1.2312 Nak80 P20+S/P21 Forged Qt Milled Surface Plastic Mould Steel P21 Steel Mirror Surface

Guangdong Shenghe International Trade Co., Ltd.- Standard:DIN, JIS, AISI, ASTM, GB, BS

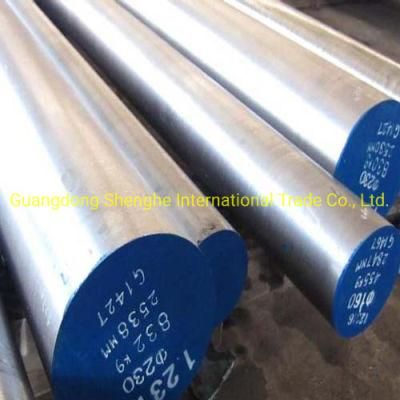

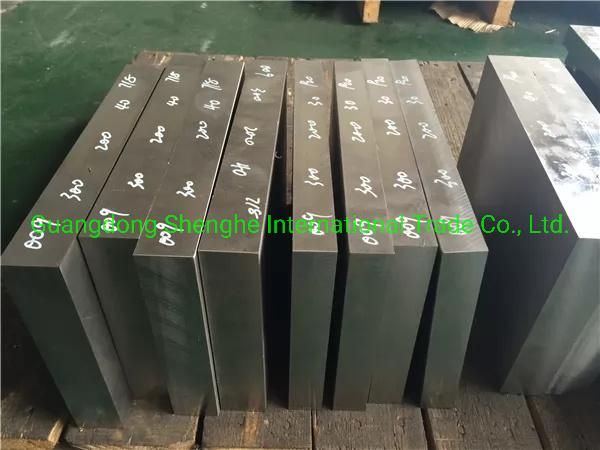

- Technics:Forged

- Application:Die Steel Bar

- Surface:Galvanized

- Alloy:Alloy

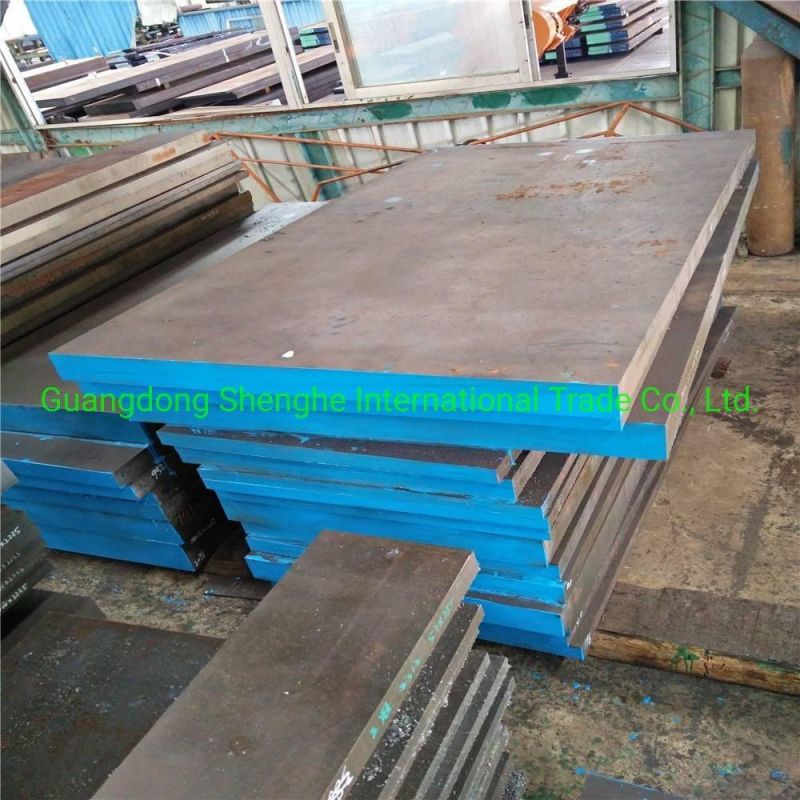

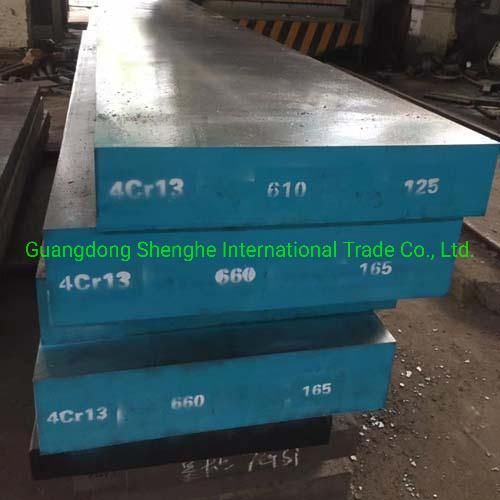

- Special Use:High-strength Steel Plate, Wear Resistant Steel, Silicon Steel, Cold Heading Steel, Free Cutting Steel, Mold Steel

Base Info

- Model NO.:SH2311

- Transport Package:Wood Brick, Wirerope

- Specification:1*20Gp, 1*40Gp

- Trademark:SH

- Origin:Dongguan City

- HS Code:7228300000

- Production Capacity:5000 Tons

Description

4.Product Technique:

Introduction:

Low-carbon mold steels or group P steels are of different types that include P2, P3, P4, P5, P6, P20, and P21 steels. Chromium and nickel are the main alloying elements found in group P steels.

P20 tool steels are nitrided or carburized. These steels are capable of being machined into complex and large dies and molds. P20 steels are mostly used in the carburized condition. The presence of chromium and nickel enhances the toughness and hardness of P20 steels.

Fabrication and Heat Treatment:

5.Feature:

1.Vacuum degassing refining processing steel purity, suitable for polishing or etch processing plastic mold.

2. In pre-harden state delivery, no need for heat treatment can be directly used for mold processing, shorten the construction.

3. After heat treatment machining and polishing performance is good, the nitriding treatment, can be suitable for chrome plating surface treatment, such as material is the qualitative hardness is uniform (400mm thick), good toughness and good machining performance.

4.Good hardness uniformity and polishing property, good machining properties.

5.Good integral mechanical performance under high temperatures.

6.Good heat-resistance and fatigue-resistance.

7. Pre-hardened to HRC30-36 can be directly used for mold processing, shorten the construction period.

FAQ

1.What's your advantage?

A: Competitive price and delivery on time , large quantity in stock ,we can make sure very fast shipment out

2. How I believe you?

A : Visit us office or factory, or 3rd part inspection the goods before shipment

3.Can you give warranty of your products?

A: Yes .All products quality warranty more than 12 month

4. Can I visit you?

A: Sure,welcome to visit us at any time.

5.How about the delivery time?

A: plates and coils usually 3-7 days , the strip usually 15 days , the pipe usually 15 days for welded pipe , and 30 days for the seamless pipe , pipe fittings usually 15-20 days , the flanges usually 15 days

6.what kind of payment does your company support?

A: T/T, 100% L/C at sight, Cash, Western Union are all accepted

7. Do you have sample and sample free ?

A: Yes , we have many samples in hand and one sample is free for you

Delivery Time: 20 days after the deposit confirm.

Shipment: By boat, usually takes 30~45 days to arrive your plant.