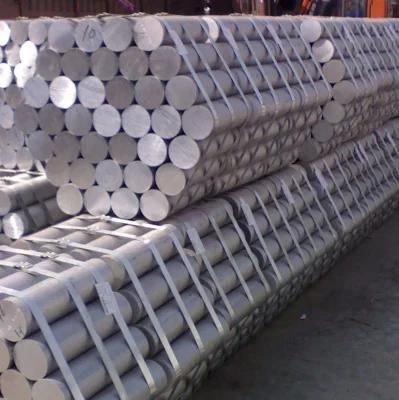

Low Alloy Tool Steel Bar DIN C110W

Wuxi Taixie Metal Material Co., Ltd.- Technique:Hot Rolled

- Composition:Ferrous Steel Scrap

- Standard:AISI, ASTM, DIN, JIS, GB

- Type:Special Steel Bar

- Shape:Bar

- Surface Treatment:Polished

Base Info

- Transport Package:Woven Bag, Wooden Box

- OEM:Yes

- Delivery Time:5~10 Working Days

- Yield Strength:225

- Certificate:ISO SGS

- Poisson′s Ratio:0.25~0.33

- Strength:375-500

- Elongation:25

- Application:Tool Steel Bar

- Special Use:High-strength Steel Plate, Wear Resistant Steel, Silicon Steel, Cold Heading Steel, Free Cutting Steel, Mold Steel

- Model NO.:ASB5

- Specification:ISO SGS

- Trademark:Taixie

- Origin:Wuxi, Jiangsu

- HS Code:7507120000

- Production Capacity:10000tons,Y

Description

Basic Info.

Model NO. ASB5 Special Use High-strength Steel Plate, Wear Resistant Steel, Silicon Steel, Cold Heading Steel, Free Cutting Steel, Mold Steel Application Tool Steel Bar Elongation 25 Strength 375-500 Poisson′s Ratio 0.25~0.33 Certificate ISO SGS OEM Yes Delivery Time 5~10 Working Days Yield Strength 225 Transport Package Woven Bag, Wooden Box Specification ISO SGS Trademark Taixie Origin Wuxi, Jiangsu HS Code 7507120000 Production Capacity 10000tons/YProduct Description

Key Specifications/Special Features:Description

Low alloyed cold working tool steel.

Applications

Cutting tools for steels and metals, broaching tools, thread cutting tools, files, chisels, drawing dies, cutting tools for the hardest stone.

Chemical composition (in weight %)

C 1.38

Si 0.20

Mn 0.23

Physical properties (average values) at ambient temperature

Modulus of elasticity [103xN/mm2]: 210

Density [g/cm3]: 7.85

Soft annealing

Heat to 680-720ºC, cool slowly. This will produce a maximum Brinell hardness of 210.

Stress relieving

Stress relieving to remove machining stresses should be carried out by heating to approx. 600-650ºC, holding for 1-2 hours at heat, followed by air cooling. This operation is performed to reduce distortion during heat treatment.

Hardening

Harden from a temperature of 760-780ºC followed by oil or water quenching with addition of NaCl. Hardness after quenching is approx. 65 HRC.

Forging

Hot forming temperature: 1000-800ºC.

Specifications:

Grade: DIN C135W

Standard: DIN, GB

Diameter: 50-500mm

Certification: ISO

Technical treatment: cold-rolled and hot rolled

Packing and delivery

Packing: standard export seaworthy package or as customers' requirements.

Delivery: 7-20 days after received deposit of T/T.

| C | Mn | Si | P | S | Cr | Ni | Mo |

| 0.03 | 0.5 | 0.5 | 0.02 | 0.005 | 11.5~13.5 | 4.5~6.5 | 1.5~3.5 |

Mechanical behavior

State: hardening and tempering state. The supply status is typically 95 or 110 ksi, 0.2% yield strength

Extreme tensile strength: 115 ksi or more (792N / mm2)

0.2% Yield point: 110 ksi or more (758 N / mm2)

Elongation: 15%

V-notch impact strength (-10 ° C): 78 Joules (60ft-lbf)

Hardness: 33%