1.2083 420 S136 4Cr13 Special Corrosion-Resistant Alloy Tool Steel for Die & Tool

Guangzhou Changfeng Steel Co., Ltd.- Standard:DIN, JIS, AISI, ASTM, GB, BS

- Technics:Hot Rolled

- Application:Die Steel Bar

- Surface:Polished

- Alloy:Alloy

- Special Use:High-strength Steel Plate, Wear Resistant Steel, Mold Steel

Base Info

- Model NO.:4Cr13, 420, S136, 1.2316

- Certificate:ISO,Mill Certificate

- Heat Treatment:Annealing,Q+T

- Technique:Ef,Eaf+Lf+Vd,ESR

- Ut Test Standard:Sep1921-84 Class3 C,C to D,D

- Payment:30% deposit, balance by L,C at sight or T,T

- Sample:Free

- Lead time:7-15 days

- Stock:Available

- Hardness:30-36HRC

- Thickness:12-150mm

- Width:205-2000mm

- Length:2000-6000mm

- Steel mill:Bao Steel

- Shape:Flat, round

- Edge:2 or 4 side cutting

- Transport Package:Standard Export Packing or Customized

- Specification:12-150*205-2000*2000-6000mm

- Trademark:CF STEEL

- Origin:China

- HS Code:7225400000

- Production Capacity:1000t,Month

Description

Supply states: 30-36HRC

Features

1.Good corrosion resisting

2.High cast polarimetry

3.Good wear resistance

4.Excellent machining property

5.Quenching with excellent stability

Advantages

1.The mold manipulation or storage in humid environment, do not need special protection.

2.Lower production costs due to the mold cooling water from corrosion (unlike ordinary tool steel), heat transfer characteristics, cooling efficiency during the lifetime of the mold to maintain stability and ensure the constancy of the forming die time.

3.STAVAX ESR (S-136) is recommended for all molds, due to its special nature, it is more suitable for the needs of specific environments.

4.Resistant injection molding material or work and must be stored in a wet environment, mold corrosion, rust on the use of corrosive PVC, acetic acid salts.

5.Abrasion wear resistance using large injection molding material (including thermoset injection molding) or the requirements of the mold have longer working hours, such as electronic parts, discard-style meal knives, and other utensils.

6.High surface smoothness of the production of optical products such as cameras, sunglasses, chemical equipment and plastic products.

