Dx51d Z275 Galvanized/Galvanised Steel Sheet/Plate Zinc Iron Roofing Sheet Dx53D Z150 24 Gauge 4X8 Metal Roof Sheet

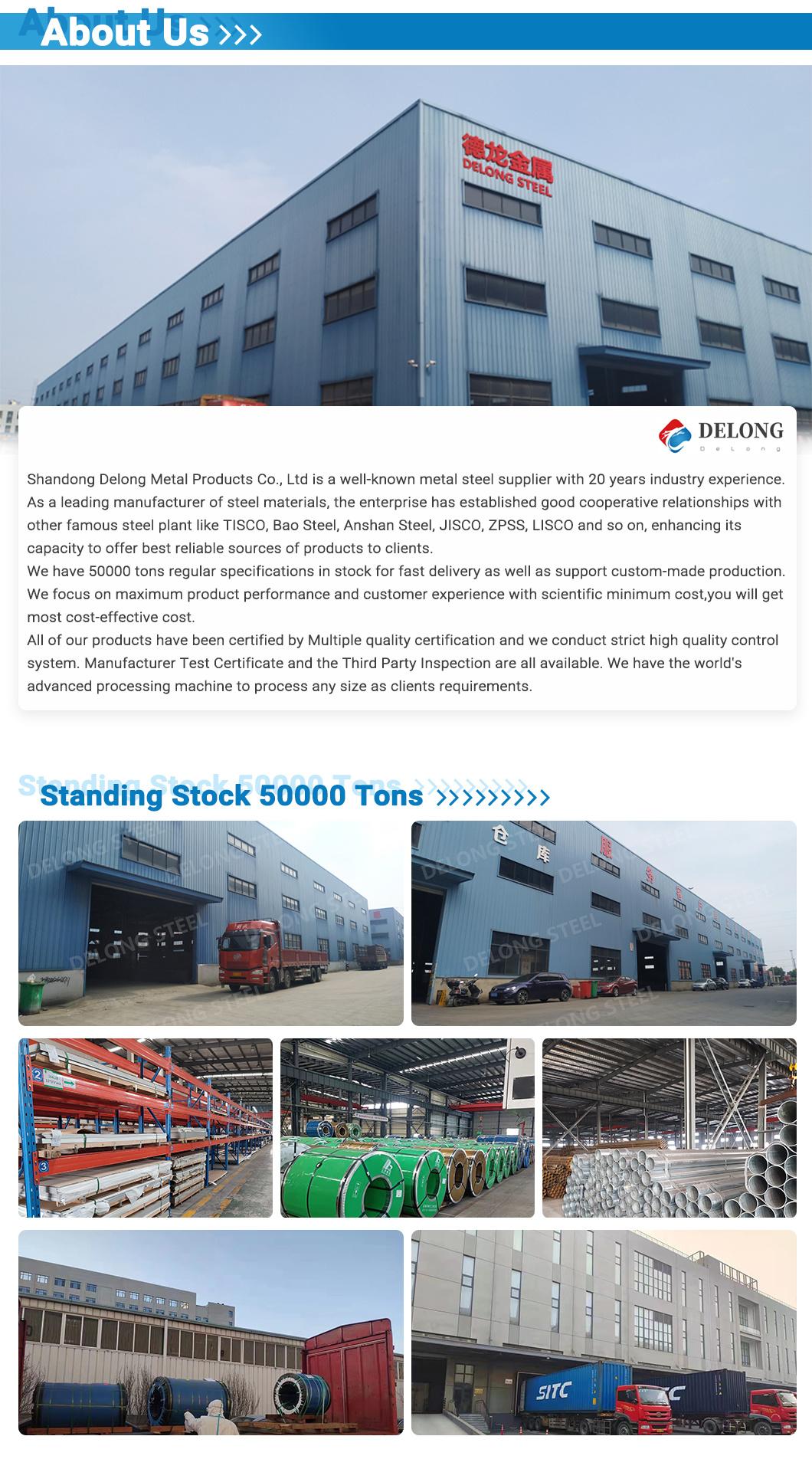

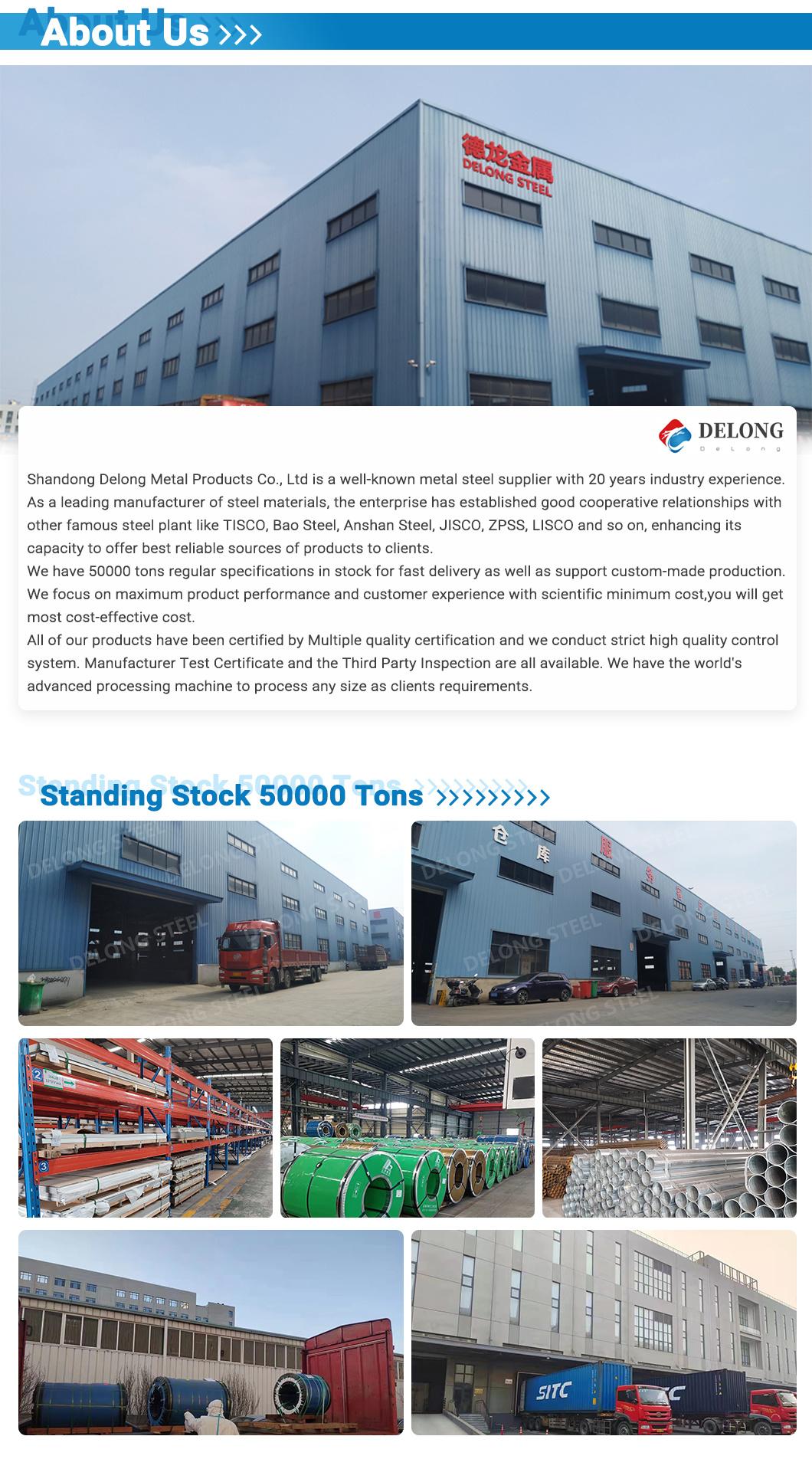

Shandong Delong Metal Products Co., Ltd.- Standard:ASTM, AISI, GB, JIS, DIN, BS

- Type:Steel Plate

- Warranty:1year

- After-sales Service:1year

- Certification:ISO, RoHS, IBR

- Surface Treatment:Galvanized

Base Info

- Width:30mm-2050mm,as Required

- Length:1000-8000mm.as Required

- Grade:SGCC Dx51d+Z, SGCC,Sgch,SPCC,Spcd,Spce

- Surface:Cheomated,Non-Chromated,Non Oiled,Oiled,Anti Finge

- Spangle:Regular Spangle, Minimal Spangle, Zero Spangle

- Tolerance:1%

- Delivery Time:7-14 Days

- Stock:Stock

- Zinc Coating Weight:30G,M2-600G,M2,Double Side

- Special Use:Cutting Tools, Measuring Tools, Cutters in Common Steel, High-strength Steel Plate, Wear Resistant Steel

- Application:Mold & Dies, Ship Plate, Boiler Plate, Container Plate, Flange Plate

