Minimal Surface Relief Cracks Smooth Overlay Plate

Qingdao Hart Industrial Technology Co., Ltd.- After-sales Service:Provide Reasonable Solutions Within 12 Hours

- Warranty:as Required

- Type:Steel Plate

- Standard:ASTM

- Certification:ISO

- Surface Treatment:Coated

Base Info

- Model NO.:HART-P-200

- Technique:Hot Rolled

- Application:Container Plate

- Special Use:Wear Resistant Steel

- Stock:Stock

- Wear Resistance:High Wear Abrasion Resistance

- Flatness Tolerance:±3mm,M

- Impact Resistance:Medium

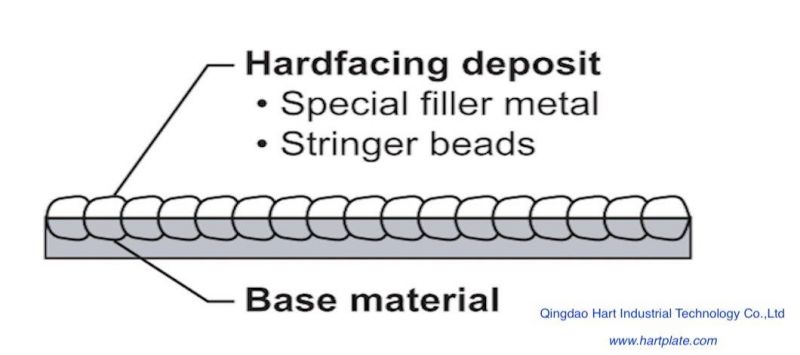

- Hardfacing Layer:High Chromium High Carbide Overlay

- Transport Package:Steel Frame or as Required Package

- Specification:Stock Thickness: From 3+3 to 30+30mm

- Trademark:HART Industry

- Origin:Shandong, China

- HS Code:7210500000

- Production Capacity:1000 Pieces Per Month

Description

N>5

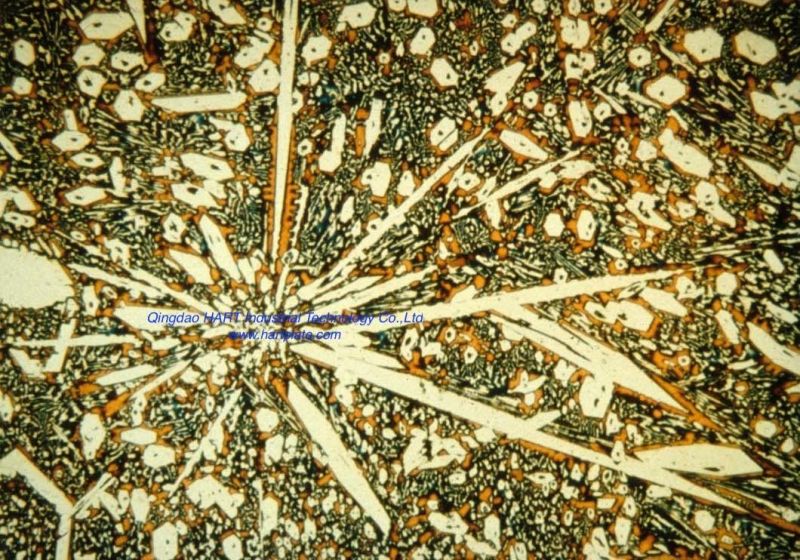

8. Microstructure:

Composed of a high proportion of extremely hard primary M7C3 chromium rich carbides dispersed in a ductile eutectic austenite matrix.

Maintains 30% to 50% of primary carbides to provide a good wear resistance and homogenous bonding.

9. Typical Applications:

HART-P-100 Plate is widely used in the mining, power generation(Coal), cement, dredging, steel production, waste handling, glass production, and pulp and paper industries. Some specific applications include:

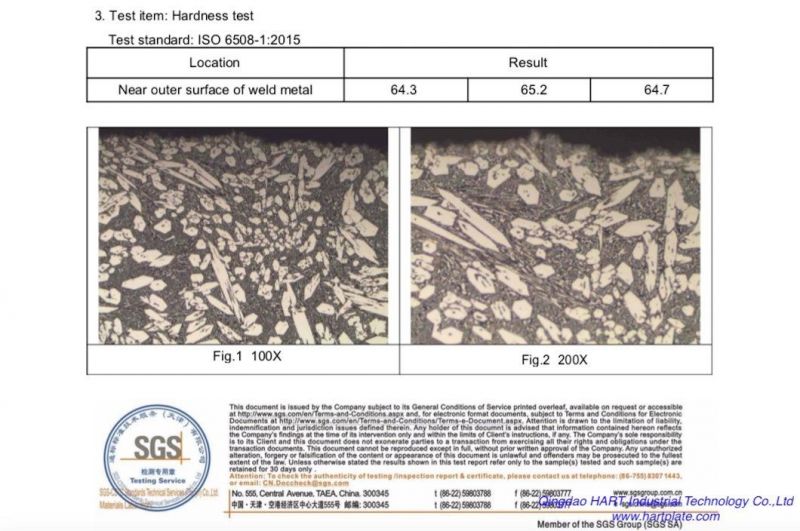

10. Wear properties of HART-P-100 (ASTM G65 and SGS test report)

*ASTM G65 is a standard test measuring sliding abrasion resistance using a dry sand/rubber wheel apparatus.

11. Service

1. Can be cut by plasma, laser, water jet, arc gouge, and abrasive saw cutting;

2. Cannot be cut by oxy-fuel.

1. Use 480 MPa (70 ksi) or 560 MPa (80 ksi) consumable to join base metal;

2. After welding, joint should be capped by overlay for wear protection.

1. Not machinable by conventional methods;

2. Can be finished by grinding only;

3. Countersunk holes can be precisely produced by EDM (Electrical Discharge Machining).

1. Commonly formed with overlay to the inside;

2. For pipes with diameters smaller than 0.6m (24"), hardfacing pipe recommended instead of pipes fabricated from hardfacing plate.

1. When drilling, the distance between two holes should be at least 15mm (5/8''); otherwise, the partition may not be strong enough and can crack;

2. The minimum diameter of holes should be equal to the thickness of the plates. For thicker plates with a total thickness over 20mm (3/4''), the minimum diameter should be 1.5 times the thickness of the plate.

12. Testing and quality control

We documented how the product properties are tested in order to make sure the overlay plates fulfil the specified product properties. Including documentation on 3d party's quality system if calibration and testing is performed by 3d party.

13. Packing and loading