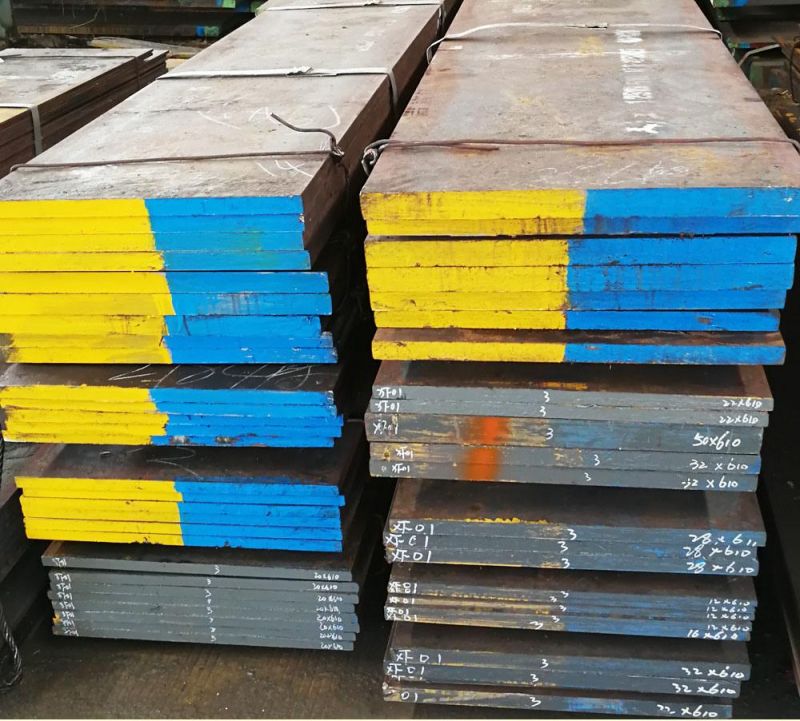

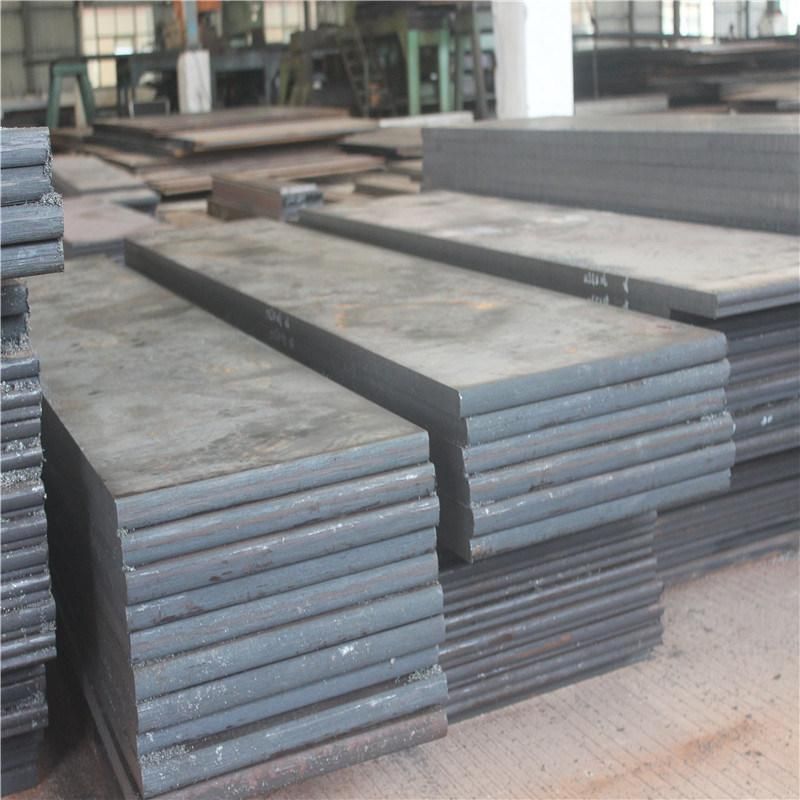

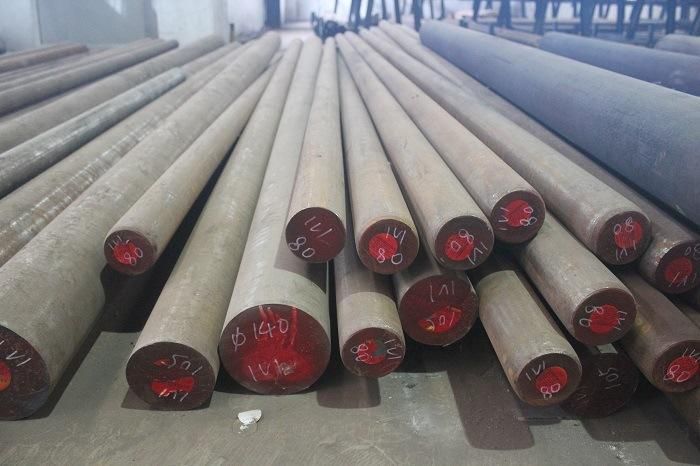

Picture show

1.2083 420 S136 4Cr13 Special Stainless Plastic Mould Steel Bar

1.2083 420 S136 4Cr13 Special Stainless Plastic Mould Steel Round Bar

About US

Guangzhou Changfeng Steel Co., Ltd. is a professional special steel company, which specializing in this line in China since 2005. Our main products are Plastic Mould Steel, Hot Work Mould Steel, Cold Work Mould Steel, Alloy Structural Steel, Tool Steel, Stainless Steel, Carbon Steel and Forged Block.

To ensure provide high quality products to customers, we have close cooperation with many Chinese first class special steel enterprises, including Baosteel Group, Dongbei Special Steel, Changcheng Special Steel, Hongsheng Heavy Industry, Xingcheng Special Steel and Daye Special Steel.

FAQ

Q: Are you a manufacturer or merely a trader?

A: We are group of companies and owned manufacturer bases and trading company. We specialized in plastic mould steel,hot work mould steel,cold work mould steel,alloy steel for mechanical,high speed steel, etc. All material are with high quality and competitive price.

Q: How do you guarantee the quality of your product?

A: Firstly, we can provide the certificates from the third party, such as SGS, CE,ISO if you need. Secondly, we have a complete set of inspection system and every process is checked by QC. Quality is the lifeline of enterprise survival.

Q: Delivery time?

A: We have ready stock for most of material grades in our warehouse. If the material don't have stock, the delivery lead time is about 30-50days (depend on the quantity)after receiving your prepayment or firm order.

Q: What is the payment term?

A: T/T or L/C or Trade Assurance.

Q: Can we visit your company and factory?

A: Yes, warmly welcome! We can book the hotel for you before you come to China and arrange our driver to our airport to pick you up when you come.

Why Choose Us

1. Competitive price and quality from our own factory

2. Approved by ISO9001, CE, SGS every year

3. Best service with 24 hours reply

4. Flexible payment with T/T,L/C , Trade Assurance

5. Smooth production ability(1000tons/month)

6. Quick delivery and standard exporting package

7. OEM/ODM