Metal Iron Zinc Roofing Tiles Corrugated Profile Plate Color Coated Galvanized Steel Sheet in Coil/PPGI

Shandong Zhongyi Steel Co., Ltd.- Technique:Cold Rolled

- Surface Treatment:Galvanized

- Certification:ISO

- Standard:ASTM, JIS, GB, DIN, BS

- Warranty:3 Years Warrenty

- Application:Boiler Plate

Base Info

- Coil Weight:3-8 Tons Per Coil

- Back Side:Primer Epoxy

- Top Side:Primer Paint+Polyester Paint Coating

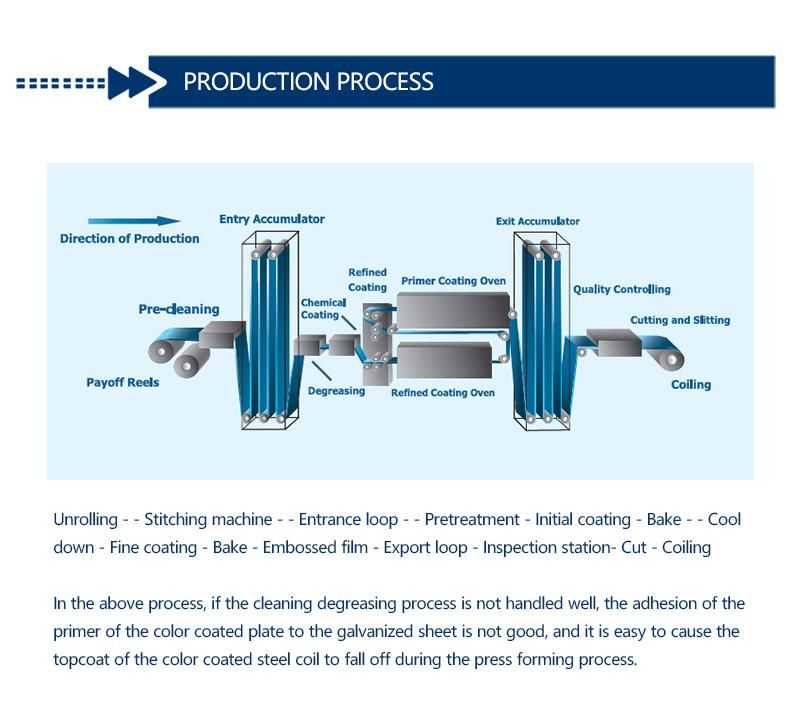

- Coating Process Front:Double Coated&Double Drying, Single Coated&Double

- Surface:Embossed, Mill Finish, Coated

- Color:All Ral Colors, or According to Customers Require

- Zinc Coating:40-275 G,M2

- Thickness:0.13-2.0mm

- Width:600-1500mm

- Type:Commercial Quality,Dq

- Grade:SGCC Sgcd or Customer′s Requirement

- Technical Standard:ASTM DIN GB JIS3312

- Product Name:PPGI, Prepainted Galvanized Steel Coil

- Stock:Stock

- Edge:Slit edge

- Package:Standard Export Package or Customized

- Transport Package:Lined with a Waterproof Inner Packaging.

- Origin:China

- HS Code:3926909090

- Production Capacity:30000 Tons,Month

Description

Ease of inspection. Galvanized coatings are assessed readily by eye, and simple non-destructive thickness testing methods can be used. The galvanizing process is such that if coatings appear sound and continuous, they are sound and continuous.

Ease of inspection. Galvanized coatings are assessed readily by eye, and simple non-destructive thickness testing methods can be used. The galvanizing process is such that if coatings appear sound and continuous, they are sound and continuous.Faster erection time. As galvanized steel members are received they are ready for use. No time is lost on-site in surface preparation, painting and inspection. When assembly of the structure is complete, it is immediately ready for use, or for the next construction stage.

A full protective coating can be applied in minutes; The galvanizing process is not dependent on weather conditions

Quality You Can Trust

What Makes Our GI Products Superior?

From the quality of our zinc coatings to the care and attention that goes into how we package each and every one of our orders, everything we do is done with incredible precision. Our manufacturing processes are complex. We've made sure that each step is as cost-efficient as possible without ever compromising on quality.