthy Package

- Material:Sghc, SGCC, Dx51d, Q195, All According to The Cust

- Capacity:About 15000 Tons Per Month for The Steel Sheet an

- Thickness:0.12mm-4.0mm, All Available

- Length:6m and 5.8m or as Customer′s Request

Base Info

- Skin Pass:Yes

- Processing Service:Welding, Cutting

- Tolerance:±1%

- Hardness:Hard

- Quality:Approved by SGS

- Technology:Hot Dipped,Cold Rolled

- Spangle:Big Spangle, Normal Spangle, Small Spangle, Non-Sp

- Coating Weight:30-275G,M2,Double Side

- Transport Package:Lined with a Waterproof Inner Packaging.

- Origin:China

- HS Code:7210300000

- Production Capacity:30000 Tons,Month

Description

Why You Should Choose Zhongyi Steel Group

Why You Should Choose Zhongyi Steel GroupFor All Your Galvanized Steel Needs

When you work with our manufacturing factory, you're working with one of the most dedicated and professional teams in the industry. We go above and beyond to provide you with the high-quality galvanized steel materials, coils, sheets, and more that you need, without wasting your time, efforts, or investments. Each piece of pre-painted galvanized iron that leaves our premises is of the highest possible quality to make sure that you're satisfied with your purchase, every single time.

Instead of providing you with low-quality, cheap imitations of this exceptional material, we've taken the time to check, perfect, and carefully manufacture the highest caliber of pre-painted galvanized iron.

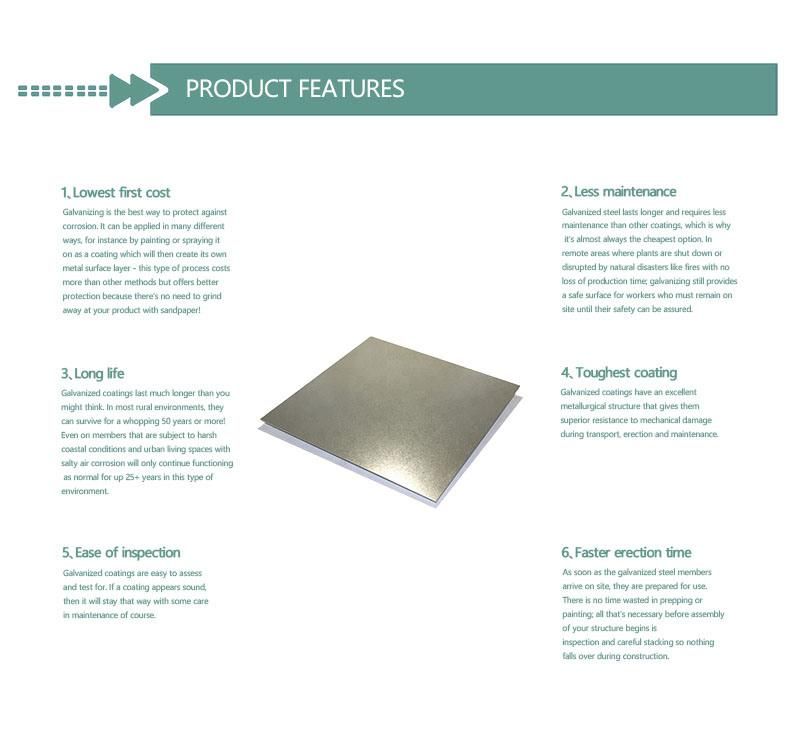

Automatic protection for damaged areas. Galvanized coatings corrode preferentially to steel, providing cathodic or sacrificial protection to small areas of steel exposed through damage. Unlike organic coatings, small damaged areas need no touch up.

Complete protection. Every part of a galvanized article is protected, even recesses, sharp corners and inaccessible areas. No coating applied to a structure or fabrication after completion can provide the same protection.

Ease of inspection. Galvanized coatings are assessed readily by eye, and simple non-destructive thickness testing methods can be used. The galvanizing process is such that if coatings appear sound and continuous, they are sound and continuous.

Faster erection time. As galvanized steel members are received they are ready for use. No time is lost on-site in surface preparation, painting and inspection. When assembly of the structure is complete, it is immediately ready for use, or for the next construction stage.