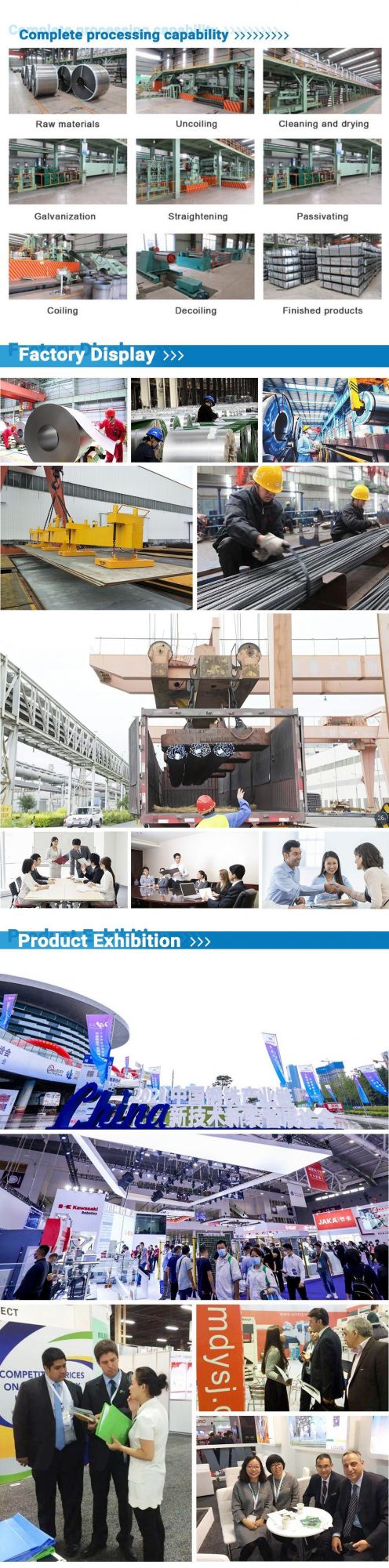

- Technique:Hot Rolled ,Cold Rolled

- Model NO.:Galvanized steel sheet,plate

- Temper:Full Hard, Half Hard, Sort

- Transport Package:in Bulk, in Bunddle, in Water Proof Plastic Wrrapp

- Specification:As required

- Trademark:DELONG

- Origin:Shandong

- HS Code:7208519000

- Production Capacity:7000 Tons,Month

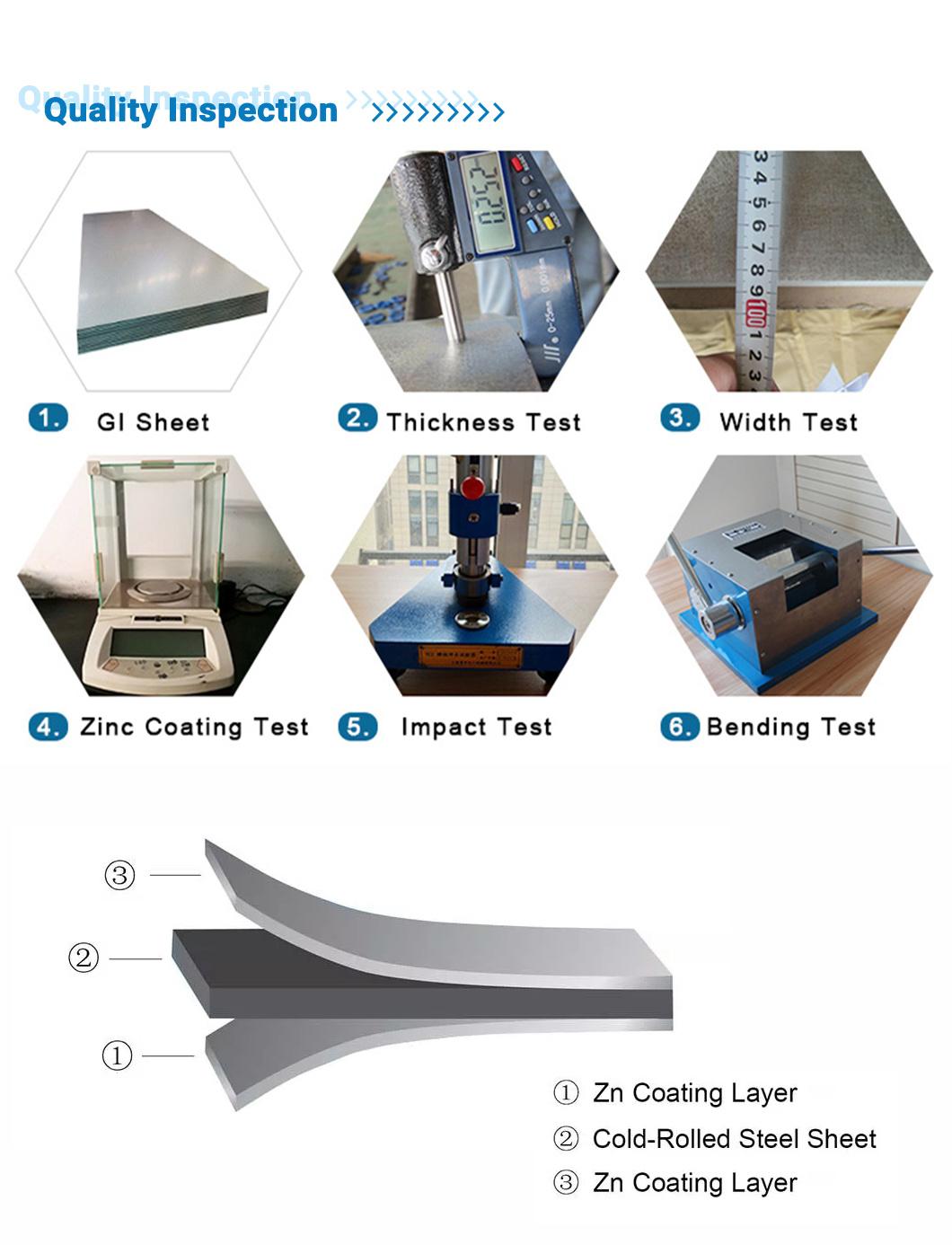

Description

Container size20ft GP: 5898mm(Length)x2352mm(Width)x2393mm(High) 40ft GP: 12032mm(Length)x2352mm(Width)x2393mm(High) 40ft HC: 12032mm(Length)x2352mm(Width)x2698mm(High) Gauge mm Inches 8 4.27 0.1681 9 3.89 0.1532 10 3.51 0.1382 11 3.13 0.1233 12 2.75 0.1084 14 1.99 0.0785 16 1.61 0.0635 18 1.31 0.0516 20 1.01 0.0396 21 0.93 0.0366 22 0.85 0.0336 23 0.78 0.0306 24 0.7 0.0276 25 0.63 0.0247 26 0.55 0.0217 27 0.51 0.0202 28 0.47 0.0187 30 0.4 0.0157 DX51D+Z DX51D+Z SGCC CS Type C DX52D+Z DX52D+Z SGCD1 CSTypeA.B DX53D+Z DX53D+Z SGCD2 FS Type A, B DX54D+Z DX54D+Z SGCD3 DDS Type C S250GD+Z S250GD+Z SGC340 SS255 S280GD+Z S280GD+Z SGC400 SS275 S320GD+Z S320GD+Z - - S350GD+Z S350GD+Z SGC440 SS340 Class4 S550GD+Z S550GD+Z SGC590 SS550 Class2

