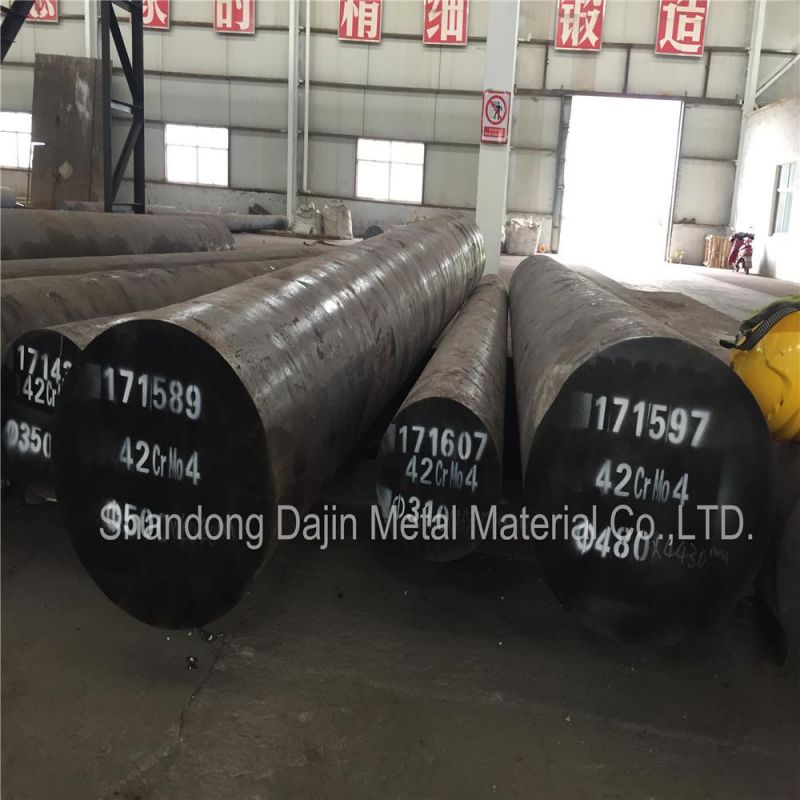

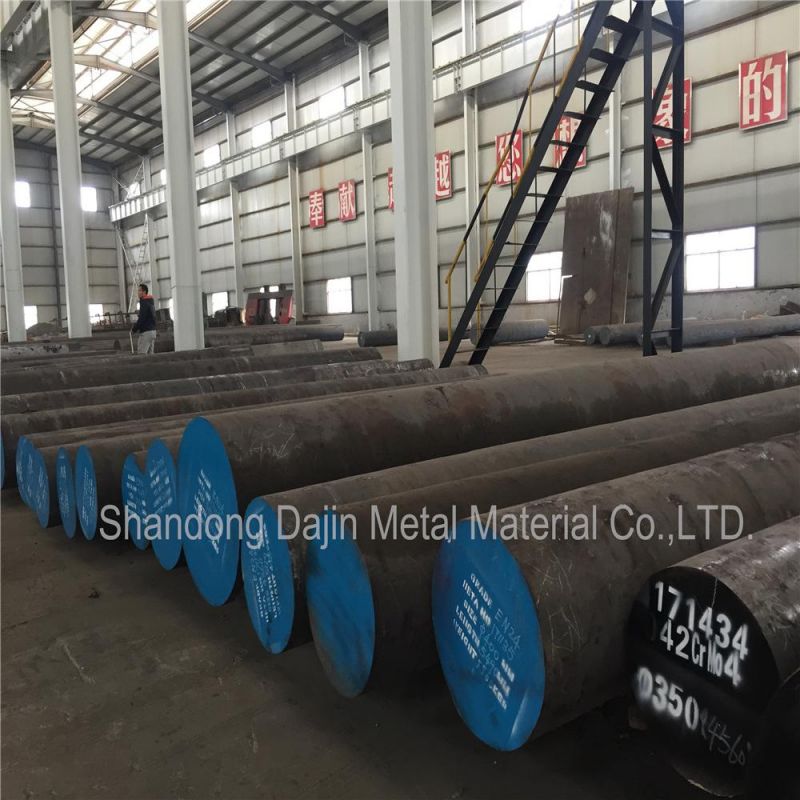

Forged Steel Round Bar Alloy Steel Forged Shaft for Suger Mill Shaft

Shandong Dajin Metal Material Co., Ltd.- Technique:Forged

- Composition:Alloy Steel Bar

- Standard:AISI, ASTM, DIN, JIS, GB

- Type:Round

- Shape:Bar

- Surface Treatment:Black Surface or Rough Machine

Base Info

- Transport Package:Seaworth Packaging

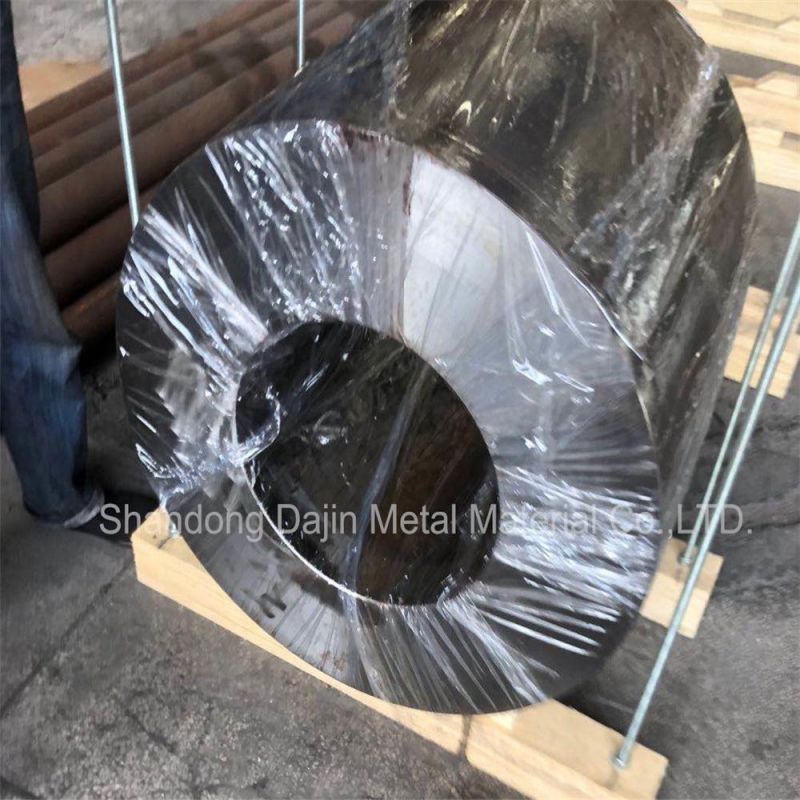

- Forging Rings:Yes

- Cutting Service:Yes

- Main Grade:4140 4340 4150 4145 8620

- Main Material:Carbon or Allloy

- Forged Shaft:Rough Machine

- Supply Condition:Hot Forged or Qt

- Application:Structural Steel Bar

- Special Use:Free Cutting Steel, Mold Steel

- Model NO.:steel bar

- Specification:200mm-1000mm

- Trademark:Shandong

- Origin:China

- Production Capacity:2000tons

Description

Basic Info.

Model NO. steel bar Special Use Free Cutting Steel, Mold Steel Application Structural Steel Bar Supply Condition Hot Forged or Qt Forged Shaft Rough Machine Main Material Carbon or Allloy Main Grade 4140 4340 4150 4145 8620 Cutting Service Yes Forging Rings Yes Transport Package Seaworth Packaging Specification 200mm-1000mm Trademark Shandong Origin China Production Capacity 2000tonsProduct Description

Forged steel round barsEN19 EN24 froged round steel bars

Hot forging shafts

Alloy Steel Round Bar 4140 1.7225

.Chemical Composition (%):

| Grade | C | Si | Mn | P | S | Cr | Mo |

| 42CrMo4 | 0.38-0.45 | 0.17-0.37 | 0.40-0.70 | ≤0.035 | ≤0.035 | 0.90-1.20 | 0.15-0.25 |

