ASTM A556 Gr. A2 Gr. B2 Gr. C2 Seamless Cold Drawn Carbon Steel Feedwater Heater Tubes

Guangzhou Kingmetal Steel Industry Co., Ltd.- Type:Seamless

- Technique:Cold Drawn

- Material:Carbon Steel

- Surface Treatment:Black

- Usage:Pipeline Transport, Boiler Pipe

- Section Shape:Round

Base Info

- Model NO.:EYST

- Thickness:1.2 - 9.5mm

- Length:1-12m

- Delivery Time:15-30 Days After Down Payment

- Standard or Not:Standard

- Alloy or Not:Is Alloy

- Secondary or Not:Non-Secondary

- Price Term:Fob,CIF,CNF

- Payment:L,C,T,T

- MOQ:as Requested

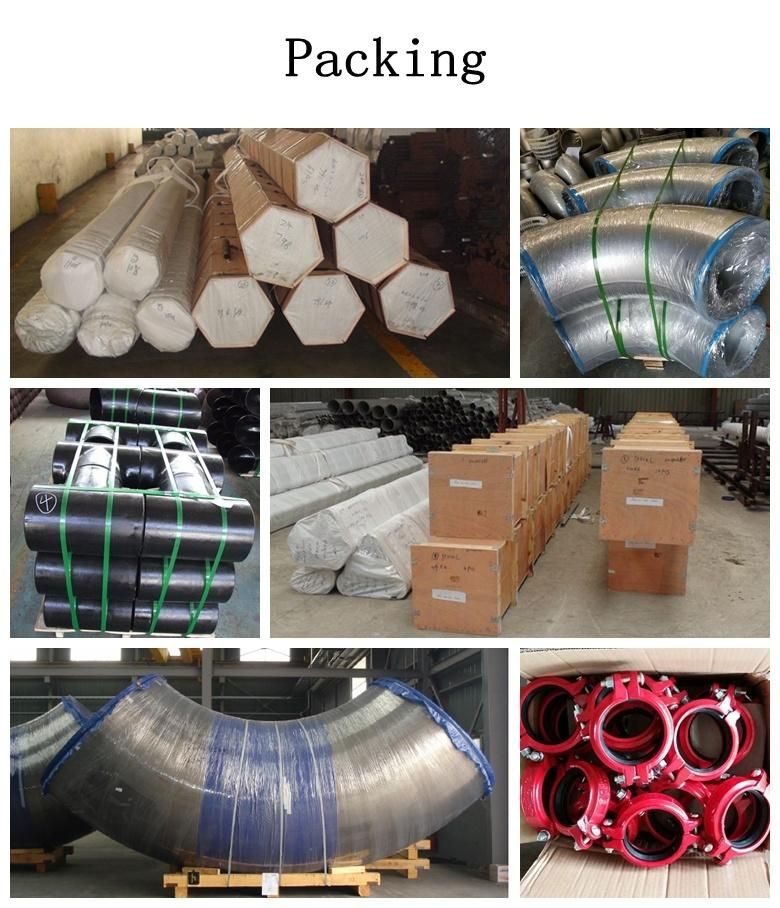

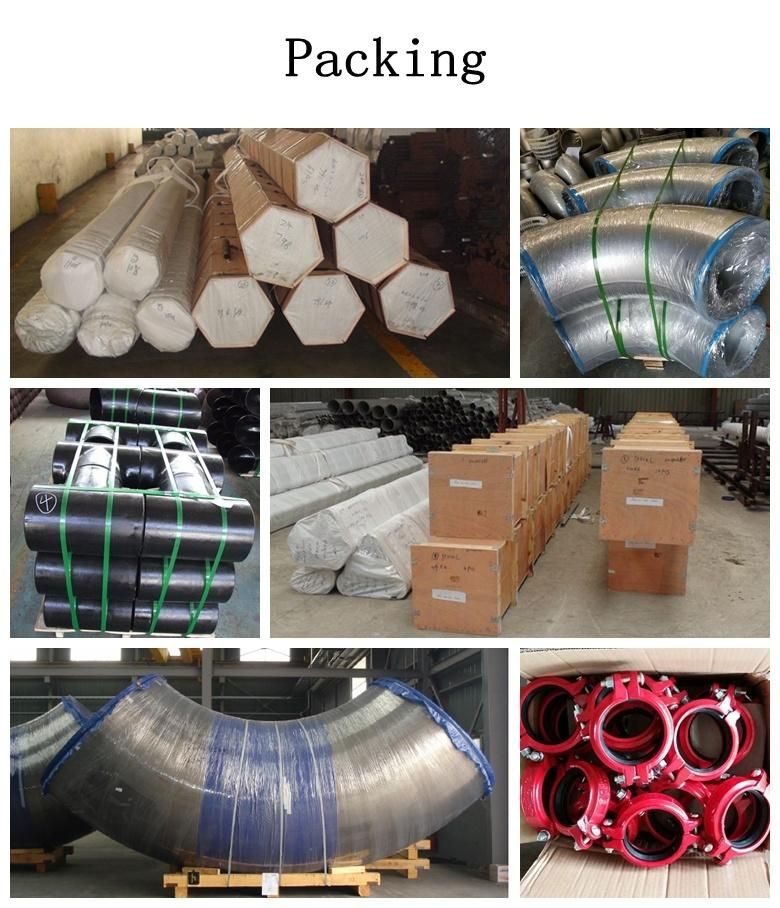

- Transport Package:in Bundles

- Specification:15.9- 139.8mm

- Trademark:Kingmetal

- Origin:China (Mainland)

- HS Code:730419

- Production Capacity:20000 Tons,Month

Description

A106 GR.A/GR.B/GR.C

A179/A192

A210 GR.A1/GR.C

A209 GR.T1/GR.T1a/GR.T1b

A213 T1/T2/T5/T11/T12/T22

A335 GR.1/GR.6

A556 GR.A2/GR.B2/GR.C2

STPG370/STPG410/STB340/STB510/STBL380

STBA12/STBA13/STBA20/STBA22/STBA23/STBA24/STBA25

STF340/STFA12/STFA22/STFA23/STFA24

DIN 17175 ST35.8/ST45.8/13CrMo44/10CrMo9-10

EN10216-1 P195 TR1/2,P235 TR1/2,P265TR1/2

EN10216-2 P195GH,P235GH,P265GH,16Mo3,13CrMo4-5,10CrMo9-10Standard ASTM A213/ASME SA213,ASTM A335/ASME SA335, A369, A209, A250; JIS G3462, JIS G3467, DIN17175, BS3059-2, GB/T8162, GB/T6479, GB/T9948, GB5310, ASTM A179/ASME SA179,ASTM A192/ASME SA192, ASTM A334/ASME SA334,etc.

Description

Surface FinishTreatment : Annealing and Pickling, Matt Finish or Satin Finish