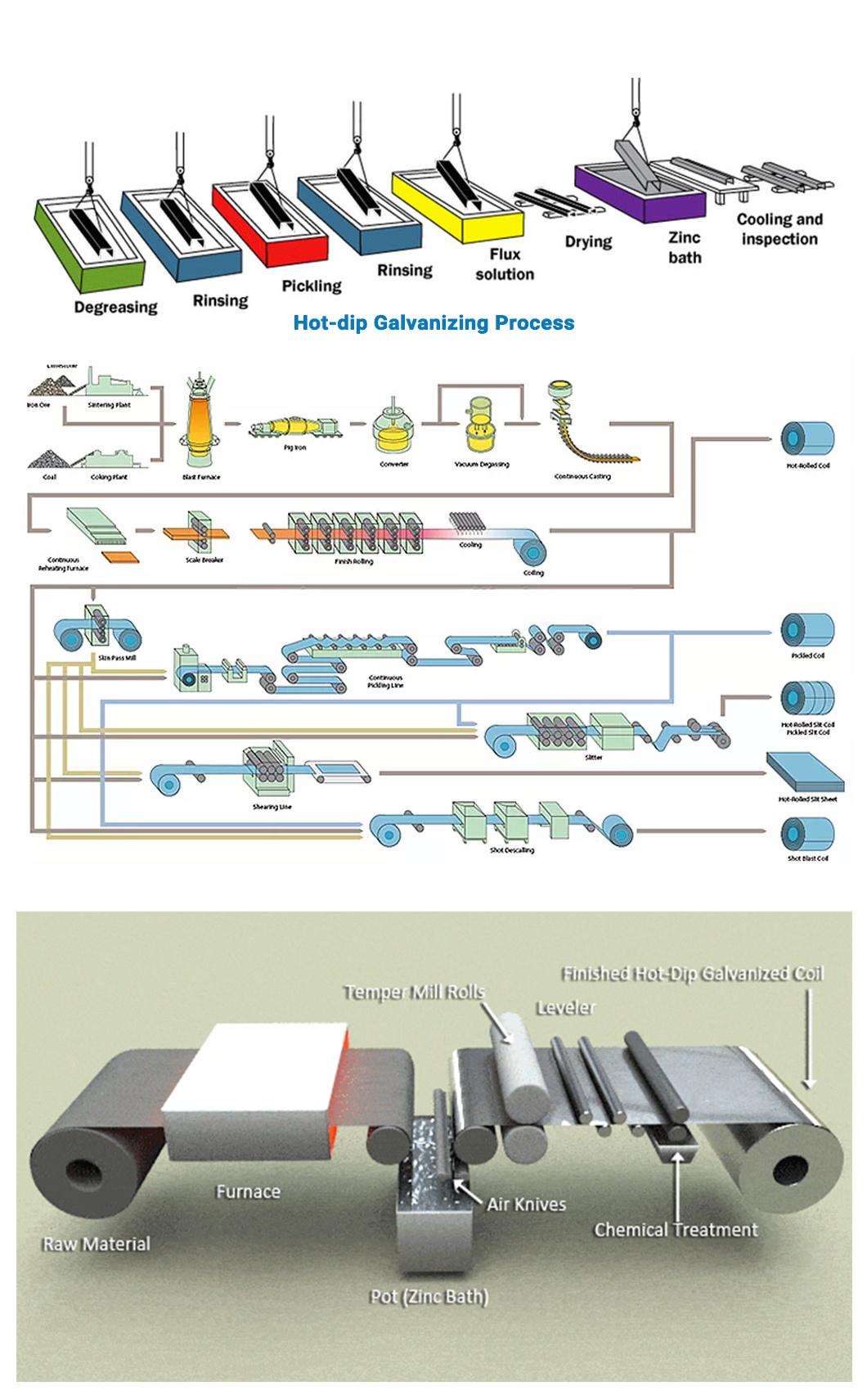

Hot-dip Galvanized Steel Sheet

Hot-dip Galvanized Steel Sheet

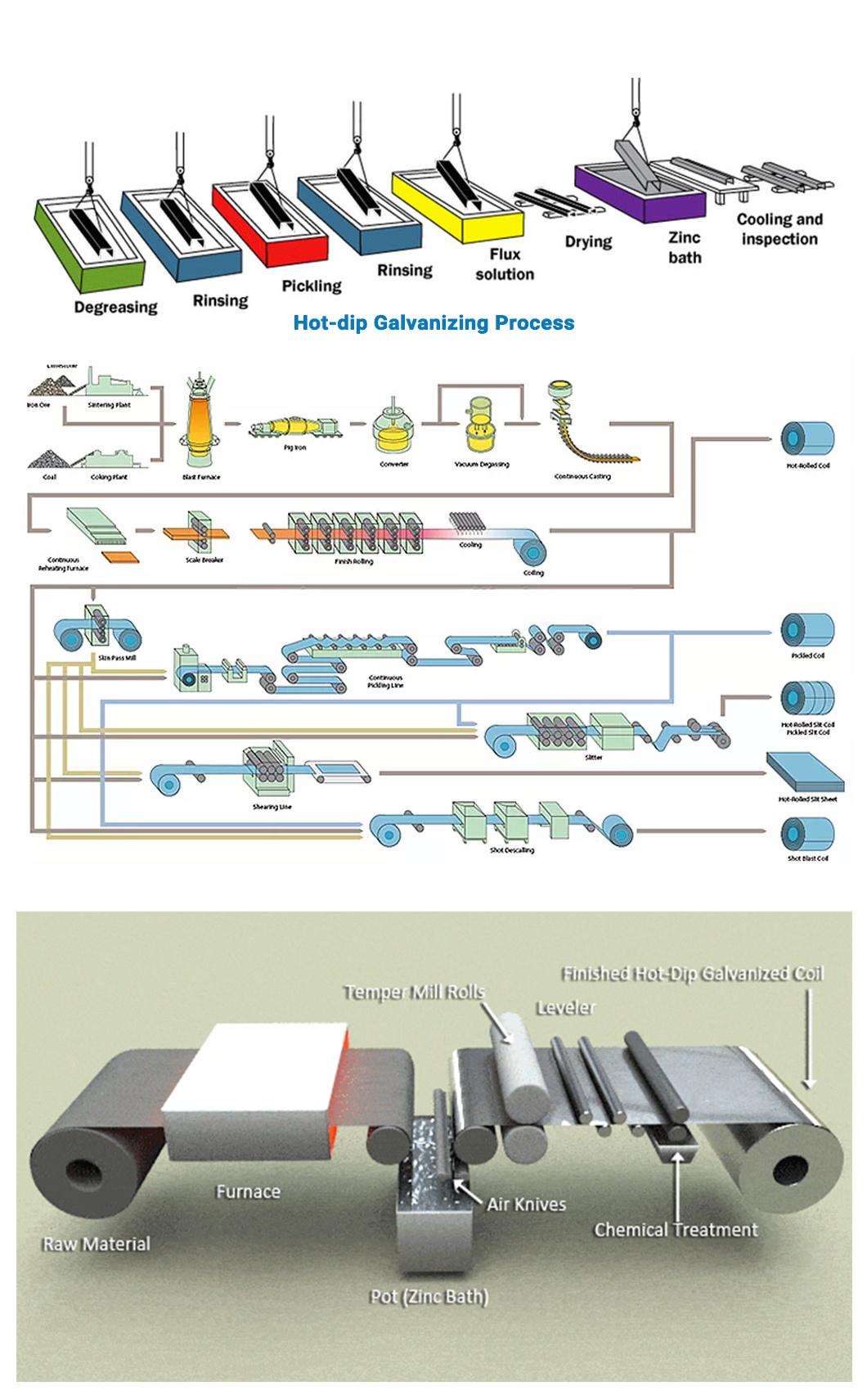

Hot-dip galvanized sheet is made by immersing the steel sheet in a molten zinc bath at about 500 °C to attach a zinc layer to the surface. This is the continuous galvanizing process. It will form a protective zinc layer on the surface so that it has good paint adhesion and weldability. It is the most widely used and cost-effective method to prolong the service life of steel sheets. .