A full protective coating can be applied in minutes; The galvanizing process is not dependent on weather conditions

Quality You Can Trust

What Makes Our GI Products Superior?

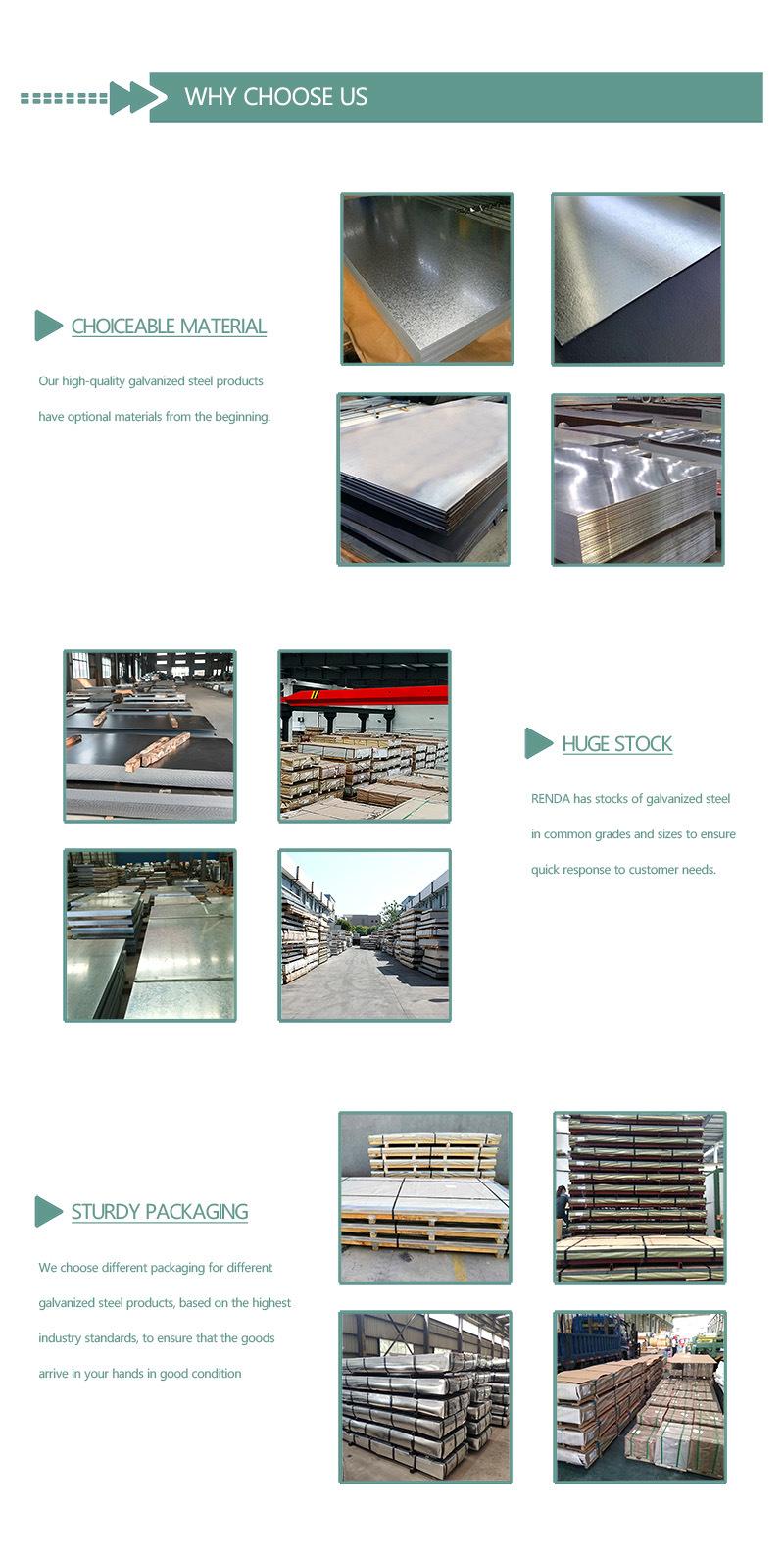

From the quality of our zinc coatings to the care and attention that goes into how we package each and every one of our orders, everything we do is done with incredible precision. Our manufacturing processes are complex. We've made sure that each step is as cost-efficient as possible without ever compromising on quality.