1.2083/420/4Cr13 Steel Flat for Injection Mould, Blowing Mould

Ningbo Ningshing Precision Machinery Group Co., Ltd.- Composition:Check Detailed Description

- Standard:AISI, ASTM, DIN, JIS, GB, BS

- Type:Special Steel Bar

- Technique:Hot Rolled

- Shape:Flat

- Surface Treatment:Black, Machined

Base Info

- Trademark:Ningbo Ningshing

- Transport Package:Nude Packing

- Specification:check detailed description

- Application:Tool Steel Bar

- Special Use:High-strength Steel Plate, Wear Resistant Steel, Silicon Steel, Cold Heading Steel, Free Cutting Steel, Mold Steel

- Model NO.:1.2083,420,4Cr13

- Origin:China

- Production Capacity:10000 Tons,Year

Description

Reamer, M7 1.3348 -- M42 1.3247 SKH59 √ M35 1.3243 SKH55 √ T1 1.3355 SKH2 T15 1.3202 -- T42 1.3207 SKH57 Annealing Note:

End-mill,

Hob, Cutter, Bite, Drill, Punch, Tap, Brooch

etc.

840 to 870°C

Slow controlled cooling in furnace at a rate of 10 to 20°C/hr down to approx. 600°C, further cooling in air. Hardness after annealing: max. 229 HB.

Stress relieving

Approx. 650°C

Slow cooling in furnace; intended to relieve stresses set up by extensive machining, or in complex shapes. After through heating, hold in neutral atmosphere for 1 - 2 hours.

Hardening

1000 to 1050°C / Oil, air

Holding time after temperature equalization: 15 to 30 minutes.

Obtainable hardness: 53-56 HRC

Tempering

100 to 200°C (212 to 392°F)

Slow heating to tempering temperature immediately after hardening / time in furnace

1 hour for each 20 mm of work piece thickness but at least 2 hours / cooling in air.

For average hardness figures to be obtained please refer to the tempering chart.

What we can offer?

We offer a wide range of steel products in a wide variety of dimensions and executions, acc.to the common international specifications or customerized.

Machining and heat treatment are available.

Also, we advise you in choosing the right materials.

Shape Available

Solid round bar

Flat bar

Square bar

Hexagon bar

Block

Plate

Sheet

Wire rod

Strip

1). √ means we have stoc.

2). Delivery Condition:

Smelting: EAF+LF+VD (+ESR).

Making: Hot rolled, Cold rolled, Forged, Cold Drawn.

Heat Treatment: Untreated, Annealing, N+T, Q+T.

Surface: Black, Peeled, Turned, Milled, Grinded, Polished.

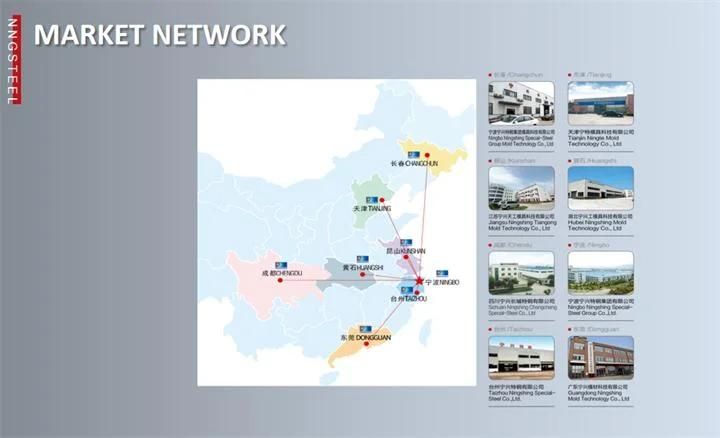

Q1: What is Ningbo Ningshing Precision Machinery Group Co., Ltd ?

A1: Ningbo Ningshing Precision Machinery Group Co., Ltd., formerly known as Ningbo Ningshing Special-Steel Group Co., Ltd., is the leading distributor of Special Steel, and also a professional mold base maker in China. Our business involves special steel trading, machining processing, mold base making, heat treatment, CNC machines manufacturing.

Q2: Are you a manufacturer or a trader?

A2: For Special Steel, we are the one of the leading distributors and service center in China. 9 warehouses with over 50,000 tons of regular stock. Our workshop has various kinds of equipments for sawing, milling, grinding, drilling etc.

For mold base, we are a professional manufacturer, with 24 sets of CNC machines, 3 axis and 5 axis, CMM for inspection. We produce medium-large sized mold base for plastic injection mold and die casting die.

Q3: How do you control the quality of steels?

A3: Firstly, we have very close and deep relationship with Chinese Prime Mills, choose supplier carefully, and regard them as the long term business partner. Based on the long term cooperation, we concentrate on special steel business and expand the market step by step. Secondly, we have own technical center which is formed by the experienced engineers and technicians whom ever worked for prime mills. We control the quality in production process, in-out warehouse.

Q4:: Which kind of processing can you do?

A4: We do machining processing like cutting, milling, grinding, turning, peeling, drilling, CNC machining. Meanwhile, we do vacuum heat treatment for die and mold.