Electro-galvanized Steel Sheet

Electro-galvanizing, also known as cold galvanizing, uses electrolysis to form a uniform and dense layer on the surface of the metal. The anti-corrosion zinc layer can protect steel parts from oxidation corrosion. Also, it can meet decorative purposes. But the zinc layer of the electro-galvanizing steel sheet is only 5-30 g/m2. So its corrosion resistance is not as good as hot-dip galvanized sheets.

Difference Between Hot-Dip and Electro-galvanized Steel Sheets

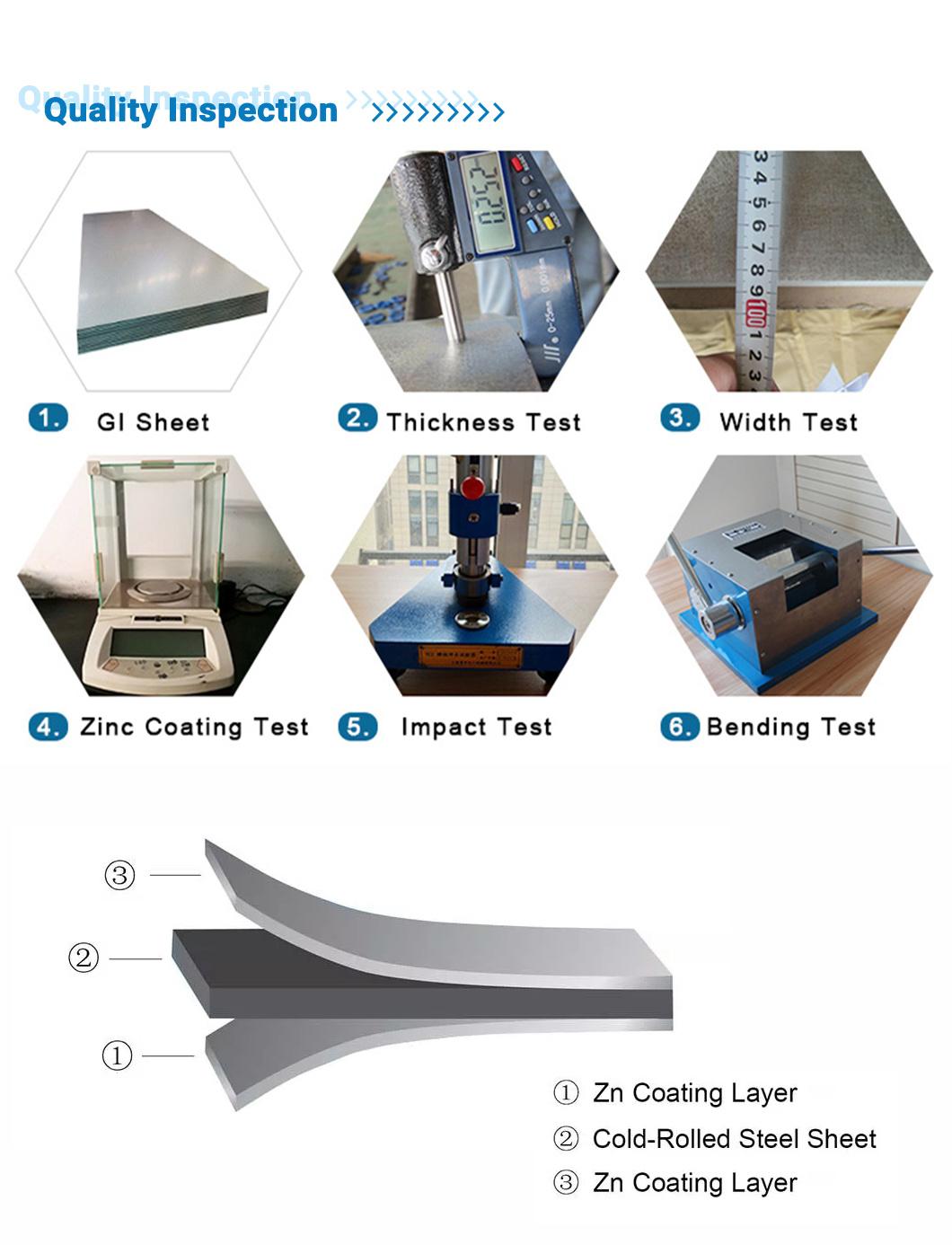

Anti-corrosion

The zinc coating thickness is one of the most important factors matters corrosion resistance. The greater the zinc layer thickness, the better the corrosion resistance. Generally, the thickness of hot-dip zinc coating is more than 30 g/m2, or even as high as 600 g/m2. While the electro-galvanized zinc layer is only 5~30 g/m2 thick. So the former steel sheet is much more corrosion resistant than the latter one. At Wanzhi Steel, the maximum zinc layer is 275 g/m2 (z275 galvanized steel sheet).

Method of Operation

The hot-dip galvanized steel sheet is galvanized in a molten zinc bath at about 500 degrees, while the electro-galvanized steel sheet is processed at room temperature by electroplating or other methods. That's why electro-galvanizing also refers to the cold galvanizing process.

Surface Smoothness & Adhesion

The surface of the electro-galvanized steel sheet looks smoother than hot-dip galvanized sheets. But its adhesion is not as good as that of the hot-dip galvanized sheet. If you want only one side galvanized, you can choose the electroplating method. However, if adopting hot-dip galvanizing, both sides are coated with a zinc layer fully.

Types of GI Sheets

Types of GI Sheets

In terms of the manufacturing process, we divide it into hot-dip galvanized steel sheets and electro-galvanized steel sheets. Hot-dip galvanized sheet is mainly used in construction, home appliances, automobiles, light industry, and other industries. Below are more details for your reference.

Hot-dip Galvanized Steel Sheet

