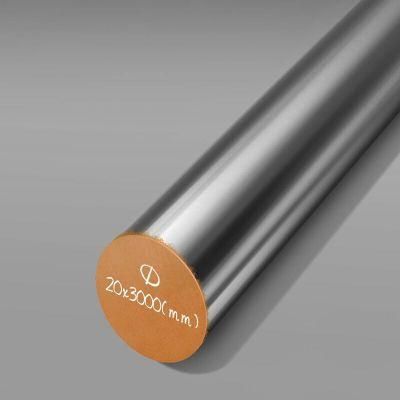

AISI/Sea 420ss 4Cr13 X38c13 Mold Steel Round Bar Die Steel Mould Rod/Black Bar 3m, 6m, 12m

Shanghai Bozhong Metal Group Co., Ltd.- Type:Round

- Standard:AISI, ASTM, DIN, JIS, GB, BS

- Composition:Stainless Steel Scrap

- Technique:Cold Rolled

- Shape:Bar

- Surface Treatment:Black

Base Info

- Special Use:High-strength Steel Plate, Wear Resistant Steel, Silicon Steel, Cold Heading Steel, Free Cutting Steel, Mold Steel

- Application:Die Steel Bar

- Specification:R: dia60-610mm; F20-300X100-610mm

- Trademark:Bozhong

- Origin:China

- Production Capacity:50000tons,Month

Description

Basic Info.

Special Use High-strength Steel Plate, Wear Resistant Steel, Silicon Steel, Cold Heading Steel, Free Cutting Steel, Mold Steel Application Die Steel Bar Specification R: dia60-610mm; F20-300X100-610mm Trademark Bozhong Origin China Production Capacity 50000tons/MonthProduct Description

General Information:Stainless martensitic steel with a high hardenability, good polishing properties, excellent resistance to corrosion and hot oxidation.

Application:

Used for plastic moulds, particularly for acid aggressive plastics (e.g. acetate and PVC), or plastics containing abrasive fillers. Suited for the manufacture of glass, such as moulds of optical products.

Comparable Standards:

| AISI/SAE | DIN | W.Nr. | AFNOR | JIS | BS | SIAU | GB,YB |

| - | 40Cr13 | 1.2083 | - | SUS420J2 | - | - | 4Cr13 |

Chemical Analysis (%):

| C | Mn | Si | Cr | Ni | Mo | P | S |

| 0.36-0.42 | ≤1.00 | ≤1.00 | 12.5-14.5 | - | - | ≤0.03 | ≤0.03 |

Heat treatment

Annealing:

-Heat to 750~800°C, with hold at minimum rate for 3 hours.

-Furnace cooling.

Stress relieving:

To be carried out after machining and before the final heat treatment.

Heating to 600~650°C for 2 hours.

Hardening:

Preheating to 600~700°C;

- Austenitizing at 990~1040°C

- Oil or thermal bath cooling at 500~550°C, then oil cooling according to the steel shape and size.

Quenched hardness: HRC 52~56

Tempering:

To be carried out after hardening according to the required hardness; at 170-270 °C in order to match hardness and resistance to corrosion; permanence for at least 2 hours;

Tempering must be repeated at least twice at a temperature 30 °C lower than the previous. Cooling in air.