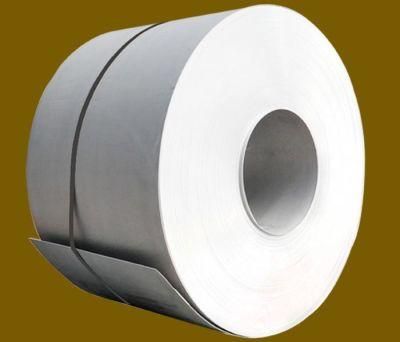

SPCC Dx51 Zinc Cold Rolled/Hot Dipped Galvanized Steel Coil/Sheet/Plate/Strip

LIAOCHENG LUXI DONGHUA FOREIGN TRADE CO., LTD.- Standard:ASTM, JIS, GB, AISI, DIN, BS

- Certification:ISO

- Surface Treatment:Galvanized

- Technique:Cold Rolled

- Application:Container Plate

- Edge:Slit edge

Base Info

- Stock:Stock

- Model No.:Color Coated Prepainted Galvanized Steel Coil PPGI

- Grade:St37-2 A36 S235jr S275jr, St37-2 A36 S235jr S275jr

- Coating Weight:30-600G,M2

- Length:as You Request

- Thickness:0.18mm-6mm

- Width:500mm-2500mm

- Weight:2-8 Ton or as Required

- Ral Color:All

- Surface:Embossed, Mill Finish, Coated

- Trade Term:EXW, Fob, CFR, CIF...

- Coating Process Front:Double Coated&Double Drying, Single Coated&Double

- Certificate:ISO9001,Bam,FM,GS,Ukas

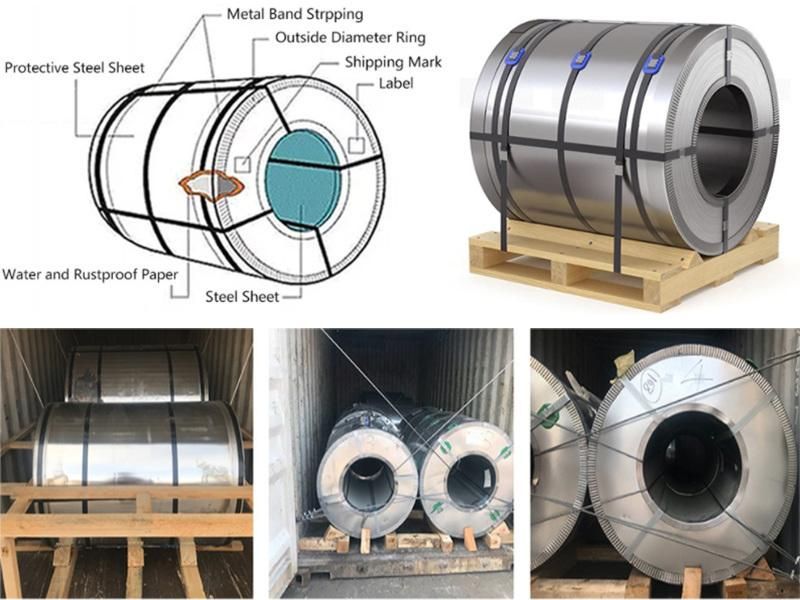

- Transport Package:Standard Export Packing

- HS Code:76109000

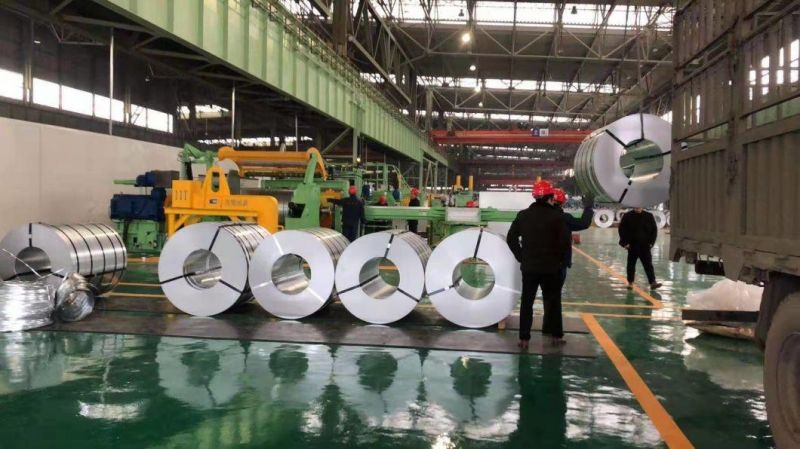

- Production Capacity:40000ton,Month

Description

STEEL COILSteel standard: ASTM, AISI, JIS, DIN, EN, GB, BS, Steel grade: SGCC,SGCH,SGC340, SGC440,SGC490, SGC570, G550,DX51D,DX52D,DX53D, Q195,Q235, Q345, etc. Zinc/Alu-Zinc content: 20-600g/m2 Thickness: 0.12-6mm Width: 350-2500mm Weight: 2t-8t Surface pattern: Zero spanle, small spangle, regular spangle, large spangle

1. Construction: steel framing, false ceilings, sandwich panels, ducting, decking, purlin, HVAC applications, doors, cladding/siding/facade/roofing, building accessories, sliding shutter, canopies of gas stations, prefabricated buildings, bill boards.