Hot-dip Galvanized Steel SheetHot-dip galvanized sheet is made by immersing the steel sheet in a molten zinc bath at about 500 °C to attach a zinc layer to the surface. This is the continuous galvanizing process. It will form a protective zinc layer on the surface so that it has good paint adhesion and weldability. It is the most widely used and cost-effective method to prolong the service life of steel sheets. .

Electro-galvanized Steel Sheet

Electro-galvanizing, also known as cold galvanizing, uses electrolysis to form a uniform and dense layer on the surface of the metal. The anti-corrosion zinc layer can protect steel parts from oxidation corrosion. Also, it can meet decorative purposes. But the zinc layer of the electro-galvanizing steel sheet is only 5-30 g/m2. So its corrosion resistance is not as good as hot-dip galvanized sheets.

Difference Between Hot-Dip and Electro-galvanized Steel Sheets

Anti-corrosion

The zinc coating thickness is one of the most important factors matters corrosion resistance. The greater the zinc layer thickness, the better the corrosion resistance. Generally, the thickness of hot-dip zinc coating is more than 30 g/m2, or even as high as 600 g/m2. While the electro-galvanized zinc layer is only 5~30 g/m2 thick. So the former steel sheet is much more corrosion resistant than the latter one. At Wanzhi Steel, the maximum zinc layer is 275 g/m2 (z275 galvanized steel sheet).

Method of Operation

The hot-dip galvanized steel sheet is galvanized in a molten zinc bath at about 500 degrees, while the electro-galvanized steel sheet is processed at room temperature by electroplating or other methods. That's why electro-galvanizing also refers to the cold galvanizing process.

Surface Smoothness & Adhesion

The surface of the electro-galvanized steel sheet looks smoother than hot-dip galvanized sheets. But its adhesion is not as good as that of the hot-dip galvanized sheet. If you want only one side galvanized, you can choose the electroplating method. However, if adopting hot-dip galvanizing, both sides are coated with a zinc layer fully.

Types of GI Sheets

Types of GI SheetsIn terms of the manufacturing process, we divide it into hot-dip galvanized steel sheets and electro-galvanized steel sheets. Hot-dip galvanized sheet is mainly used in construction, home appliances, automobiles, light industry, and other industries. Below are more details for your reference.