8′′~38′′ ASME SA335 P91 Seamless Steel Pipe for Power Plant

Qingdao Ironsteel International Trading Co., Ltd.- Type:Seamless

- Technique:Hot Rolled

- Material:Alloy Steel

- Surface Treatment:Bare Pipe, Coating by Buyer′s Requirement

- Usage:Pipeline Transport, Oil,Gas Drilling, Chemical Industry, Mining, Special Purpose, Boiler Industry, Power Plant

- Section Shape:Round

Base Info

- Model NO.:IR-B steel pipe

- Diameter:219mm~508mm

- Wall Thickness:10mm~50mm

- Length:Fixed Length, by Random

- Surface:Heat Treatment, Polishing

- End Processing:Plain Ends, Bevel Ends

- Inspection:Third Party Inspection

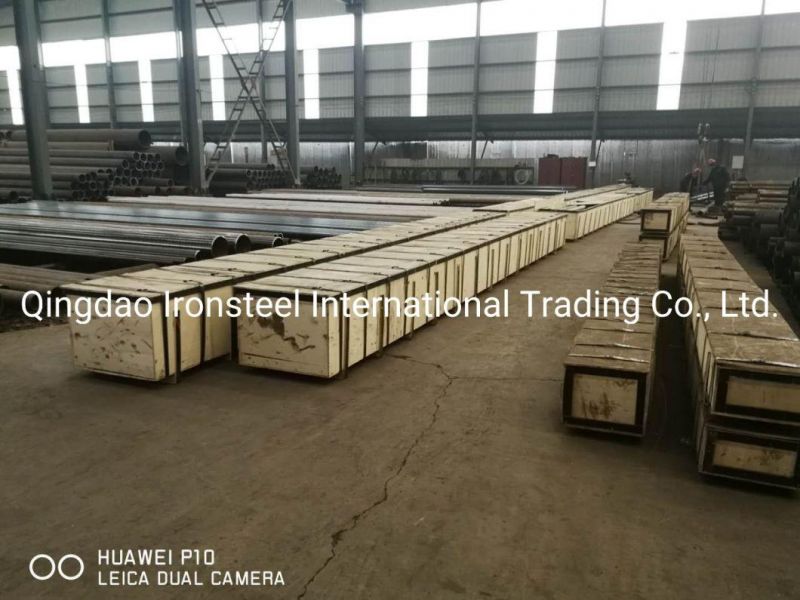

- Transport Package:Standard Seaworthy Packing

- Specification:ASTM A335

- Trademark:Iron&steel

- Origin:China

- HS Code:73045910

- Production Capacity:1000ton Per Month

Description

Mechanical Properties of boiler pipe:

%

SA106

SA333

ASME

SA335

DIN17175

(WB36)

SA106

~0.25

~1.0

~0.27

~1.0

SA333

~0.12

~1.0

~0.12

1.1

ASME

A335

~0.15

~1.0

~0.6

~1.5

~1.0

~0.15

0.6

~1.25

~0.65

~0.15

0.6

~2.6

~1.13

0.6

~6.0

~0.65

~0.12

~0.5

0.6

~9.5

~1.05

~0.25

~0.1

~0.07

~0.13

0.6

~9.5

0.6

0.006

~0.25

~2.0

~0.09

~0.07

17175

~0.35

~1.2

~0.2

~0.35

~0.8

~0.35

~0.18

~0.35

~0.7

~1.1

~0.65

~0.15

~0.7

~2.5

~1.1

0.3

~0.045

-2

~0.5

~1.2

~0.5

~0.8

~1.3

Our service

Make production according to customer's specific requirements strictly.

Accept inspection during the production or before shipment.

Provide the original copy of MTC(Mill testing certificate)

Provide the standard seaworthy packing.

Arrange the most professional shipment