2. Household appliance: refrigerators, deep freezers, washing machines, air coolers, cooking oven.

3. Automotive: auto internal components, bus bodies.

4. Furniture: office equipment.

5. Container: grain silos, drums & barrels, crash guards/ handrails.

etc.

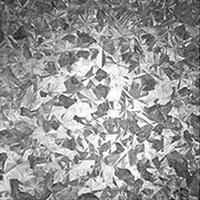

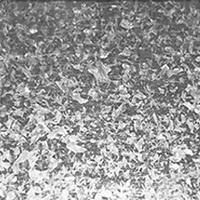

GI/GL pictureZero spanle small spangle regular spangle large spangle

GI/GL feature

1. Stable Quality:

we use our excellent equipment and technology and vast experience to manufacture products with stable quality under strict control throughout all process including pig iron manufacturing, steel manufacturing, heating, rolling and cooling.

2. Flawless Surface:

Using material (slabs) manufactured under a strict quality control system, we manufacture steel plates with flawless surface by removing scales from the steel plates with high pressure water jets during the rolling process. In addition, in the transport and heat treatment, etc. of steel plates, manufacturing is conducted using state-of-the-art equipment.

3. Wide availability:

We provide a wide product availability including steel plates that satisfy official standards in Japan and overseas, high tensile strength steel for welded structures, abrasion resistant steel, atmospheric corrosion resistant steel, low-temperature service steel, and steel for building, as well as materials that are suitable for a wide variety of uses,from offshore structures (production), line pipes (transport) tanks (storage) and other high-function steel for use in energy fields. In addition, we also accept orders for steel with special specifications, such as extra-thick steel plates for molds, electromagnetic soft iron, and chromium molybdenum steel for use in high temperatures. we also provide shot blasting and primer coating upon request. We also manufacture extra-heavy thick steel plates for use in nuclear power plants, thermal power plants, hydraulic power plants, petrochemical plants and the like.

4. On-time Delivery:

We strive for on-time delivery by making the most of the advantageous seaside location of each steel mill and our control systems for each individual product under process control that effectively utilizes a computer system.

5. Precise Consulting:

The engineering divisions at our head office and various branch offices canprecisely provide consulting on the quality characteristics, applications, and processing methods of steel plates as well as technical cooperation during use, based on their vast experience and comprehensive technical capabilities.

