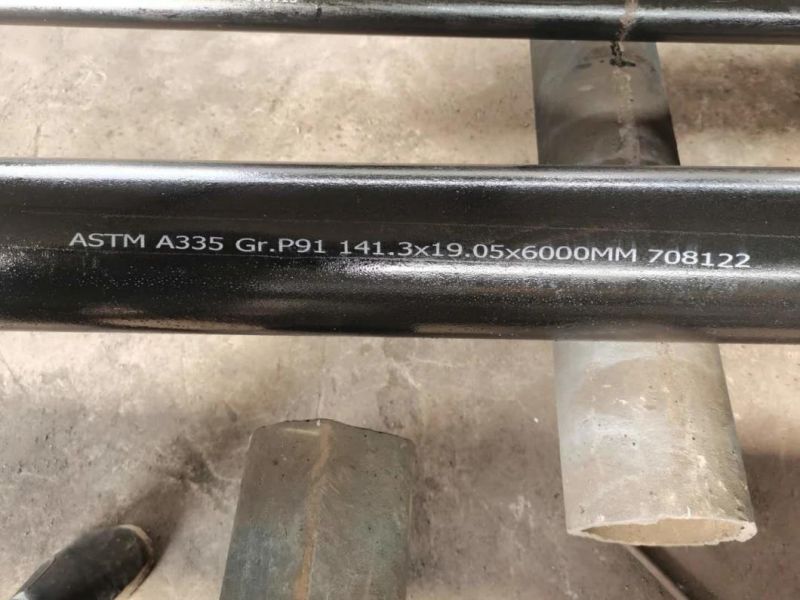

Seamless ASTM A335 Gr P9 P91 P92 Alloy Steel Pipe

Guangzhou Kingmetal Steel Industry Co., Ltd.- Type:Seamless

- Technique:Cold Drawn

- Material:Alloy Steel

- Surface Treatment:Oiled

- Usage:Pipeline Transport, Boiler Pipe, Oil,Gas Drilling

- Section Shape:Round

Base Info

- Model NO.:EL-AP

- Length:1-12m

- Wt:1mm-150mm

- Delivery Time:15-30 Days After Down Payment

- Alloy or Not:Alloy

- Secondary or Not:Non Secondary

- Standard or Not:Standard

- Price Term:Fob, CIF, CNF

- Payment:L,C, T,T

- MOQ:as Requested

- Transport Package:Bundled & Seaworthy

- Specification:18mm-720mm

- Trademark:Kingmetal

- Origin:China

- HS Code:73045110

- Production Capacity:20000 Tons,Month

Description

Basic Info.

Model NO. EL-AP Length 1-12m Wt 1mm-150mm Delivery Time 15-30 Days After Down Payment Alloy or Not Alloy Secondary or Not Non Secondary Standard or Not Standard Price Term Fob, CIF, CNF Payment L/C, T/T MOQ as Requested Transport Package Bundled & Seaworthy Specification 18mm-720mm Trademark Kingmetal Origin China HS Code 73045110 Production Capacity 20000 Tons/MonthProduct Description

Standard: ASTM SA213, SA335, A369, A209, A250; JIS G3462, JIS G3467, DIN17175, BS3059-2, GB/T8162, GB/T6479, GB/T9948, GB5310, etc.

Material:

GB/T: Cr5Mo, 15CrMo, 12Cr1MoV P11/22 T91, P91, P9, T9, Wb36, 42CrMo4/4140/SCM 440

ASTM:

A-335/A199 Gr. P1 /P5 /P9 / P11 /P12 / P22 / P91,

A213T5, T11, T12, T22, P5, P9, P22, P9(SEAMLESS)

A691- 1 1/4CR, 2 1/4CR, 5CR, 9CR etc(WELDED)

DIN: 15Mo3 / 13CrMo44 / 10CrMo910(SEAMLESS)

JIS: STPA12/STPA25/STPA22/STPA24( SEAMLESS)

Application: Petroleum, chemical industry, electric power, boiler, high temperature resistant, low temperature resistant, corrosion resistant alloy pipe used. Our company has cooperative relation between the domestic agents. Alloy pipe can be made according to the customers requirements.

Contacts If you have any questions, please feel free to contact me.

Grade | C | Si | Mn | P | S | Cr | Mo |

P5 | Max.0.15 | Max.0.50 | 0.3-0.6 | Max.0.025 | Max.0.025 | 4-6 | 0.45-0.65 |

P11 | 0.05-0.15 | 0.5-1.0 | 0.3-0.6 | Max.0.025 | Max.0.025 | 1.0-1.5 | 0.44-0.65 |

P12 | 0.05-0.15 | Max.0.50 | 0.3-0.61 | Max.0.025 | Max.0.025 | 0.8-1.25 | 0.44-0.65 |

P22 | 0.05-0.15 | Max.0.50 | 0.3-0.6 | Max.0.025 | Max.0.025 | 1.9-2.6 | 0.87-1.13 |

Grade | Yield point (Mpa) | Tensile strength (Mpa) | Elongation(%) | Impact value(J) |

P5 | ≥205 | ≥415 | See table | ≥35 |

P11 | ≥205 | ≥415 | See table | ≥35 |

P12 | ≥220 | ≥415 | See table | ≥35 |

P22 | ≥205 | ≥415 | See table | ≥35 |