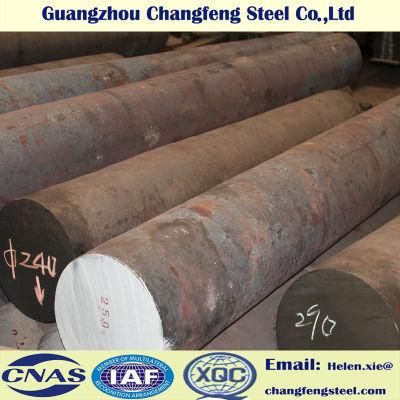

Stainless Annealing Alloy Steel Round Bar 1.2080 D3 SKD1 Cr12

Guangzhou Changfeng Steel Co., Ltd.- Type:Alloy Steel Bar

- Standard:AISI, ASTM, GB, JIS, DIN, BS

- Technique:Hot Rolled

- Application:Tool Steel Bar, Die Steel Bar

- Surface Treatment:Black, Grinded, Machined

- Alloy:Alloy

Base Info

- Model NO.:1.2080, D3, SKD1,Cr12

- Special Use:Used for High Quality Wear Cold-Punching Mould

- Grade Number:SKD1, D3, Cr12 ,1.2080 Mould Steel

- Grade:1.2080, D3, SKD1,Cr12

- Hardness:Annealed Hbs248 Max

- Dimensions:70mm~410mm

- Length:80mm~410mm

- Shape:Round Bar

- Payment:30% Deposit,Blance by L,C at Sight or T,T

- Certificate:ISO,Mill Certificate

- Delivery Quantity:Include MOQ

- Transport Package:Export Standard Packing or Customers′demand

- Specification:According to customer requirements

- Trademark:CF STEEL

- Origin:China

- HS Code:7228400000

- Production Capacity:1000t,Month

Description

PlateThickness(mm) Width (mm) Length (mm) Max:800 Max:1000 Max:6000

6, Delivery date

For abundant stock, 15-20 days.

For customized products, 30-50 days.

7, Packing: Standard export packing or As per request

8, About Us

Heat Treatment

D3 tool steel requires hardening and tempering to achieve maximum properties. For maximum accuracy, the parts of D3 tool steel should be stress relieved after roughing operations. Stress should be relieved at 648°C (1200°F) for one hour and cooled slowly.

Annealing

Heat D3 tool steels uniformly to 850-870°C, soak thoroughly, then slow furnace cool at a rate of not more than 25°C per hour to 650°C. The parts may then be air cooled. This should result in a maximum hardness of brinell 248.

Tempering

The D3 cold work steel should be cooled to room temperature and should be tempered immediately. The parts should be placed in the tempering furnace and increased slowly to the desired tempering temperature. Tempering for 1 hour per inch of thickness is required.

Hardening

D3 tool steel is extremely sensitive to overheating during hardening - do not overheat.

Pre heat slowly to 800-850°C, the raise rapidly to 950-970°C and soak until completely equalised. Quench in oil.

6, Delivery date

For abundant stock, 15-20 days.

For customized products, 30-50 days.

7, Packing: Standard export packing or As per request

8, About Us

Heat Treatment

D3 tool steel requires hardening and tempering to achieve maximum properties. For maximum accuracy, the parts of D3 tool steel should be stress relieved after roughing operations. Stress should be relieved at 648°C (1200°F) for one hour and cooled slowly.

Annealing

Heat D3 tool steels uniformly to 850-870°C, soak thoroughly, then slow furnace cool at a rate of not more than 25°C per hour to 650°C. The parts may then be air cooled. This should result in a maximum hardness of brinell 248.

Tempering

The D3 cold work steel should be cooled to room temperature and should be tempered immediately. The parts should be placed in the tempering furnace and increased slowly to the desired tempering temperature. Tempering for 1 hour per inch of thickness is required.

Hardening

D3 tool steel is extremely sensitive to overheating during hardening - do not overheat.

Pre heat slowly to 800-850°C, the raise rapidly to 950-970°C and soak until completely equalised. Quench in oil.