AISI 4140 Alloy Steel/42CrMo4/42crmos4/1.7225/Scm440/42CrMo/Flat Bar/Steel Block/Round Bar

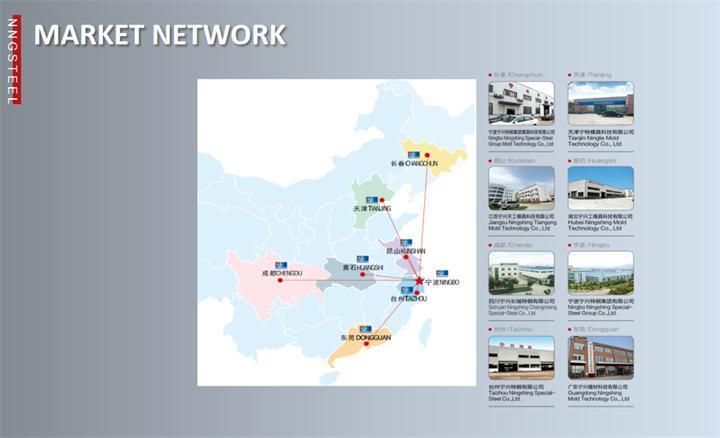

Ningbo Ningshing Precision Machinery Group Co., Ltd.- Special Use:High-strength Steel Plate, Wear Resistant Steel, Silicon Steel, Cold Heading Steel, Free Cutting Steel, Mold Steel

- Surface Treatment:Black, Machined

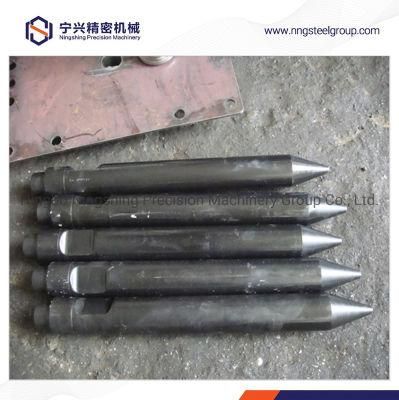

- Shape:Bar

- Technique:Forged

- Standard:AISI, ASTM, DIN, JIS, GB, BS

- Composition:Check Detailed Description

Base Info

- Specification:check detailed description

- Transport Package:Nude Packing

- Application:Die Steel Bar

- Model NO.:42CrMo4

- Trademark:Ningbo Ningshing

- Origin:China

Description

Applications

AISI 4140 Alloy Steel is used for as wide variety of applications where greater toughness and wear resistance is needed over lower carbon grades. Typical applications for 4140 tool steel uses include Components, Adapters, Arbors,strippers, holder blocks, mold bases, ejectors, back up and support tooling, fixtures, jigs, molds, cams, drill collars, Axle Shafts, Bolts, Crankshafts,stubs, couplings, reamer bodies, axles, shafting, piston rods, rams, hydraulic machinery shafts, gears, sprockets, gear racks, chain links, spindles, tool bodies, tool holders, tie rods, Connection Rods, Chuck Bodies, Collets, Conveyor Pins & Rolls, Ejector Pins, Forks, Gears, Guide Rods, Hydraulic Shafts & Parts, Lathe Spindles, Logging Parts, Milling Spindles, Motor Shafts, Nuts, Pinch Bars, Pinions, Pump Shafts,boring bars,tracks, slides, wear strips or parts, forming dies, brake dies, trim dies, bolsters, machinery parts and components, etc.

Mechanical Properties

| Properties | Metric | Imperial |

| Tensile strength | 655 MPa | 95000 psi |

| Yield strength | 415 MPa | 60200 psi |

| Bulk modulus(typical for steel) | 140 GPa | 20300 ksi |

| Shear modulus (typical for steel) | 80 GPa | 11600 ksi |

| Elastic modulus | 190-210 GPa | 27557-30458 ksi |

| Poisson's ratio | 0.27-0.30 | 0.27-0.30 |

| Elongation at break (in 50 mm) | 25.70% | 25.70% |

| Hardness, Brinell | 197 | 197 |

| Hardness, Knoop (converted from Brinell hardness) | 219 | 219 |

| Hardness, Rockwell B (converted from Brinell hardness) | 92 | 92 |

| Hardness, Rockwell C (converted from Brinell hardness. Value below normal HRC range, for comparison purposes only) | 13 | 13 |

| Hardness, Vickers (converted from Brinell hardness) | 207 | 207 |

| Machinability (based on AISI 1212 as 100 machinability) | 65 | 65 |

Fabrication & Heat Treatment

Machinability

AISI 4140 alloy steel has good machinability in the annealed condition.

Forming

AISI 4140 alloy steel has high ductility. It can be formed using conventional techniques in the annealed condition. It requires more pressure or force for forming because it is tougher than plain carbon steels.

Welding

AISI 4140 alloy steel can be welded using all conventional techniques. However, the mechanical properties of this steel will be affected if it is welded in the heat treated condition, and post weld heat treatment should be performed.

Heat Treament

AISI 4140 alloy steel is heated at 845°C (1550°F) followed by quenching in oil. Before hardening, it can be normalized by heating at 913°C (1675°F) for a long period of time followed by air cooling.

Forging

AISI 4140 alloy steel is forged at 926 to 1205°C (1700 to 2200°F)

Hot Working

AISI 4140 alloy steel can be hot worked at 816 to 1038°C (1500 to 1900°F)

Cold Working

AISI 4140 alloy steel can be cold worked using conventional methods in the annealed condition.

Annealing

AISI 4140 alloy steel is annealed at 872°C (1600°F) followed by slowly cooling in the furnace.

Tempering

AISI 4140 alloy steel can be tempered at 205 to 649°C (400 to 1200°F) depending upon the desired hardness level. The hardness of the steel can be increased if it has lower tempering temperature. For example, tensile strength of 225 ksi cab be achieved by tempering at 316°C (600°F), and a tensile strength of 130 ksi can be achieved by tempering at 538°C (1000°F).

Hardening

AISI 4140 alloy steel can be hardened by cold working, or heating and quenching.