Mirror Finish, Wire Drawing or Hairline Finish

Roughness Average : 0.1~0.2μm Outside, 0.3~0.4μm Inside. Ends Finish Plain Ends or Beveled Ends Test Eddy Current/ Hydrostatic/ Ultrasonic/ Intergranular Corrosion

Or according to customers' request

Application: Petroleum, chemical industry, electric power, boiler, high temperature resistant, low temperature resistant, corrosion resistant alloy pipe used. Our company has cooperative relation between the domestic agents. Alloy pipe can be made according to the customers requirements.

Contacts If you have any questions, please feel free to contact me.

A179/A192

A210 GR.A1/GR.C

A209 GR.T1/GR.T1a/GR.T1b

A213 T1/T2/T5/T11/T12/T22

A335 GR.1/GR.6

A556 GR.A2/GR.B2/GR.C2

STPG370/STPG410/STB340/STB510/STBL380

STBA12/STBA13/STBA20/STBA22/STBA23/STBA24/STBA25

STF340/STFA12/STFA22/STFA23/STFA24

DIN 17175 ST35.8/ST45.8/13CrMo44/10CrMo9-10

EN10216-1 P195 TR1/2,P235 TR1/2,P265TR1/2

EN10216-2 P195GH,P235GH,P265GH,16Mo3,13CrMo4-5,10CrMo9-10

Description

Surface Finish

Mirror Finish, Wire Drawing or Hairline Finish

Roughness Average : 0.1~0.2μm Outside, 0.3~0.4μm Inside.

Or according to customers' request

Application: Petroleum, chemical industry, electric power, boiler, high temperature resistant, low temperature resistant, corrosion resistant alloy pipe used. Our company has cooperative relation between the domestic agents. Alloy pipe can be made according to the customers requirements.

Contacts If you have any questions, please feel free to contact me.