| 1.7225 | 0.38-0.45 | ≤0.40 | 0.60-0.90 | ≤0.025 | ≤0.035 | 0.90-1.20 | 0.15-0.30 |

| 4140 | 0.38-0.43 | 0.15-0.35 | 0.75-1.00 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

Round: Dia. 16 - 1000mm

16mm-350mm with hot rolled supply condition;

200-1000mm with forged supply condition

3.Delivery condition: Hot rolled or forged, Peeled or black surface, annealed or QT.

4.Applications:

Statically and dynamically stressed components for vehicles, engines and machines. For parts of larger cross-sections, crankshafts, gears.

5.Heat Treatment:

Soft annealing: heat to 680-720°C, cool slowly.

Hardness after annealing: Max. 241 HB

Hardening: 820 - 850 °C

Normalizing temperature: 840-880°C

Tempering: 540-680°C

6. Inspection: 100% Ultrasonic according to the test standards:SEP1921-84,GR.3 CLASS C/C

7. Packing situation: standard seaworthy packing or as customer required

8. Delivery time: 30 days after order confirmed

9. Process: EAF+LF+VD ( necessary) +UT+ Peeled(optional) +Turned (optional) + Heat Treatment (optional)

Keywords:forged steel bar/en19 forged steel bars/en24 forged steel bar/forging shafts/forging ring

forged steel bar/en19 forged steel bars/en24 forged steel bar/forging shafts/forging ring

forged steel bar/en19 forged steel bars/en24 forged steel bar/forging shafts/forging ring

FORGED STEEL BAR IN PAKISTAN,FORGED SHAFT STEEL,PAKISTAN FORGED ROLLER SHAFT,ROLLER SHAFT 4140,SAE8620 alloy steel bar,forged round bar