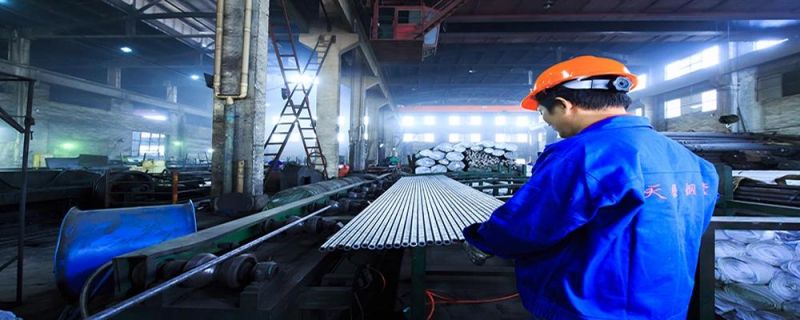

Top Quality Seamless Tubes for Heat Exchangers

Changzhou Tenjan Steel Tube Co., Ltd.- Usage:Pipeline Transport, Boiler Pipe, Hydraulic,Automobile Pipe, Oil,Gas Drilling, Machinery Industry, Chemical Industry, Construction & Decoration

- Surface Treatment:Polished

- Material:Carbon Steel

- Warranty:3 Years

- Type:Seamless

- Technique:Cold Drawn

Base Info

- Specification:Varnish, Plastic Caps, in Bundled, or Customized

- Transport Package:Sea Transportation

- Tolerance:±0.15mm

- Tech:Cold Drawn , Cold Rolled

- Length:Less Than 11.8m

- Wall Thickness:1-20mm (0.04 Inch - 0.78 Inch)

- Outer Diameter:10-120mm (0.4 Inch - 4.7 Inch)

- Carbon Steel:GB,T 8162 & 8163 & 3639

- Section Shape:Round

- Trademark:Tenjan

- Origin:China

- HS Code:7304319000

- Production Capacity:50000 Ton,Year

Description

Material / Grade

Carbon Steel:

GB/T 8162 & 8163 & 3639: 10#, 20#, 35#, 45#, 55#, Q235B, Q235C, CF53, A105

ASTM A519: 1010, 1020, 1026, 1035, 1045, 1050

DIN17121/EN 10297-1, DIN1629/DIN2391/EN 10305-1: C10/CK10, C22/CK22, C35/CK35, C45/CK45, CF53

JIS3441/JIS3444/JIS3445: STKM11A, STKM12A/STKM12B/STKM12C, STKM13A/STKM13B/STKM13C

JIS G4051: S10C, S20C, S25C, S35C, S45C, S55C

Alloy Steel:

GB/T 8162 & 8163 & 3639: 16Mn(Q345B), 20Cr, 40Cr, 15CrMo, 20CrMo, 28CrMo, 30CrMo, 35CrMo, 42CrMo, 20CrMnTi, 40MnMoV, 20Mn2, ZF6, 16MnCr5, 20MnCr5, 38Mn2V, 09CrCuSb(ND)

ASTM A519: 5120, 5140, 4130, 4135, 4140

DIN17121/EN 10297-1, DIN1629/DIN2391/EN 10305-1: ST52, EN10084-1998 20Cr4, 41Cr4, 15CrMo4, 25CrMo4, 35CrMo4, 42CrMo4, 16MnCr5

JIS3441/JIS3444/JIS3445: SCM432/SCRRM3, SCM4

JIS G4053: JIS SCr420, JIS SCr440, SCM415, SCM420

Tolerance

Tolerance ±0.15mm,Superior products ±0.05mm, Can be customized according to customer's requirements

Technique

Cold Drawn / Cold Rolled

Shape

Round

Further Processing for Steel Tubes

Final Annealing, Cutting, Chamfer, Threading, Inner diameter or Outer Diameter Lathe, Surface Shot Blasting, Laser Marking

2.Production process of seamless steel pipe

Row Material storage/inspection and cutting by saw machine

Hot Perforaction

Squeeze head and raw tube inspection

Cycling pickling

Cycling cold drawing/roling

Cycling annealing

Straightening

Eddy current inspection

Products inspection and test

Tenjan is specialized in custom production of high quality seamless steel tubes under international standards ASTM A519, ASTM A106, ASTM A500, ASME SA500, DIN2391, DIN1629, EN10305-1, DIN17121, EN10297-1, JIS3441, JIS3444 and JIS3445. We provide small batch customization service, especially for small and medium-size enterprises. Raw material, internal and external dimensional tolerances and consistency, internal and external surface roughness, straightness, mechanical properties, eccentricity, special shape, alloy steel, small-diameter thick-walled seamless steel tubes all can be customized. The production range for outer diameter is from 10 to 120mm and for wall thickness is from 1 to 20mm

Tenjan is specialized in custom production of high quality seamless steel tubes under international standards ASTM A519, ASTM A106, ASTM A500, ASME SA500, DIN2391, DIN1629, EN10305-1, DIN17121, EN10297-1, JIS3441, JIS3444 and JIS3445. We provide small batch customization service, especially for small and medium-size enterprises. Raw material, internal and external dimensional tolerances and consistency, internal and external surface roughness, straightness, mechanical properties, eccentricity, special shape, alloy steel, small-diameter thick-walled seamless steel tubes all can be customized. The production range for outer diameter is from 10 to 120mm and for wall thickness is from 1 to 20mm

Why Choose Tenjan?

(1) Large Scale Production,Strong R&D Capability

The annual production capacity can reach 60,000 tons under years of development. Every-year R&D investment and a team of technicians enable Tenjan with strong R&D capability. Tenjan has full system of production with advanced equipment, such as perforation, pickling, cold rolling, cold drawing, straightening, flaw detection, tensile test and machining.

(2) Quality Control

Every batch of products can be traced and guaranteed by the raw material certificate and steel tube quality certificate. Complete quality control system, following ISO9001, to ensure a full inspection process such as pull force test, chemical composition test and eddy current detection.

(3) Certification

The chairman of Tenjan, Mr. Wensheng Gu, is one of the major constitutors of national standard Couplers for Rebar Mechanical Splicing JG/T 163-2013. And Tenjan has won the Quality System Certificates of ISO9001 and IATF16949.

(4) Major Customer Case

We have long-term relationship with customers such as BMW, MCC, CNNP, CRRC, Midea, Sinohydro, China Pingmei, China Academy of Building Research and so on.

(5) Export Countries

Our products were exported to Europe, America, Japan, South Korea, The Middle East, Southeast Asia and in total six continents over 20 countries, and which has been consistently trusted by customers.

(6) Customer Service

Tenjan provides considerate service to every customer with fast feedback, quality track and technical support.