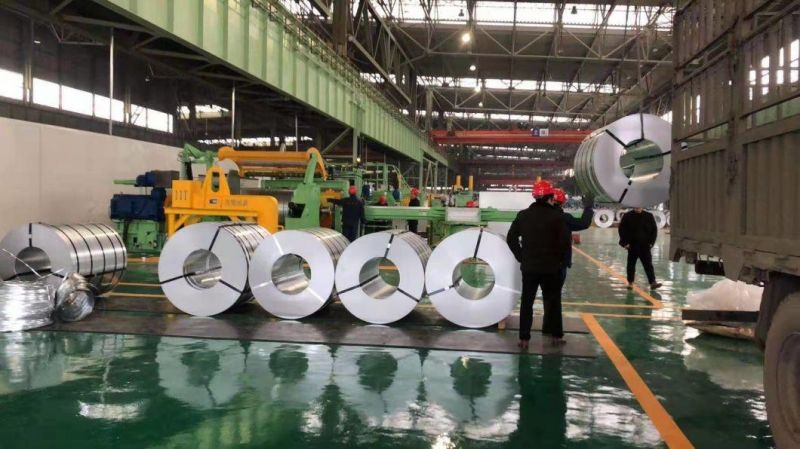

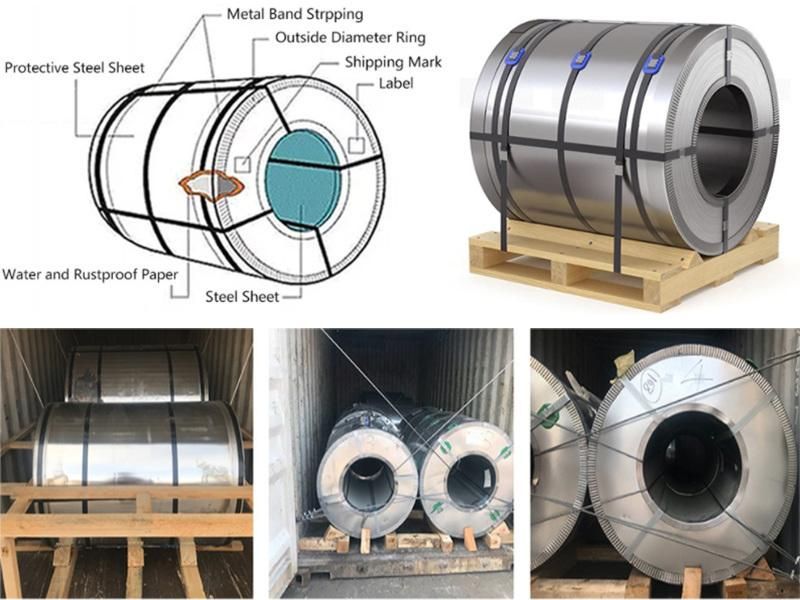

Loading & delivery

Three layers of packing, inside layer is kraft paper, middle layer is water plastic film, outside layer is steel strips.load by wooden pallet.

FAQ

FAQ

Why choose your company?

We are specialized in this industry for more than 8 years.We have a professional sales team with best service.

Can you provide OEM/ODM service?

Yes.Please feel free to contactus for more details discuss.

Can you provide sample?

Yes,for regular size of samples,it,s for free but buyer need to play freight cost

What's the MOQ?

1 ton is OK.

What's the surface coating?

An tirusted painting,varnish painting,galvanized,3LPE,3PP,Zinc oxide yellow primer,zinc phosphate primer and as per customers'

request.

What's your delivery time ?

Regular leading time is 7 to 15 days after receiving deposit.

Can we visit your factory?

Warmly welcome.once you have any schedule to China,we will pick you up from airport or station to your factory.

1.DEEP DRAWIN

2.HIGH COATING

3.HIGH TENSILE

4.SLITTED STRIP

5EXTREME SPECIFICATION.

GI/GL application1. Construction: steel framing, false ceilings, sandwich panels, ducting, decking, purlin, HVAC applications, doors, cladding/siding/facade/roofing, building accessories, sliding shutter, canopies of gas stations, prefabricated buildings, bill boards.

2. Household appliance: refrigerators, deep freezers, washing machines, air coolers, cooking oven.

3. Automotive: auto internal components, bus bodies.

4. Furniture: office equipment.

5. Container: grain silos, drums & barrels, crash guards/ handrails.

etc.

GI/GL picture

GI/GL feature

1. Stable Quality:

we use our excellent equipment and technology and vast experience to manufacture products with stable quality under strict control throughout all process including pig iron manufacturing, steel manufacturing, heating, rolling and cooling.

2. Flawless Surface:

Using material (slabs) manufactured under a strict quality control system, we manufacture steel plates with flawless surface by removing scales from the steel plates with high pressure water jets during the rolling process. In addition, in the transport and heat treatment, etc. of steel plates, manufacturing is conducted using state-of-the-art equipment.

3. Wide availability:

We provide a wide product availability including steel plates that satisfy official standards in Japan and overseas, high tensile strength steel for welded structures, abrasion resistant steel, atmospheric corrosion resistant steel, low-temperature service steel, and steel for building, as well as materials that are suitable for a wide variety of uses,from offshore structures (production), line pipes (transport) tanks (storage) and other high-function steel for use in energy fields. In addition, we also accept orders for steel with special specifications, such as extra-thick steel plates for molds, electromagnetic soft iron, and chromium molybdenum steel for use in high temperatures. we also provide shot blasting and primer coating upon request. We also manufacture extra-heavy thick steel plates for use in nuclear power plants, thermal power plants, hydraulic power plants, petrochemical plants and the like.

4. On-time Delivery:

We strive for on-time delivery by making the most of the advantageous seaside location of each steel mill and our control systems for each individual product under process control that effectively utilizes a computer system.

5. Precise Consulting:

The engineering divisions at our head office and various branch offices canprecisely provide consulting on the quality characteristics, applications, and processing methods of steel plates as well as technical cooperation during use, based on their vast experience and comprehensive technical capabilities.

Loading & delivery

Three layers of packing, inside layer is kraft paper, middle layer is water plastic film, outside layer is steel strips.load by wooden pallet.

FAQ

FAQWhy choose your company?

We are specialized in this industry for more than 8 years.We have a professional sales team with best service.

Can you provide OEM/ODM service?

Yes.Please feel free to contactus for more details discuss.

Can you provide sample?

Yes,for regular size of samples,it,s for free but buyer need to play freight cost

What's the MOQ?

1 ton is OK.

What's the surface coating?

An tirusted painting,varnish painting,galvanized,3LPE,3PP,Zinc oxide yellow primer,zinc phosphate primer and as per customers'

request.

What's your delivery time ?

Regular leading time is 7 to 15 days after receiving deposit.

Can we visit your factory?

Warmly welcome.once you have any schedule to China,we will pick you up from airport or station to your factory.